12

MAJOR COMPONENTS

Variable speed Control Board

The HP control board controls the following functions:

S Compressor speed

S Contactor operation

S Outdoor fan motor operation

S Reversing valve operation

S Defrost operation

S Low ambient cooling

S Crankcase heater operation

S Pressure switch monitoring

S Time Delays

S Pressure Transducer

S .EXV operation control

S .Inverter communication and control

Inverter

The inverter is located inside the control box. This is an air--cooled

device that communicates with the control board and drives the

compressor to the demanded RPM. When the contactor closes, it

powers the inverter with line voltage. The inverter converts the line

voltage to 410 volts DC. The inverter then converts DC voltage

into 3--phase variable frequency and variable voltage.

NOTE: Manually closing the contactor will not cause the unit to

operate. The unit must be operated with an Evolution Control. A

standard thermostat will allow operation only in the emergency

mode (high speed heating or cooling).

Motor Control Drive

(Inverter):

S Converts the sinusoidal AC input mains voltage into a variable

frequency AC output generated used PWM modulation of the

output.

S Drive adjusts the output voltage to run the compressor at the

correct speed at any load point in the envelope.

S The drive actively controls the motor current to insure the proper

torque is provided for the given loading condition.

S The drive control algorithms insure the magnetic field set up in

the motor is synchronized with the rotor insuring smooth

efficiency operation.

S The drive actively controls the input current at heavy loading

conditions to insure the input power factor to the drive is >0.95.

Variable Speed Compressor

This unit contains a variable speed compressor that has a wide

operating range. This compressor can only be operated by the

specific inverter supplied with the unit.

Motor Control Drive + BPM

together:

S Through the combination of the drive and motor, the

system is able to operate over a wide speed range.

S The drive provides protection of the system to various

abnormal conditions including limiting the compressor

envelope of operation to appropriate boundaries.

S Provides many pieces of system data as feedback to the

system controller.

S Allows operation at least than full performance in case of

system faults or issues.

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

and/or improper operation.

Do not attempt to apply line voltage directly to the

compressor. This will destroy the compressor.

CAUTION

!

Compressor Brush--less Permanent Magnet Motor (BPM):

S The motor inductance reacts to the drive current and a sinusoidal

current is induced through the motor windings.

S The sinusoidal current sets a rotating magnetic field, at the

frequency set by the drive.

S The magnets enable the motor to synchronize to that frequency,

set by the drive.

S Suppliesthemechanicalpower afforded toitby thedrivevoltage,

current and frequency.

Electronic Expansion Valve (EXV)

This unit uses an electronic expansion valve for refrigerant

metering in the heating mode. The control board drives the EXV to

its proper position based on the operating mode and conditions.

The Evolution Control Service mode allows for manual opening

and closing of the EXV for troubleshooting and pump down.

Field control Connections

For normal operation use the ABCD Evolution connections only.

Only two wires, AB arerequired. See Fig. 18. Discrete inputs (Y,C,

O) are available for emergency operation if the Evolution Bus is

not in operation.

Pressure Transducer (SPT)

A 5 VDC output low pressure transducer that provides a 0--5 VDC

data for interpretation by the control board for a 0 to 200 psig

range of pressure at the suction tube. This interpreted pressure data

is then intelligently used by the control board for low pressure

cut--out, loss of charge management, compressor overall envelope

management, oil circulation management, lubrication management

and EXV control. (See Fig. 17.)

Compressor Control Contactor

The contactor has a 24 volt coil. The electronic control board

controls the operation of the contactor.

TROUBLESHOOTING

Systems Communication Failure

If communication with the Evolution control is lost with the User

Interface (UI), the control will flash the appropriate fault code (see

Table 7). Check the wiring to the User Interface and the indoor and

outdoor units and power.

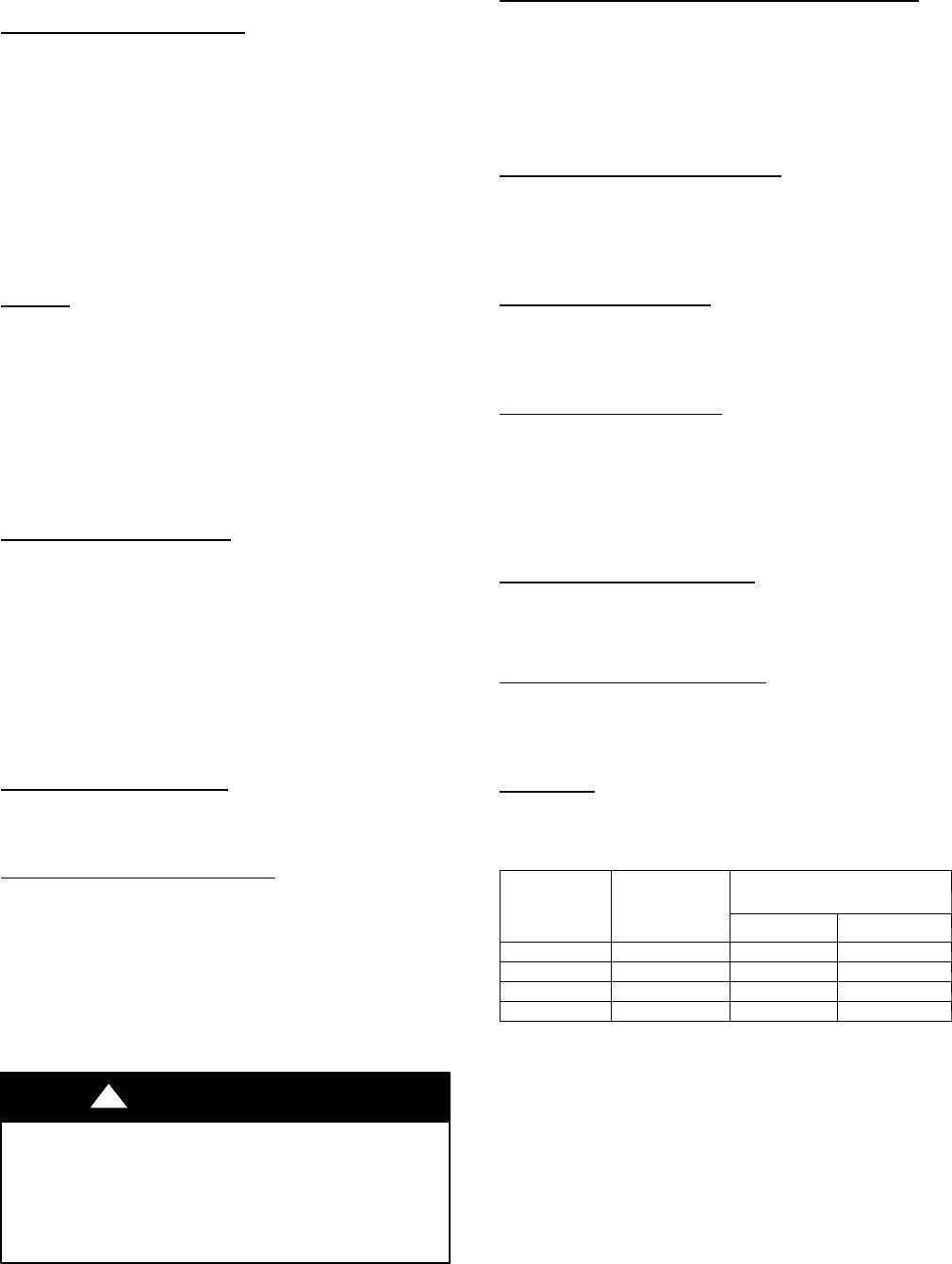

Model Plug

Each control board contains a model plug. The correct model plug

must be installed for the system to operate properly (see Table 3).

Table 3 – Model Plug Information

MODEL

NUMBER

MODEL PLUG

NUMBER

PIN RESISTANCE

(K --- ohms)

Pins 1 --- 4 Pins 2---3

280ANV024 HK70EZ001 5.1K 11K

280ANV036 HK70EZ002 5.1K 18K

280ANV048 HK70EZ003 5.1K 24K

280ANV060 HK70EZ004 5.1K 33K

The model plug is used to identify the type and size of unit to the

control.

On new units, the model and serial numbers are input into the

board’s memory at the factory. If a model plug is lost or missing at

initial installation, the unit will operate according to the

information input at the factory and the appropriate error code will

flash temporarily. An RCD replacement board contains no model

and serial information. If the factory control board fails, the model

plug must be transferred from the original board to the replacement

board for the unit to operate.

NOTE: The model plug takes priority over factory model

information input at the factory. If the model plug is removed after

initial power up, the unit will operate according to the last valid

model plug installed, and flash the appropriate fault code

temporarily.