10

e. A hot water boiler installed above radiation level

must be provided with a low water cutoff device

as part of the installation.

If a low water cut-off is required, it must be

mounted in the system piping above the boiler.

The minimum safe water level of a hot water

boiler is just above the highest water containing

cavity of the boiler; that is, a hot water boiler

must be full of water to operate safely.

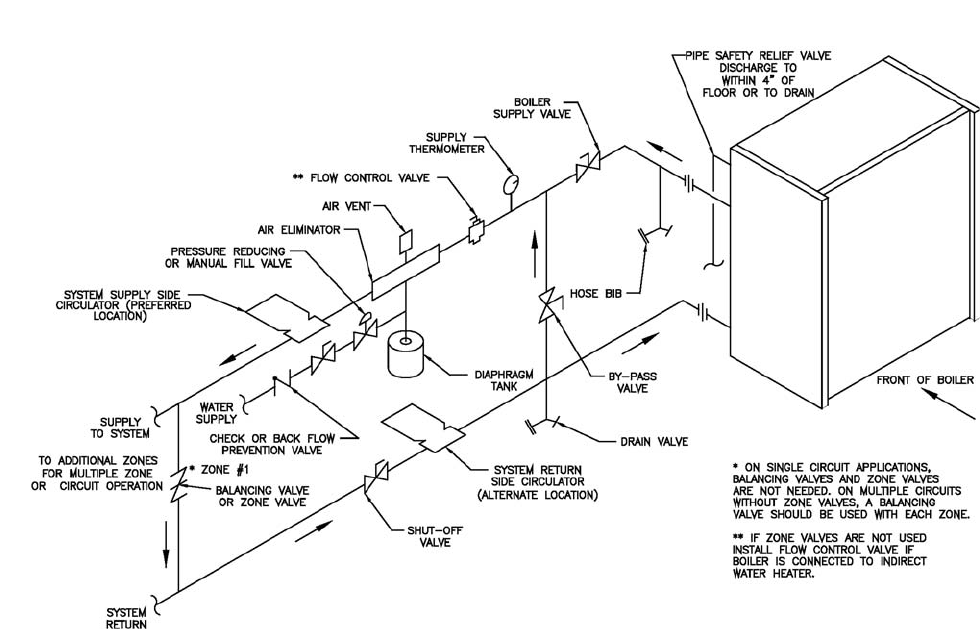

f. Use a boiler bypass if the boiler is to be

operated in a system which has a large volume

or excessive radiation where low boiler water

temperature may be encountered (i.e., converted

gravity circulation system, etc.). The bypass

should be the same size as the supply and return

lines with valves located in the by-pass and

supply outlet as illustrated in order to regulate

water fl ow for maintenance of higher boiler

water temperatures. See Figure 6.

Set the by-pass and boiler supply valves to a

half throttle position to start. Operate boiler

until the system water temperature is at a normal

operating range.

Adjust the valves to provide 180° to 200°F

supply water temperature. Opening the boiler

supply valve will raise the system temperature,

while opening the by-pass valve will lower the

system supply temperature.

If it is required to perform a long term pressure

test of the hydronic system, the boiler should fi rst

be isolated to avoid a pressure loss due to the

escape of air trapped in the boiler.

To perform a long term pressure test including

the boiler, ALL trapped air must fi rst be removed

from the boiler.

A loss of pressure during such a test, with no

visible water leakage, is an indication that the

boiler contained trapped air.

7 INSTALL BOILER FLUSH JACKET (See Figure

9).

a. Open jacket carton and locate side panels. Note that

jacket left side panel is not insulated and right side

panel is insulated.

b. Position the rear fl ange on jacket left side panel

behind the boiler back plate. Position fl ange support

notches over jacket support hooks on back panel

and engage jacket on both support hooks to keep the

panel from moving front to rear.

c. Position rear fl ange on jacket right side panel behind

upper and lower jacket support brackets. Engage

jacket with jacket support hooks in similar manner

as left side panel to provide proper positioning and

support.

d. Take jacket top and bottom panel from carton. Top

panel can be identifi ed by the front channel used to

Figure 6

RECOMMENDED BOILER PIPING