10

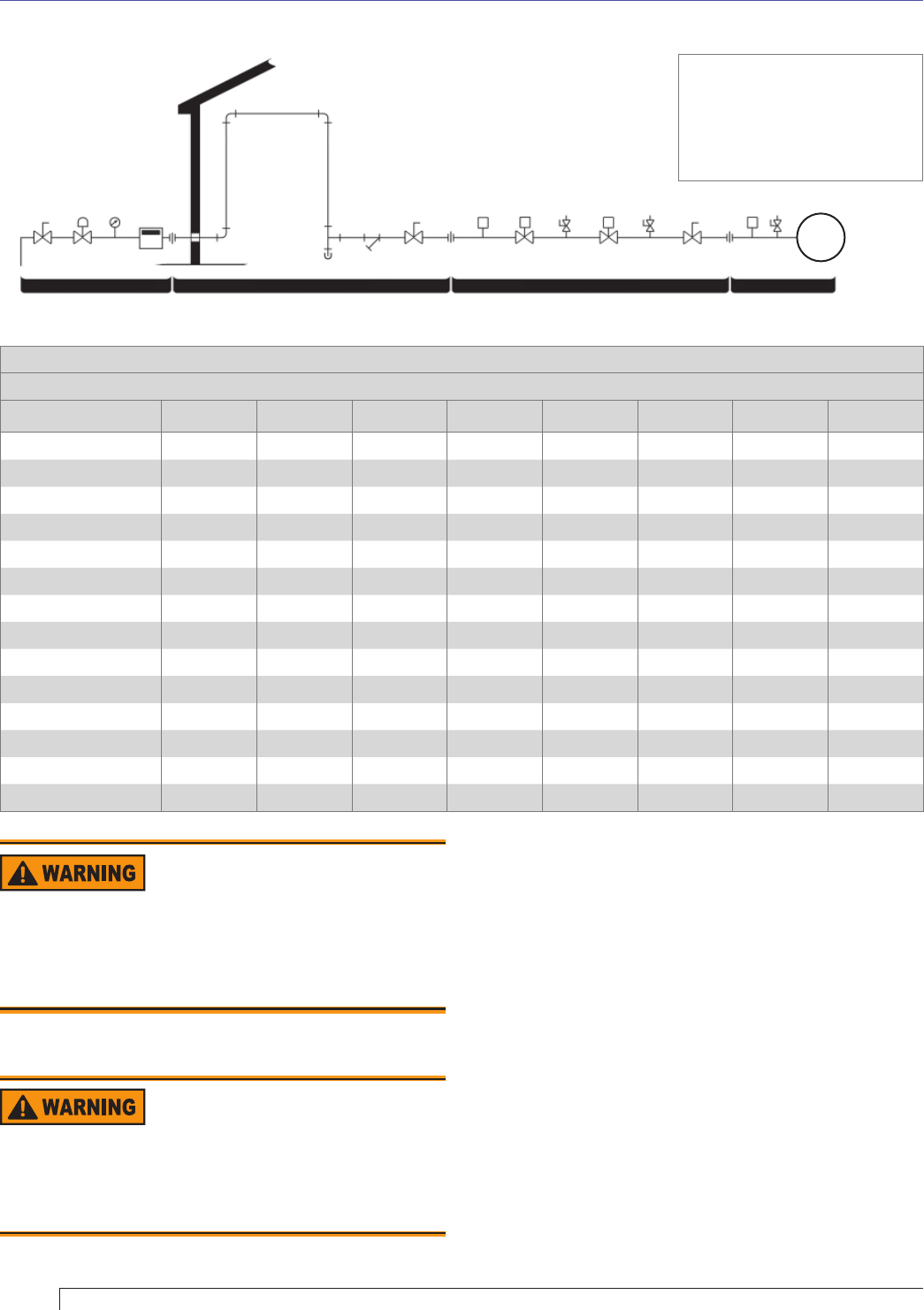

Figure 7. Typical Gas Piping Layout

Schedule 40 metallic pipe with 0.50 psi or less inlet pressure and 0.30” W.C. pressure drop

Maximum capacity in cubic feet of gas per hour (CFH). Natural gas with 0.60 specifi c gravity. Pipe size (inches) IPS

Pipe Length (ft.) 0.75” 1.0” 1.25” 1.5” 2.0” 2.5” 3.0” 4.0”

10 278 520 1050 1600 3050 4800 8500 17500

20 190 350 730 1100 2100 3300 5900 12000

30 152 285 590 800 1650 2700 4700 9700

40 130 245 500 760 1450 2300 4100 8300

50 115 215 440 670 1270 2000 3600 7400

60 105 195 400 610 1150 1850 3250 6800

70 96 180 370 560 1050 1700 3000 6200

80 90 170 350 530 990 1600 2800 5800

90 84 160 320 490 930 1500 2600 5400

100 79 150 305 460 870 1400 2500 5100

125 72 130 275 410 780 1250 2200 4500

150 64 120 250 380 710 1130 2000 4100

175 59 110 225 350 650 1050 1850 3800

200 55 100 210 320 610 980 1700 3500

Table 1. Gas supply piping capacity

Gas Trains

Standard – An Underwriters Laboratories (UL) listed

gas train is standard for the CG10 gas burner. This

confi guration also meets CSD-1 requirements. See

Figure 8 for typical component layout.

Propane (LP) – When the correct propane restrictor

is added to a burner’s gas pipe assembly it changes

the burner’s gas pressure drop so that the propane

pressure drop is equal to the natural gas pressure drop

of the same BTU fi ring rate. That is why the Manifold

to Furnace Pressure Drop curves of Figures 12 and

13 are correct for both propane and natural gas. That

is also why a gas train adjusted for the burner’s natural

gas requirements will be correctly adjusted for its

propane requirements. R. W. Beckett provides the same

pressure regulating safety shutoff valve in the gas train

(usually a Honeywell V4944B) for both natural gas and

propane. The valve is marked for natural gas due to

its primary usage in a pressure range normally used

LGPS

HGPS

S

(IF USED)

DRIP LEG

BURNER

METER

MSC

SSOV1

2PRV

MLTC

U

TC

U

TC

TC

U

PG

REGULATOR

ABBREV.

HGPS

LGPS

MSC

MLTC

PG

S

SSOV1

TC

U

2PRV

ITEM DESCRIPTION

HIGH GAS PRESSURE SWITCH

LOW GAS PRESSURE SWITCH

MAIN SHUTOFF COCK

MAIN LEAK TEST COCK

PRESSURE GAUGE

STRAINER

SAFETY SHUTOFF VALVE #1

TEST COCK

UNION

TWO POSITION REGULATING VALVE

GAS UTILITY PIPING

FACILITY PIPING

GAS TRAIN BURNER

Section: Connect Gas Piping

Install a Drip Leg in Gas

Supply Piping

Foreign matter could lodge in gas valve cutoff seals,

resulting in gas leak-through, explosion or fi re.

Install a full-size drip leg or dirt pocket in the piping directly

ahead of the main shutoff valve to capture foreign matter.

Gas Leaks and Exposion

Hazards

Provide Over-pressure Protection

CSD-1 requires that if gas pressure entering the

building exceeds the rating of any gas train component

an overpressure protection device must be installed.