16

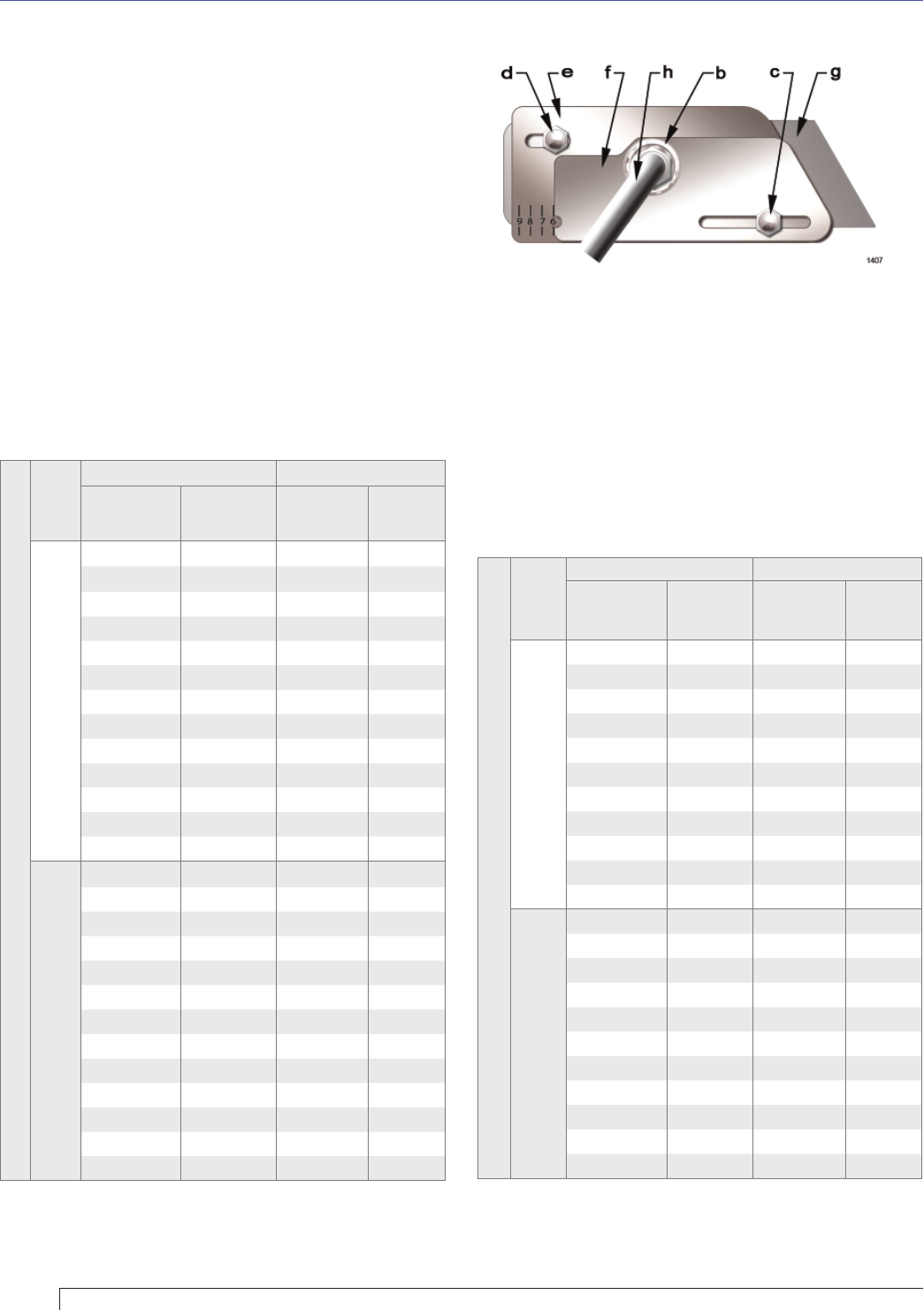

Figure 16 – Adjusting Plate Initial Setting, Typical

Table 4A – CF1400 Initial Indicator Adjustment Plate

Settings

CF1400

Tube

Head Position Damper Position

Approximate

Head Setting

Firing Rate

(gph)

Approximate

Air Damper

Setting

Firing

Rate (gph)

A

0 4.00 0 --

1 4.50 10 --

2 5.00 20 4.00

3 6.00 30 5.00

4 7.00 40 7.00

5 7.50 50 8.00

6 8.00 60 10.00

7 9.00 70 11.00

8 9.50 80 --

9 10.00 90 --

10 11.00 100 --

-- -- 110 --

-- -- 120 --

B

0 7.00 0 --

1 7.50 10 --

2 8.00 20 --

3 9.00 30 --

4 10.00 40 7.00

5 10.50 50 8.00

6 11.00 60 10.00

7 12.00 70 11.00

8 13.00 80 12.00

9 13.25 90 12.50

10 13.60 100 13.00

-- -- 110 13.25

-- -- 120 13.60

Table 4B – CF2300 Initial Indicator Adjustment Plate

Settings

CF2300

Tube

Head Position Damper Position

Approximate

Head Setting

Firing Rate

(gph)

Approximate

Air Damper

Setting

Firing

Rate (gph)

A

011.00--

1 12.0 10 7.0

2 13.0 20 10.0

3 14.0 30 13.0

4 15.0 40 14.0

5 16.0 50 15.0

6 17.0 60 16.0

7 18.0 70 17.0

8 19.0 80 18.0

9 20.0 90 19.0

-- -- 100 20.0

B

0 12.5 0 --

1 13.0 10 10.0

2 14.0 20 13.0

3 15.0 30 14.0

4 16.0 40 15.0

5 17.0 50 16.0

6 18.0 60 17.0

7 18.5 70 18.0

8 19.0 80 18.5

9 20.0 90 19.0

-- -- 100 20.0

Legend

b Spline nut for securing nozzle line

c Bottom acorn nut (for head adjustments)

d Top acorn nut (for setting dim. Z only - do not loosen

after setting Z)

e Indicator adjusting plate

f Secondary adjusting plate

g Primary adjusting plate

h Copper oil line from oil valve to nozzle line

Initial Head Position

The indicator plate assembly (item e) markings

correspond to head position settings (Figure 16).

Slide the secondary adjusting plate (item f) toward

the rear of the burner until the number on the

indicator plate corresponds to the initial head setting

given in

Tables 4a and 4b for the desired fi ring rate

and burner (high-fi re).

Figure 16 shows a typical example, with a head

setting of 6.

When the head position has been set, tighten the

bottom acorn nut (item c) and the spline nut (item b).

○

○

○

Section: Prepare the Burner for Start-up