5

Step 7 — Make Piping Connections

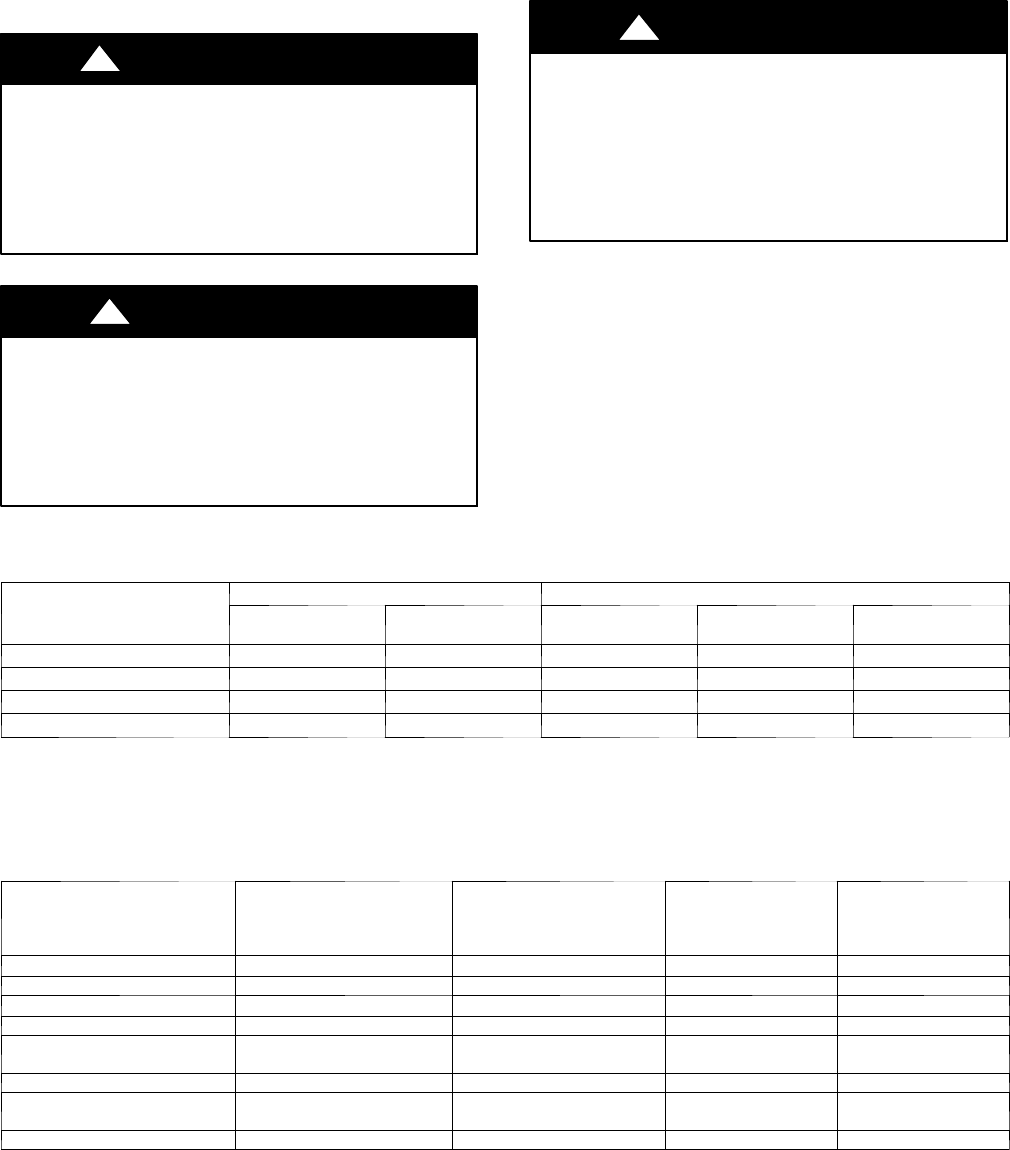

!

WARNING

PERSONAL INJURY AND UNIT DAMAGE

HAZARD

Failure to follow thiswarning could result in personal injury or

death.

Relieve pressure and recover all refrigerant before system

repair or final unit disposal. Use all service ports and open all

flow--control devices, including solenoid valves.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

Do not leave system open to atmosphere any longer than

minimum required for installation. POE oil in compressor is

extremely susceptible to moisture absorption. Always keep

ends of tubing sealed during installation.

CAUTION

!

UNIT DAMAGE HAZARD

Failure to follow this caution may result in equipment

damage or improper operation.

If ANY refrigerant tubing is buried, provide a 6 in. (152.4

mm) vertical rise at service valve. Refrigerant tubing lengths

up to 36 in. (914.4 mm) may be buried without further

special consideration. Do not bury lines longer than 36 in.

(914.4 mm).

Outdoor units may be connected to indoor section using accessory

tubing package or field--supplied refrigerant grade tubing of correct

size and condition. For tubing requirements beyond 80 ft. (24.38

m), substantial capacity and performance losses can occur. Follow

the pipe sizing recommendations in the 280ANV Product data to

manage these losses.

Refer to Table 1 for field tubing diameters. Refer to Table 2 for

accessory requirements.

Table 1 – Refrigerant Connections and Recommended Liquid and Vapor Tube Diameters (in.)

UNIT SIZE

LIQUID VAPOR*

Connection

Diameter

Tube

Diameter

Connection

Diameter

Max (Rated)

Diameter

Minimum Tube

Diameter

280ANV024

3/8 3/8 7/8 7/8 5/8

280ANV036

3/8 3/8 7/8 7/8 5/8

280ANV048

3/8 3/8 7/8 1 --- 1/8 3/4

280ANV060

3/8 3/8 7/8 1 --- 1/8 3/4

* Unitsare rated with 25ft. (7.6 m) oflineset.See Product Data sheet for performance data when using different size and length line sets.

Notes:

1. Donot applycapillarytube indoorcoils totheseunits.

2. For Tubing Set lengths between 80 and 200 ft.( 24.38 and 60.96 m) horizontal and / orgreater than 20 ft. (6.1 m) vertical differential, an accessory Liquid Line

Solenoidmustbe installed.

Table 2 – Accessory Usage

ACCESSORY

REQUIREDFOR

LOW--- AMBIENT COOLING

APPLICATIONS

(Below55F/12.8_C)

REQUIRED FOR LONG LINE

APPLICATIONS*

(Over 80 ft/24.38 m)

REQUIRED FOR SEA

COAST APPLICATIONS

(Within 2 miles/3.22 km)

Installations withR adio

Frequency Interference

Concerns in the Range

of2to30MHZ

Crankcase Heater Standard

Standard

Standard Standard

Evaporator Freeze Protection Standard with Evolution Control No No No

Liquid---Line Solenoid Valve No

Yes

No No

Low---Ambient Control Standard with Evolution Control No No No

Puron Refrigerant Balance Port

Hard ---ShutOff TXV

Yes{

Yes{

Yes{ Yes{

SupportFeet Recommended No Recommended No

WinterStartControl

Standardwith Evolution

Control

Standardwith Evolution

Control

Standardwith Evolution

Control

Standardwith Evolution

Control

EMI Kit No No No Yes

* For tubing setlengths between 80 and200 ft. (24.38 and 60.96m) horizontal or 20 ft. (6.10 m) vertical differential (total equivalent length), an accessory

Liquid Line Solenoid must be installed.

{ Required on all indoorunits. Standardon all new Puronrefrigerantfan coilsand furnacecoils.

Standard =Standard for all new Puron refrigerant fancoilsand furnace coils.