10

Special Note: The burner is shipped with a by-

pass plug installed in the fuel unit. For low/high

operation, the by-pass plug must be left in the fuel

unit, regardless of the fuel system used (one-pipe

with by-pass loop or two-pipe). Do not remove the

by-pass plug.

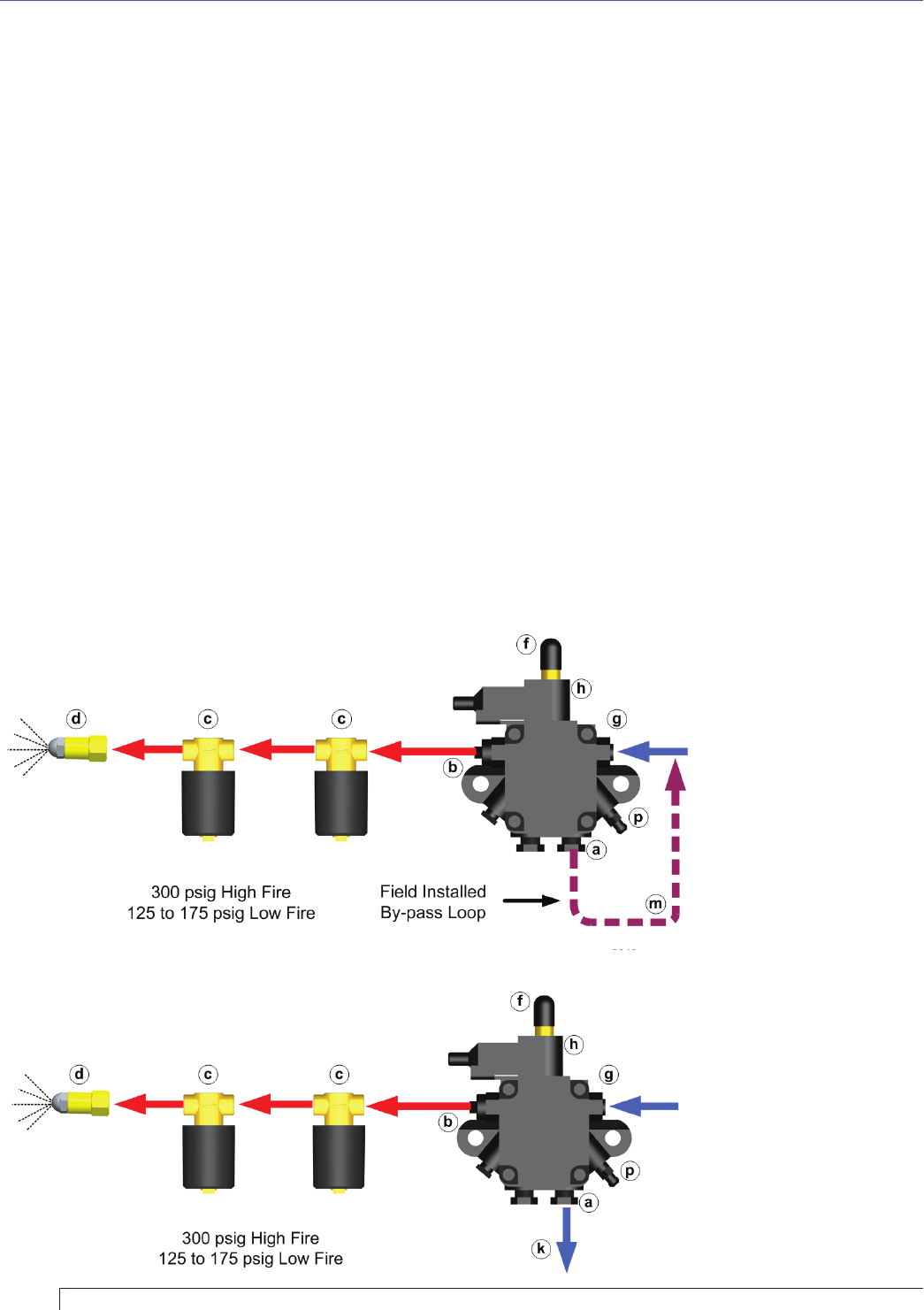

One-pipe Oil System By-pass Loop

Refer to Figure 9 (item m). Note the addition of a fi eld-

installed by-pass loop (use 3/8” copper tubing) from the

fuel unit Return port to the Inlet port. This line is required

for low/high operation. It simulates the fl ow of a two-pipe

system at the fuel unit.

Oil Supply/Return Lines

Install the oil tank and oil lines in accordance with all

applicable codes.

Size the oil supply and return lines using the

guidelines given in the fuel unit literature included in

the literature envelope. Oil line fl ow rate will equal

the burner rate for one-pipe systems. For two-pipe

systems, refer to Table 3 for the fuel unit gearset

capacity - the rate at which fuel is recirculated when

connected to a two-pipe system. Size two-pipe oil

lines based on this fl ow rate.

○

○

Legend (Figure 9 & 10)

a Return port

b Nozzle port

c Oil valves

d Nozzle & adapter

f

By-pass/Low fi re pressure

regulator

g Inlet port

h By-pass valve (“B” pump)

k Return line to oil tank

m One-pipe by-pass loop, 3/8”

p Air bleed valve

Figure 9 – One-pipe Oil Flow with “B” Pump

SK9940

Figure 10 – Two-pipe Oil Flow with “B” Pump

SK9939

Use continuous lengths of heavy-wall copper tubing,

routed under the fl oor where possible. Do not attach

fuel lines to the appliance or to fl oor joists if possible.

This reduces vibration and noise transmission

problems.

Install an oil fi lter sized to handle the fuel unit

gearset fl ow capacity (Table 3) for two-pipe systems.

However, size the fi lter for the fi ring rate for one-pipe

systems. Locate the fi lter immediately adjacent to

the burner fuel unit.

Install two high-quality shutoff valves in accessible

locations on the oil supply line. Locate one valve

close to the tank. Locate the other valve close to the

burner, upstream of the fuel fi lter.

Burner Fuel Flow

One-pipe systems – See Figure 9 for the fuel fl ow

paths for high-fi re and low-fi re operation. The low-fi re

by-pass regulation is done internally for type B fuel units.

Oil supply connects to one of the fuel unit Inlet ports.

Two-pipe systems – See Figure 10 for the fuel fl ow

paths for high-fi re and low-fi re operation. The low-fi re

by-pass regulation is done internally for type B fuel units.

Oil supply connects to one of the fuel unit Inlet ports.

Oil return connects to the fuel unit Return port. Do NOT

install valves in the return line.

○

○

○

Section: Mount the Burner