RWB 6104 BNX R02 Page 13

Trained Service Technician’s Regular Maintenance

Figure 7. – Nozzle Line/Head/Air Tube As-

sembly

(Low fi ring rate shown.)

Retention Head

Retention Head

Head Support Legs

Head Support Legs

Electrode Tips

Electrode Tips

Electrode Clamp

Electrode Clamp

Electrode Bracket

Electrode Bracket

Electrode Insulator

Electrode Insulator

Electrode Extension Rods

Electrode Extension Rods

NozzleAdapter

NozzleAdapter

Nozzle

Nozzle

Stops in Retention Ring

Stops in Retention Ring

Retention Ring

Retention Ring

Throttle Ring

Throttle Ring

Throttle Cup

Throttle Cup

Nozzle Line

Nozzle Line

Bulkhead Fitting

Bulkhead Fitting

SK9666A

SK9666A

Throttle Cup Hub

Throttle Cup Hub

SK9666A

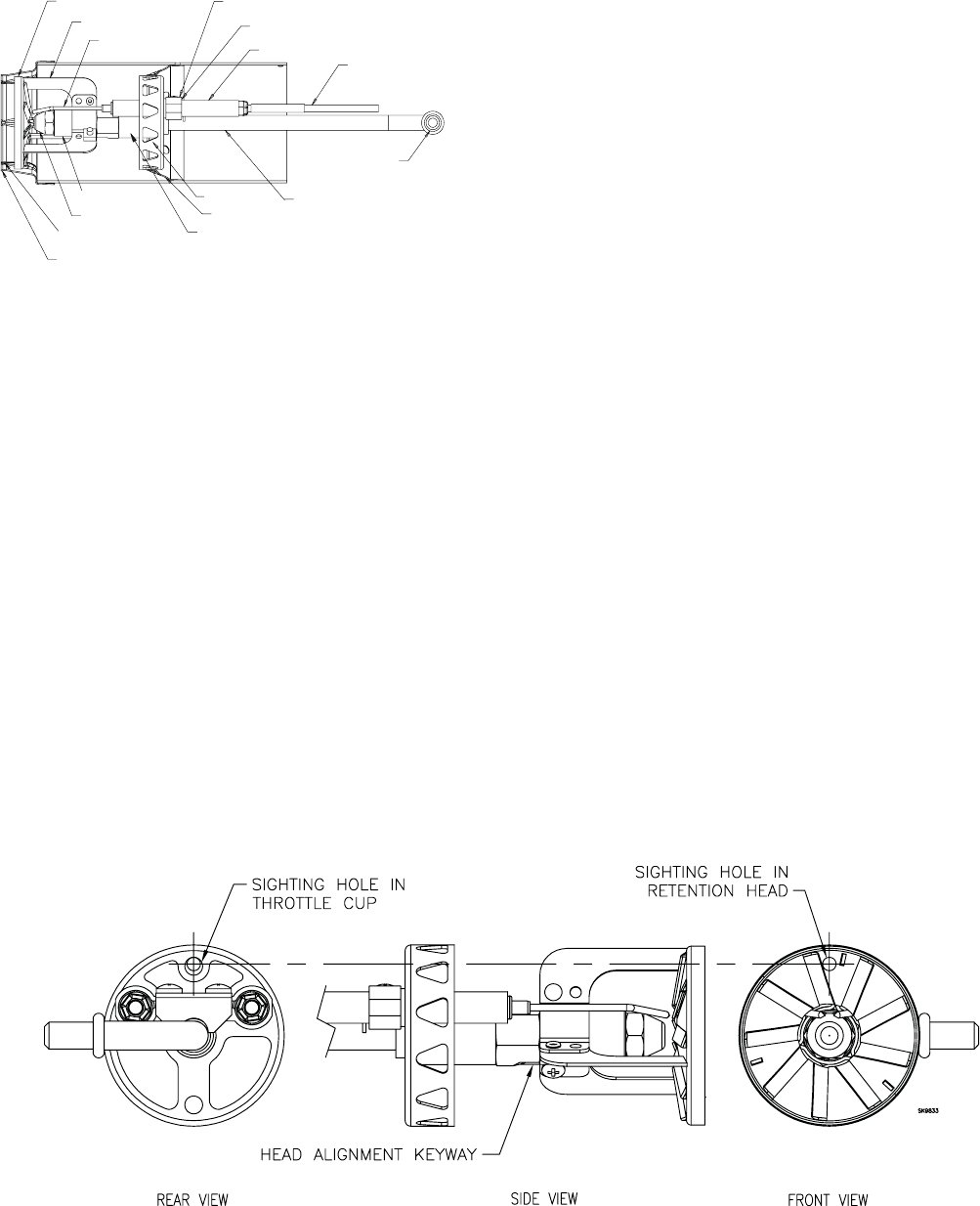

Figure 8 – Retention Head/Throttle Cup Alignment

Check Retention Head Alignment and

Cad Cell Sighting (Refer to Figure 8.)

The cad cell sighting holes in the throttle cup and

the retention head must be aligned to allow the cad

cell to detect the fl ame. Make sure the stamped key

in the retention head collar lines up with the keyway

in the nozzle adapter when mounting the retention

head. Note that in specifi c applications, the reten-

tion head may not have a sighting hole.

Check/Adjust “Zero” Calibration

On burners with factory-installed air tubes, the

zero calibration has been factory set. Make sure

the retention head (Figure 8) is securely against

the stops in the retention ring when the adjustment

plate pointer is at “0” (Figure 5).

•

•

If the zero calibration has not been set, perform the

following procedure:

Install the nozzle line, with the adjustment plate

assembly attached, into the burner.

Install and tighten the rear door to hold the air

adjustment plate assembly in position.

Slightly loosen the upper acorn nut, the splined

nut, and the lower acorn nut.

Turn the air adjustment screw clockwise to adjust

the plate with the pointer to the zero position.

Referring to Figure 8, slide the nozzle line as-

sembly forward until the retention head engages

the fi xed stops in the retention ring at the end of

the air tube.

Tighten the upper acorn nut securely.

The rear door must be kept tightly closed. The

adjustment screw may now be turned to adjust

the head/air setting.

Turn the adjusting screw to a setting that is 1/2

number lower than the proper set point as indi-

cated in Table 1. Then turn the adjusting screw

counterclockwise to the proper setting.

Tighten the splined nut and lower acorn nut after

the head/air setting has been adjusted.

1.

2.

3.

4.

5.

6.

7.

8.

9.

*