7

CG10 Burner Manual

400

500

600

700

800

900

1000

1100

1200

1300

1400

0 0.2 0.4 0.6 0.8 1

Furnace Pressure, In. W.C.

Maximum Capacity, MBH

CG10.6S

CG10.5S

CG10.4S

CG10.3S

CG10.2S

CG10.1S

Verify burner air tube assembly

The information in this section may be disregarded if

the burner supplied by the appliance manufacturer is

a matched component.

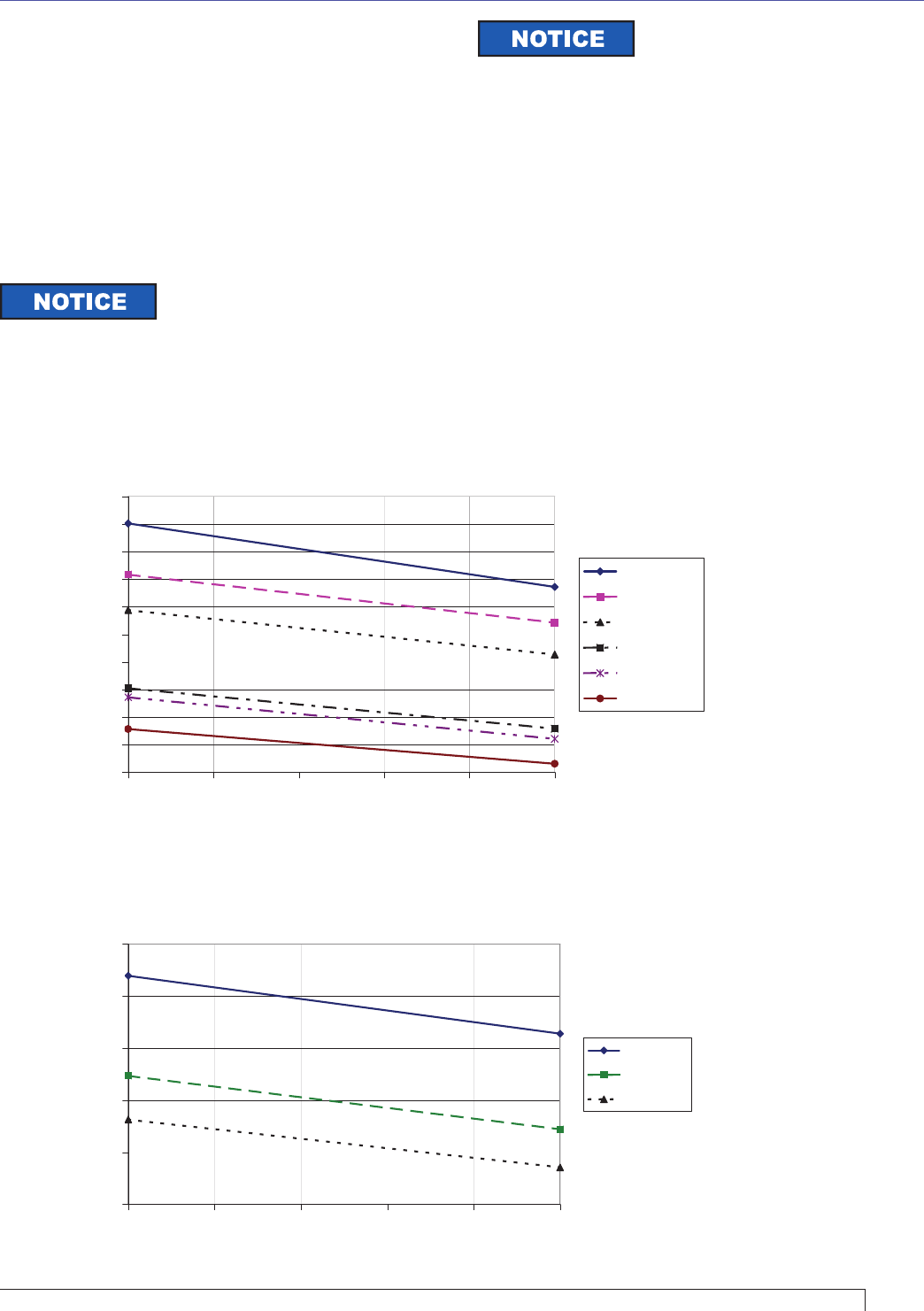

Maximum fi ring capacity depends on the furnace

pressure. Use the charts shown in Figure 3 and

Figure 4, to verify the correct burner confi guration for

the input rate.

Refer to Figure 5 to verify the air tube assembly

length and mounting insertion dimensions.

○

○

○

Figure 3. Maximum Capacity (at 3% O

2

) vs Furnace Pressure - Step Spud Confi guration

Section: Pre-installation Checklist

The volume of the furnace

also infl uences the combustion

process. R. W. Beckett Corp. recommends at least 1

cubic foot of furnace volume for each 150,000 BTU/Hr of

fi ring rate.

Flames are shaped by their

furnaces and by its fl ue locations.

Increased height and width can decrease the length

requirement. When shaping is too severe fl ames

impinge on the walls. Impingement causes CO and

carbon deposits and may damage the wall. Maintaining

these minimum dimensions should prevent impingement,

but smaller furnaces may be acceptable depending

upon the results of applications testing. We recommend

factory testing of all new burner/furnace combinations by

the furnace manufacturer and/or R. W. Beckett Corp.

300

400

500

600

700

800

0 0.2 0.4 0.6 0.8 1

Furnace Pressure, In. WC

Maximum Capacity, MBH

CG10.3

CG10.2

CG10.1

Figure 4. Maximum Capacity (at 3% O

2

) vs Furnace Pressure - Swirler Head Confi guration