CAUTION: Failure to follow these precautions could

result in damage to the unit being installed:

1. Make all electrical connections in accordance with

NEC ANSI/NFPA 70 (latest edition) and local electri-

cal codes governing such wiring. In Canada, all elec-

trical connections must be in accordance with CSA

standard C22.1 Canadian Electrical Code Part 1 and

applicable local codes. Refer to unit wiring diagram.

2. Use only copper conductor for connections between

field-supplied electrical disconnect switch and unit. DO

NOT USE ALUMINUM WIRE.

3. Be sure that high-voltage power to unit is within

operating voltage range indicated on unit rating plate.

4. Do not damage internal components when drilling

through any panel to mount electrical hardware, con-

duit, etc.

5. On 3-phase units, ensure phases are balanced within

2%. Consult local power company for correction of

improper voltage and/or phase imbalance (refer to

Table 5).

A. HIGH-VOLTAGE CONNECTIONS

The unit must have a separate electrical service with a field-

supplied, water-proof, disconnect switch mounted at, or within

sight from the unit. Refer to the unit rating plate for maximum

fuse/ circuit breaker size and minimum circuit amps (ampacity) for

wire sizing. See Table 5 for electrical data.

The field-supplied disconnect switch box may be mounted on the

unit over the high-voltage inlet hole when the standard power and

low-voltage entry points are used. See Fig. 6 and 7 for acceptable

location.

See unit wiring label and Fig. 14 for reference when making high

voltage connections. Proceed as follows to complete the high-

voltage connections to the unit.

1. Run the high-voltage (L1, L2, L3) and ground leads into the

control box.

2. Connect ground lead to chassis ground connection.

3. Locate the black and yellow wires connected to the lines

side of the contactor.

4. Connect field L1 to black wire on connection 11 of the

compressor contactor.

5. Connect field wire L2 to yellow wire on connection 13 of

the compressor contactor.

6. Connect field wire L3 to Blue wire from compressor.

B. Special Procedures For 208-V Operation

WARNING: Make sure that the gas supply then the

power supply to the unit is switched OFF before making

any wiring changes. Electrical shock or explosion could

cause serious injury or death.

With disconnect switch open, move yellow wire from transformer

(3/16 in.) terminal marked 230 to terminal marked 200. This retaps

transformer to primary voltage of 208 vac.

C. CONTROL VOLTAGE CONNECTIONS

NOTE: Do not use any type of power-stealing thermostat. Unit

control problems may result.

Use no. 18 American Wire Gage (AWG) color-coded, insulated

(35° C minimum) wires to make the control voltage connections

between the thermostat and the unit. If the thermostat is located

more than 100 ft from the unit (as measured along the control

voltage wires), use no. 16 AWG color-coded, insulated (35° C

minimum) wires.

STANDARD CONNECTION — Remove knockout hole located

in the flue panel adjacent to the control access panel. See Fig. 6

and 7. Remove the rubber grommet from the installer’s packet

(included with unit) and install grommet in the knockout opening.

Provide a drip loop before running wire through panel.

Run the low-voltage leads from the thermostat, through the inlet

hole, and into unit low-voltage splice box.

Locate five 18-gauge wires leaving control box. These low-voltage

connection leads can be identified by the colors red, green, yellow,

brown, and white. (See Fig. 14.) Ensure the leads are long enough

to be routed into the low-voltage splice box (located below right

side of control box). Stripped yellow wire is located in connection

box. Route leads through hole in bottom of control box and make

low-voltage connections as shown in Fig. 14. Secure all cut wires,

so that they do not interfere with operation of unit.

HEAT ANTICIPATOR SETTING — The room thermostat heat

anticipator must be properly adjusted to ensure proper heating

performance. Set the heat anticipator, using an ammeter between

the W and R terminals to determine the exact required setting.

NOTE: For thermostat selection purposes, use 0.18 amp for the

approximate required setting.

Failure to make a proper heat anticipator adjustment will result in

improper operation, discomfort to the occupants of the conditioned

space, and inefficient energy utilization; however, the required

setting may be changed slightly to provide a greater degree of

comfort for a particular installation.

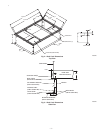

Fig. 11—Supply and Return Duct Opening

C99089

SUPPLY

DUCT

OPENING

RETURN

DUCT

OPENING

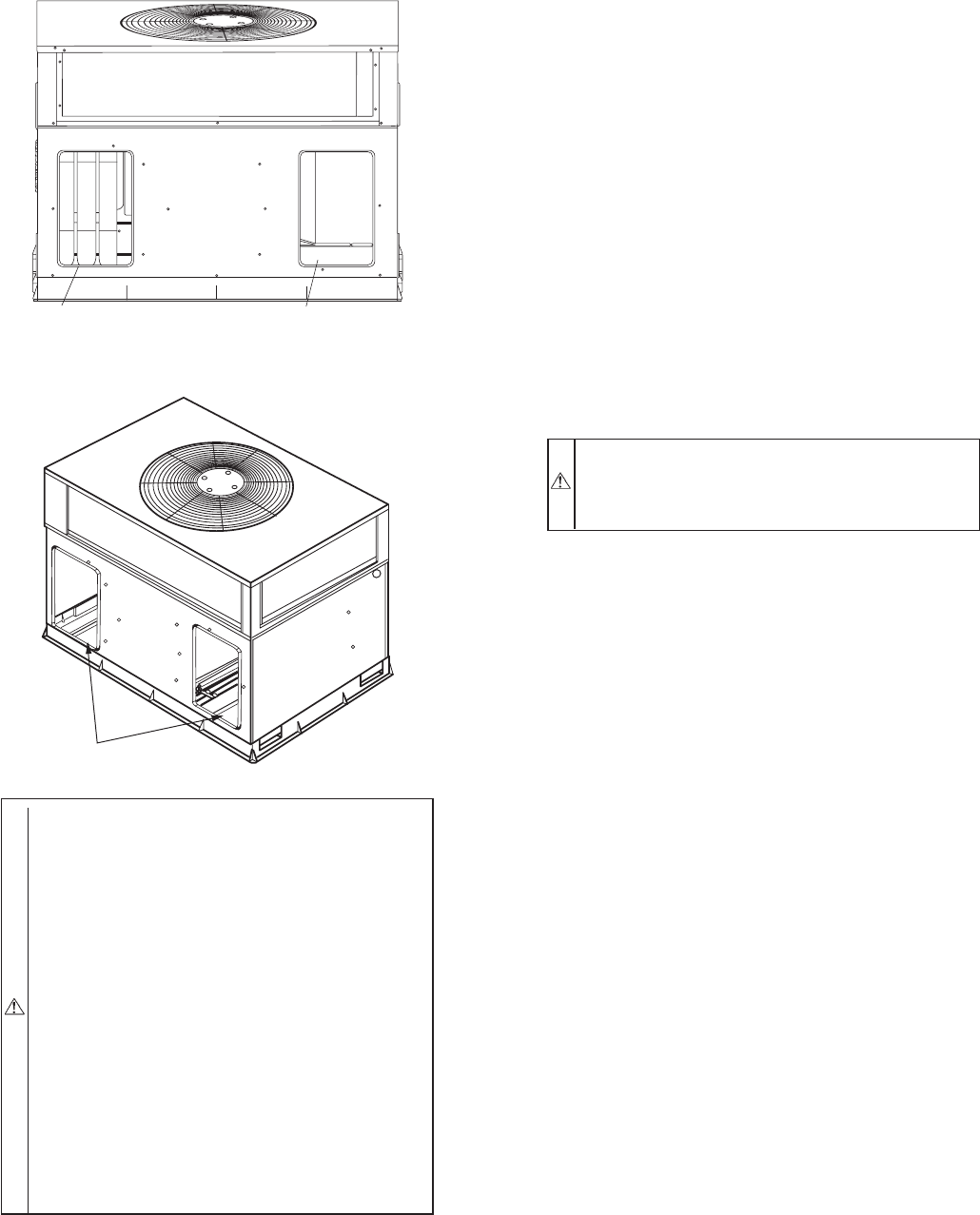

Fig. 12—Vertical Duct Cover Removed

C99012

DUCT COVERS REMOVED

—11—