Page 8 6104 BCF3 R02

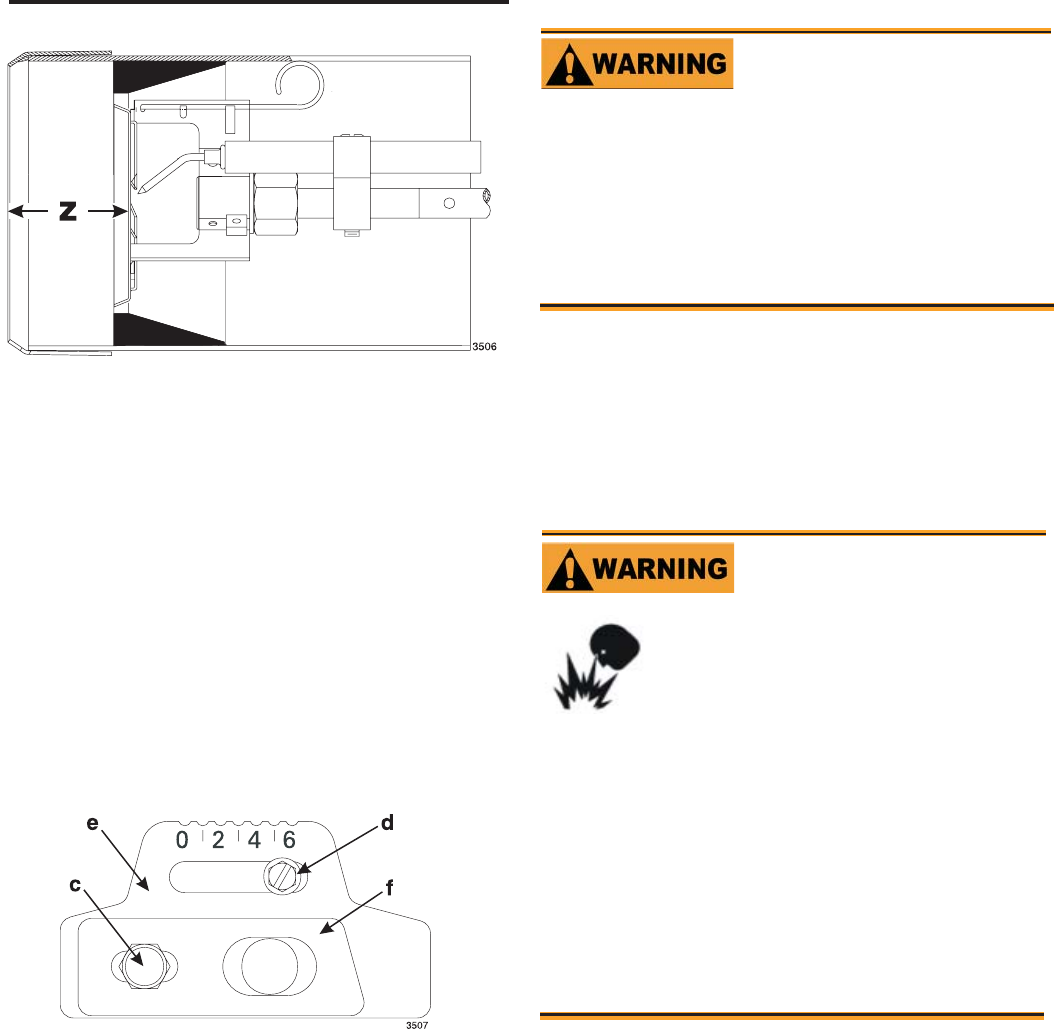

Set dimension Z

Loosen fastener c in Figure 6. Slide the nozzle line and

plate assembly until dimension Z in Figure 5 is 1-1/2”

±1/16”. When dimension Z (from end of air tube to fl at

area of front face of head) is correctly set, tighten acorn

nut c.

Attach the oil line from the oil valve to the nozzle line end.

Tighten securely.

Before proceeding, check dimension Z once again. Loosen

acorn nut c if necessary to reposition the nozzle line. Once

dimension Z is set, do not loosen the acorn nut c again.

Note that for the setting of fastener d, refer to Initial Head

Position procedure on Page 10.

y

y

y

Figure 6 - Adjusting plate assy.

Legend (Figures 5 and 6)

c

Bottom acorn nut

d

Fastener

The burner is shipped without the by-pass plug in-

stalled.

Intall the by-pass plug in two-pipe oil supply systems

ONLY.

y

y

Failure to comply could cause immediate pump

seal failure, pressurized oil leakage and the po-

tential for a fi re and injury hazard.

Do Not Install By-pass

Plug with 1-Pipe System

e

Indicator adjusting plate

f

Secondary adjusting plate

Install the oil tank and oil lines in accordance with all

applicable state and local codes.

Size the oil supply and return lines using the guidelines

given in the fuel unit literature included in the literature

envelope. Oil line fl ow rate will equal the burner rate for

one-pipe systems. For two-pipe systems, refer to Table 2

for the fuel unit gear set capacity - the rate at which fuel

is recirculated when connected to a two-pipe system. Size

two-pipe oil lines based on this fl ow rate.

Use continuous lengths of heavy-wall copper tubing,

routed under the fl oor where possible. Do not attach fuel

lines to the appliance or to fl oor joists if possible. This will

reduce vibration and noise transmission problems.

Install an oil fi lter sized to handle the fuel unit gearset fl ow

capacity (Table 2) for two-pipe systems. Size the fi lter

for the fi ring rate for one-pipe systems. Locate the fi lter

immediately adjacent to the burner fuel unit.

y

y

y

y

Carefully install the oil supply lines, fi ttings and com-

ponents using the guidelines provided in this section.

The oil supply must comply with the latest edition

of NFPA 31 (Canada CSA B139) and all applicable

codes.

Do NOT install valves in return lines.

If the oil supply inlet pressure to the pump exceeds 3

psig or for gravity feed systems, install an oil safety or

pressure reducing valve (Webster OSV, Suntec PRV or

equivalent).

y

y

y

y

Failure to properly install the oil

supply system could cause oil

leakage, equipment malfunction,

puff-back of hot gases, heavy

smoke, asphyxiation, explosion and

fi re hazards.

Install Oil Supply To

Specifi cations

Fuel unit by-pass plug

Figure 5 - Nozzle line assembly in burner

1-1/2”

Insert burner

Position the burner in the front of the appliance and loosely

tighten the nuts on the mounting studs. The burner should

be pitched downward 2° as shown in Figure 3.

Secure the burner to the appliance by tightening the nuts

on the burner fl ange mounting studs.

y

y

The CF375 burner is shipped without the by-pass plug

installed in the fuel line.

The by-pass plug must NOT be installed when using

with a one-pipe oil system.

The by-pass plug MUST be installed when using a

two-pipe oil system

.

Oil supply/return lines

y

y

y