6

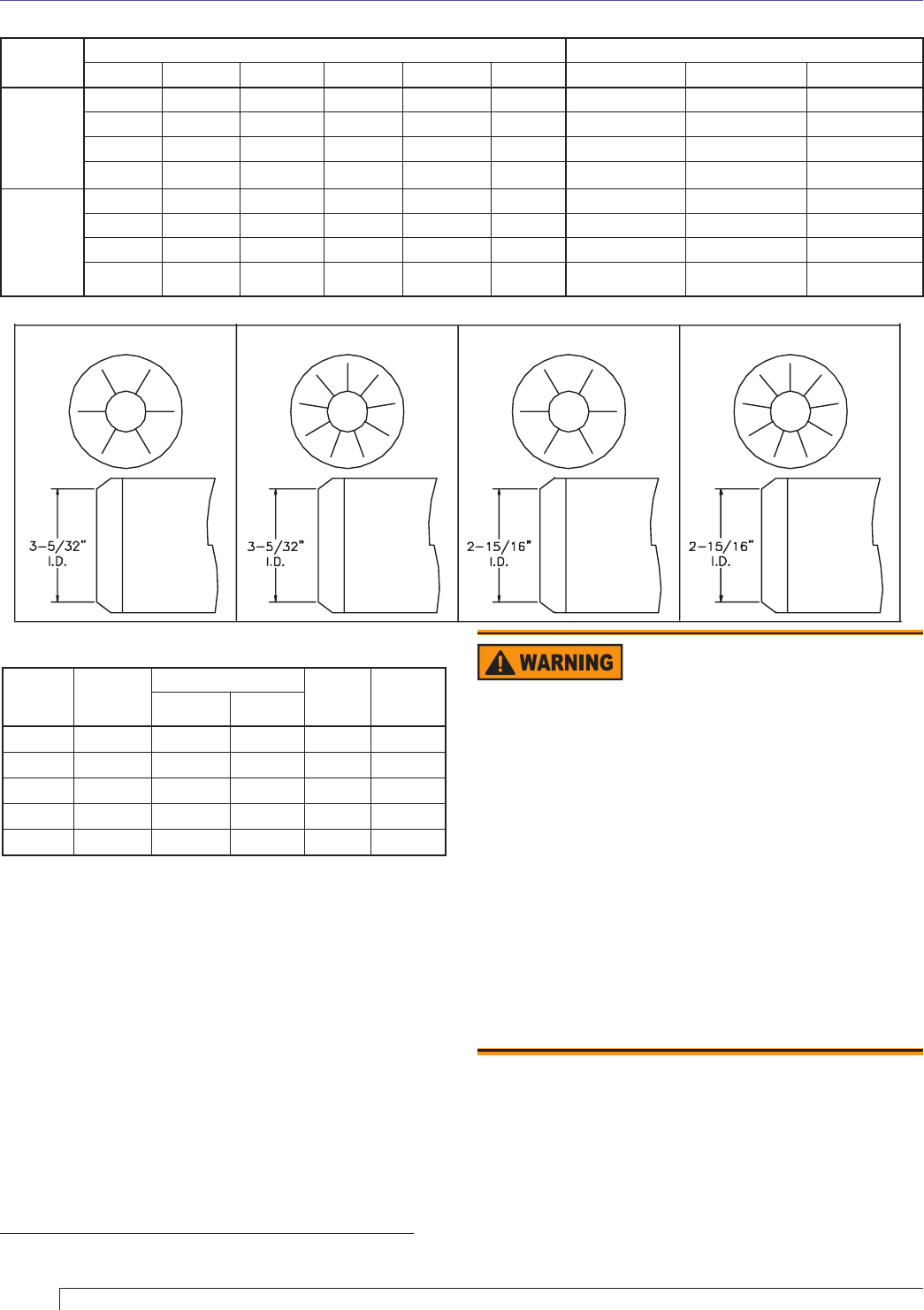

HB 6 slot

HC 9 slot

HD 6 slot

HE 9 slot

Any accumulation of soot or debris in chimney

offsets should be removed

Any obstructions such as a protruding joint or a

piece of broken tile wedged in the chimney should

be removed.

No other appliance connection should be made to

the same fl ue pipe.

The fl ue pipe should have an upward pitch toward

the chimney of at least 1/4” per foot of length. It

should fi t tightly and should not project into the

chimney.

Any leakage between tiles, around clean-out doors,

or around the vent pipe should be sealed.

INSULATED STAINLESS STEEL CHIMNEY LINERS

3.

4.

5.

6.

7.

The new designs of high effi ciency oil furnaces and

boilers in conjunction with fl ame retention oil burners

are more effi cient. One result of increased effi ciency is

lower fl ue gas temperatures. As fl ue gases rise in the

chimney, they will cool and condense when they reach

the dew point. The condensation will mix with the sulphur

in the fl ue gases creating sulphuric acid. The acid will

attack the chimney mortar, brick and clay liners causing

corrosion, deterioration and blockage of the chimney.

Table 2 – Air Tube Combinations (ATC) & Dimensions

ATC codes for usable air tube lengths dim. “A” (Figure 3) Firing rate range (gph)Min-Max

3” 5” 7” 9” ATC Code Head AFII 85 AFII 100 AFII 150

Adjustable

w/stop screw

Head Design

HLX30 HLX50 HLX70 HLX90 HB AF2-6 0.4-0.85 gph 0.65-1.00 gph 0.75-1.35 gph

HLX30 HLX50 HLX70 HLX90 HC AF2-9 N/A 0.65-1.00 gph 0.75-1.50 gph

HLX30 HLX50 HLX70 HLX90 HD AF2-6 0.40-0.85 gph 0.65-1.00 gph 0.75-1.10 gph

HLX30 HLX50 HLX70 HLX90 HE AF2-9 N/A 0.65-1.00 gph 0.75-1.35 gph

Head Design

- Fixed

FBX30 FBX50 FBX70 FBX90 HFXS FB0 0.40-0.65 gph 0.55-0.75 gph 0.75-1.00 gph

FBX30 FBX50 FBX70 FBX90 HGXS FB3 0.55-0.85 gph 0.55-1.10 gph 0.85-1.20 gph

FBX30 FBX50 FBX70 FBX90 HHXS FB4 N/A 0.75-1.10 gph 1.10-1.25 gph

FBX30 FBX50 FBX70 FBX90 HIXS FB6 N/A 0.85-1.15 gph 1.15-1.35 gph

Table 3 – Minimum Combustion Chamber Dimensions (inches)

Firing

Rate

(gph)

Round

I.D.

Rectangular

Height

Floor to

nozzle

Width Length

0.50 8 7 8 12 5 to 6

0.75 9 8 9 12 5 to 6

1.00 10 9 10 12-1/2 5 to 6

1.25 11 10 11 12-1/2 5 to 6

1.50 12 11 12 13 6 to 7

Section: Inspect/Prepare Installation Site

Carefully inspect the chimney or exhaust vent

system.

Make sure it is properly sized and in good working

condition.

Follow the instructions supplied by the appliance

manufacturer.

The installation must strictly comply with all

applicable codes, authorities having jurisdiction and

the latest revision of the National Fire Protection

Association Standard NFPA 31 for the installation of

chimneys and vent sizing, (or CSA-B139 and CSA-

B140 in Canada).

Regulation by these authorities take precedence

over the general instructions provided in this

installation manual.

y

y

y

y

y

Fire, Smoke & Asphyxiation

Hazard