11

CG10 Burner Manual

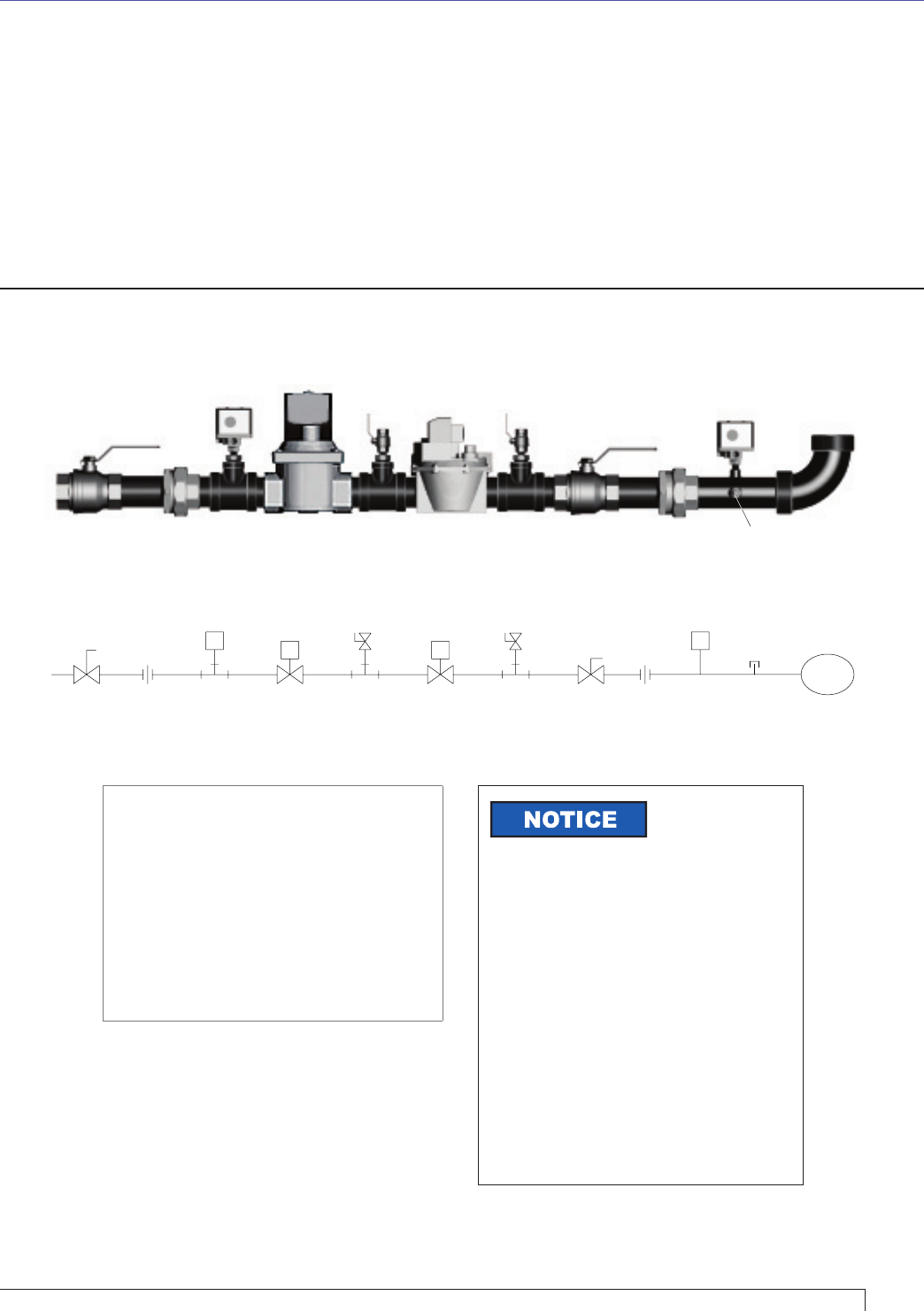

Figure 8. UL gas train confi guration

MSC

U

PRSSOV

SSOV1

MLTC U

BURNER

C6097B

HGPS

TP

C6097A

LGPS

TC

TC

MSC

SSOV1 PRSSOV MLTC

U

U

TP

TC TC

HGPS

LGPS

ABBREV.

HGPS

LGPS

MSC

MLTC

PRSSOV

SSOV1

TC

TP

U

ITEM DESCRIPTION

HIGH GAS PRESSURE SWITCH

LOW GAS PRESSURE SWITCH

MAIN SHUTOFF COCK

MAIN LEAK TEST COCK

PRESSURE REGULATING

SAFETY SHUTOFF VALVE

SAFETY SHUTOFF VALVE #1

TEST COCK

TEST PORT

UNION

Section: Connect Gas Piping

When pressure

reducing safety

shutoff valves are used, the distance

from the fi nal shutoff valve (PRSSOV

in Fig. 8) to the burner manifold must

be kept to a minimum for good light-off

reliability. R.W. Beckett recommends the

following maximum lengths:

Pipe Size

1”

1-1/4”

1-1/2”

2”

Max. Length

12”

15”

18”

24”

If a Normally Open Vent Valve (not

shown) is used, the distance between

the SSOVs must be kept to a minimum

using the shortest practical nipples.

by natural gas appliances. It is safe and effective for

propane usage in this design application.

Optional – Gas trains for IRI and FM are available and

must be specifi ed when ordering a burner.

Verify – Verify that the train components are not

damaged and all piping and fi ttings are clean inside and

out. The gas train is normally shipped as components

and must be assembled and installed at the site.

Vent lines –

Install vent lines to any gas valve component

that requires atmospheric air pressure to balance a

diaphragm. Vent lines must be run to the outdoors, with

the termination point away from fresh air intakes and

windows. The terminal opening must be fi tted with a wire

mesh screen to block insects and other contaminants

from entering the vent and must be mounted in such a

position that water, ice, dirt, or any other foreign matter

cannot infi ltrate and block the vent piping. Make sure the

fi nal assembly is anchored securely.