264

APPLICATION DATA (cont)

c. E-COATED ALUMINUM FIN coils undergo a precisely

controlled scientific process that bonds an impermeable

epoxy coating to the specially prepared fin coil surface.

E-Coating produces a smooth, consistent coating that is

less brittle, more resilient and more durable than previ-

ous postcoating processes. E-Coated aluminum-fin coils

offer economical protection and improved coil life in

many contaminated environments.

d. E-COATED COPPER-FIN COILS provide maximum pro-

tection in virtually all environments, this option combines

the continuous, impenetrable barrier of the E-Coating

process with the natural resistance of an all-copper con-

struction. E-Coated copper-fin coil assemblies ensure

long life, even in environments that combine harsh

coastal conditions with industrial contamination.

16. ECONOMI$ER IV — The EconoMi$er IV factory-installed

economizer package includes a gear-driven damper sys-

tem that modulates the return air and outdoor air supply to

the rooftop unit in order to take advantage of “free cooling”

with outdoor air when conditions are suitable. The system

utilizes industry proven technology available for integrating

the use of outdoor air for cooling with mechanical cooling

for 3 through 25-ton rooftop units. The intuitive

EconoMi$er IV microprocessor-based controller optimizes

and enhances rooftop operation through reduced energy

consumption, optimal zone comfort, and efficient equip-

ment cycling. This is accomplished by operating the com-

pressors when the outdoor air temperature is too warm,

integrating the compressors with outdoor air when free

cooling is available, and locking out the compressor when

outdoor air temperature is too cold. The detailed sequence

of operation is described in the Controls section with a brief

description of selected application items here.

a. THERMOSTAT INTERFACE — The EconoMi$er IV con-

trol was designed to work with conventional thermostats

that have Y1 (cooling stage 1), Y2 (cooling stage 2), W1

(heat stage 1), W2 (heat stage 2), and G (fan). In addi-

tion, the EconoMi$er IV will support an occupied/

unoccupied switch (typically integrated into the thermo-

stat or Thermidistat™ device). When the switch is

closed, it provides a 24-vac signal to the unit for occu-

pied mode, and provides no signal to indicate unoccu-

pied mode. The EconoMi$er IV control can be

configured to allow different minimum economizer

damper positions and to allow the use of mechanical

cooling in the occupied mode.

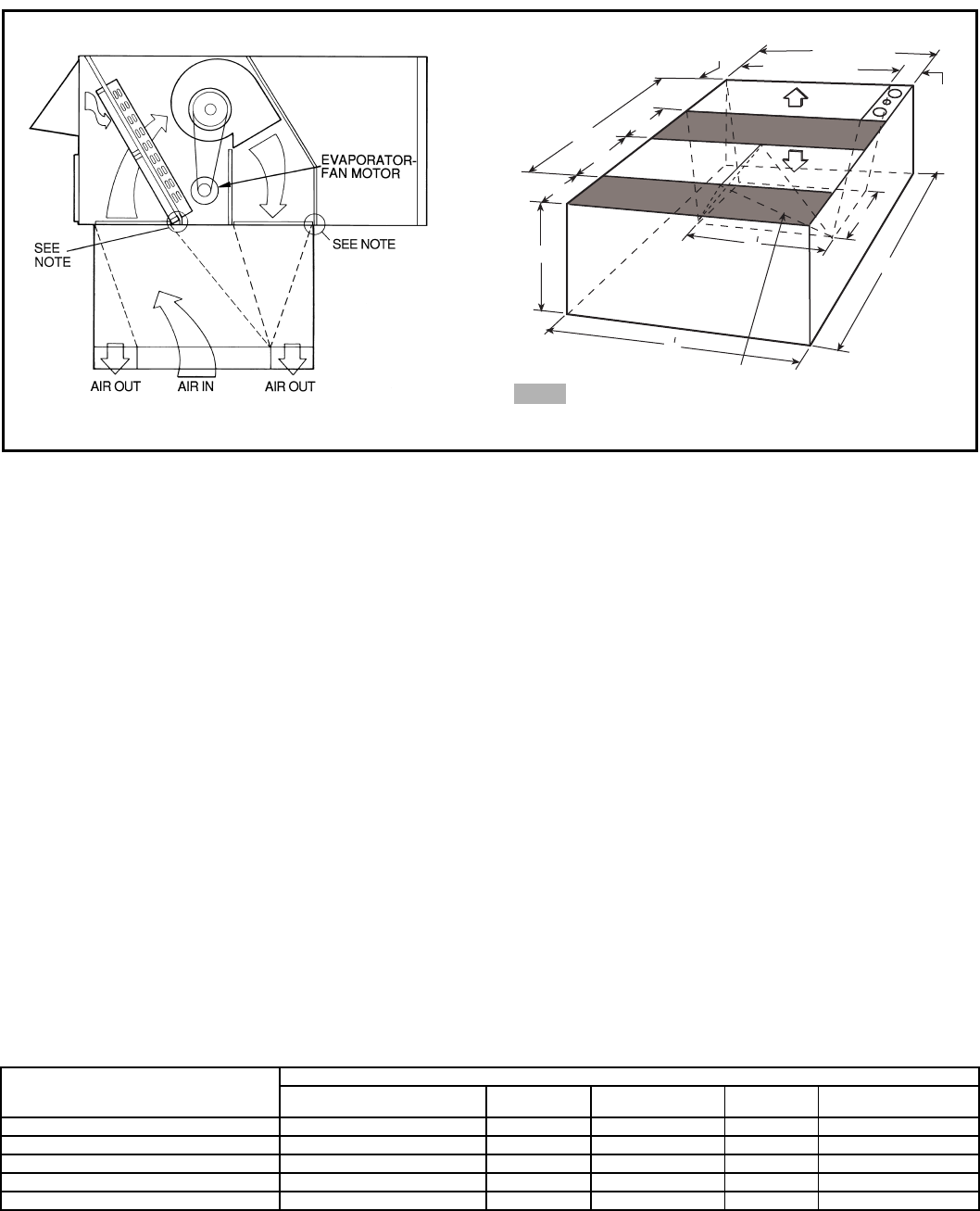

CONDENSER COIL PROTECTION APPLICATIONS

LEGEND

CONCENTRIC DUCT DISTRIBUTION

CONCENTRIC DUCT DETAILS

NOTE: Do not drill in this area, damage to basepan may result in

water leak.

6'-2 3/8'' MAX.

5'-9 3/16'' MAX.

5 3/16''

B

A

BAFFLE

A

B

24'' MIN.

1'-0 3/16''

1'-7 15/16''

4'-6 13/16''

1'-0 3/16''

1'-10 11/16''

MAX.

Shaded area indicates block-off panels.

NOTE: Dimensions A, A′ and B, B′ are obtained from field-supplied

ceiling diffuser.

Concentric Duct Details

a48-7482

a50-530

DESCRIPTION

(Dura-Shield Option)

ENVIRONMENT

Standard, Non-Corrosive Mild Coastal Severe Coastal Industrial

Combined Coastal

and Industrial

Standard, Al/Cu X

Pre-Coated Al/Cu X

Cu/Cu X

E-Coated Al/Cu XX

E-Coated Cu/Cu X

Al/Cu — Aluminum Fin with Copper Tube Coil E-Coated — Extremely Flexible and Durable Epoxy Coating Uniformly

Cu/Cu — Copper Fin with Copper Tube Coil Applied to the Coil Surfaces

Dura-Shield — Family of Coil Protection Options Pre-Coated — Epoxy Coating Applied to Fin Stock Material