Page 4 RWB 6104 BNX R02

General Specifi cations

Table 1 – Burner Specifi cations

Capacity Firing rate: - 0.40 – 1.75 GPH

Input: Min. - 56,000 Btu

Max - 245,000 Btu

Certifi cation/

Approvals

UL certifi ed to comply with ANSI/UL296 &

tested to CSA B140.0

Fuels U. S No. 1 or No. 2 heating oil only (ASTM

D396)

Canada No. 1 stove oil or No. 2 furnace oil

only

Electrical Power supply - 120 volts AC, 60 Hz, single

phase

Operating load - 5.8 Amps max

Motor - 1/7 hp, 3450 rpm, NEMA 48M

frame PSC rotation CCW when

facing shaft end

Ignition - Continuous duty solid-state igniter

Fuel pump Outlet pressure - Note 1

Air tube ATC code - See Table 2

Dimensions

(with cover)

Height (maximum) - 12-1/2 inches

Width (maximum) - 15 inches

Depth - 9-1/4 inches

Air tube diameter - 3-1/4 inches

*Note 1. See appliance manufacturer’s burner specifi cations for

recommended outlet pressure.

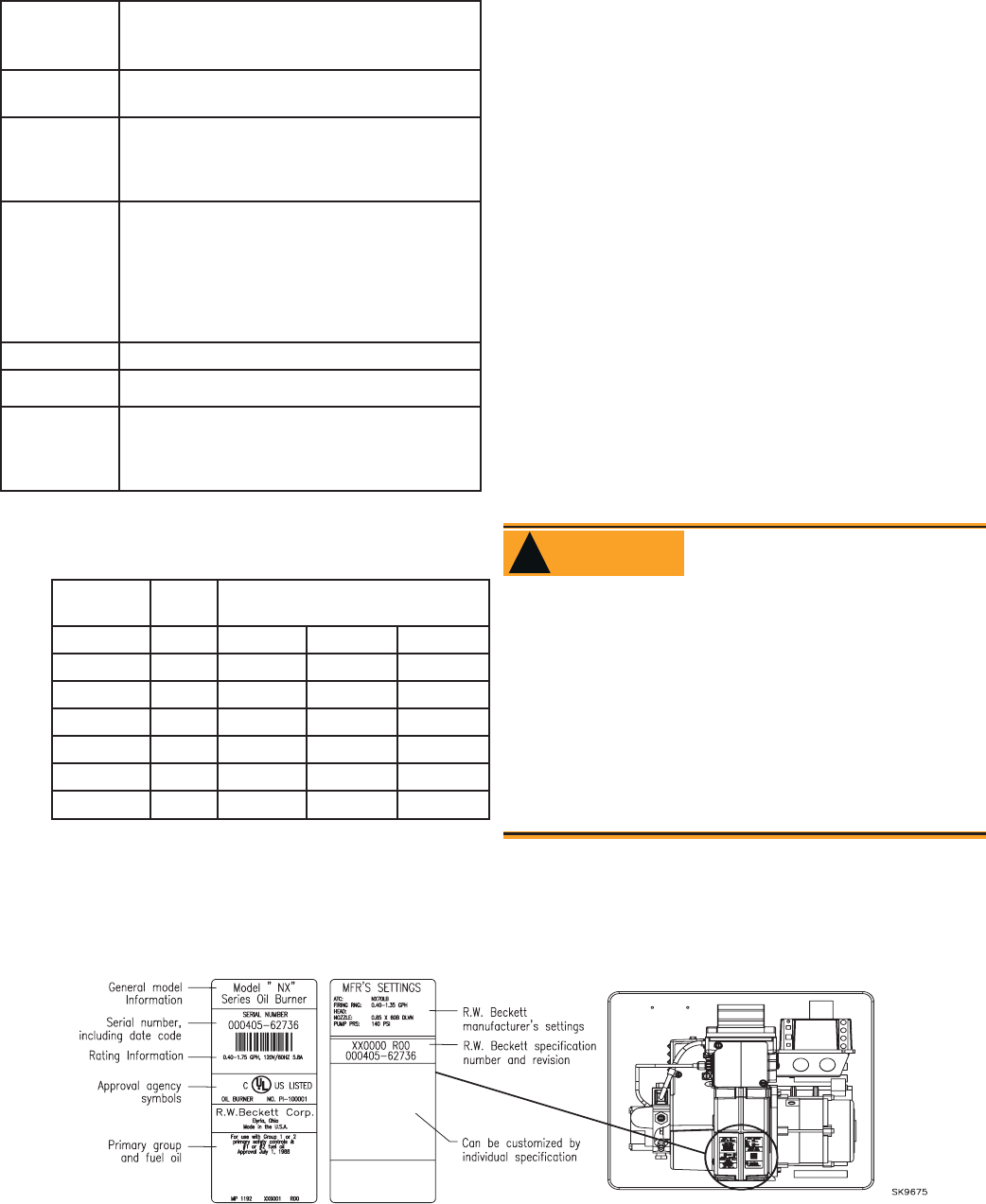

Table 2 – Air Tube Combinations (ATC)

Firing rate

(gph)

Head ATC codes for usable air tube

lengths:

(min-max) 5” 7” 9”

0.40-1.00 9-Slot NX50LG NX70LG NX90LG

0.40-1.00 6-Slot NX50LH NX50LH NX90LH

0.40-1.35 9-Slot NX50LB NX70LB NX90LB

0.40-1.35 6-Slot NX50LC NX70LC NX90LC

1.10-1.75 9-Slot NX50LD NX70LD NX90LD

1.10-1.75 6-Slot NX50LF NX70LF NX90LF

•

Notice Special Requirements

For recommended installation practice in Canada,

refer to the latest version of CSA Standard B139 &

B140.

Concealed damage — If you discover damage to

the burner or controls during unpacking, notify the

carrier at once and fi le the appropriate claim.

When contacting Beckett for service information —

Please record the burner serial number (and have

available when calling or writing). You will fi nd the

serial number on the silver label located on the left

rear of the burner. Refer to Figure 1.

Inspect/Prepare Installation Site

Clearances to Burner and Appliance

Provide space around burner and appliance for

ease of service and maintenance. Check the mini-

mum clearances against those shown by the ap-

pliance manufacturer and by applicable building

codes.

Inspect Chimney or Direct Vent System

•

•

•

Figure 1. Burner label location

General Information

Inspect the chimney or vent. Make sure it is prop-

erly sized and in good working condition. Follow the

instructions supplied by the appliance manufactur-

er.

The burner cannot properly burn the fuel if it is not

supplied with a reliable combustion air source.

Follow the guidelines in the latest editions of the

NFPA 31 and CSA-B139 regarding providing ad-

equate air for combustion and ventilation.

•

•

Failure to provide adequate air supply could se-

riously affect the burner performance and result

in damage to the equipment, asphyxiation, ex-

plosion or fi re hazards.

Adequate Combustion

and Ventilation Air Supply

Required

WARNING

!