16

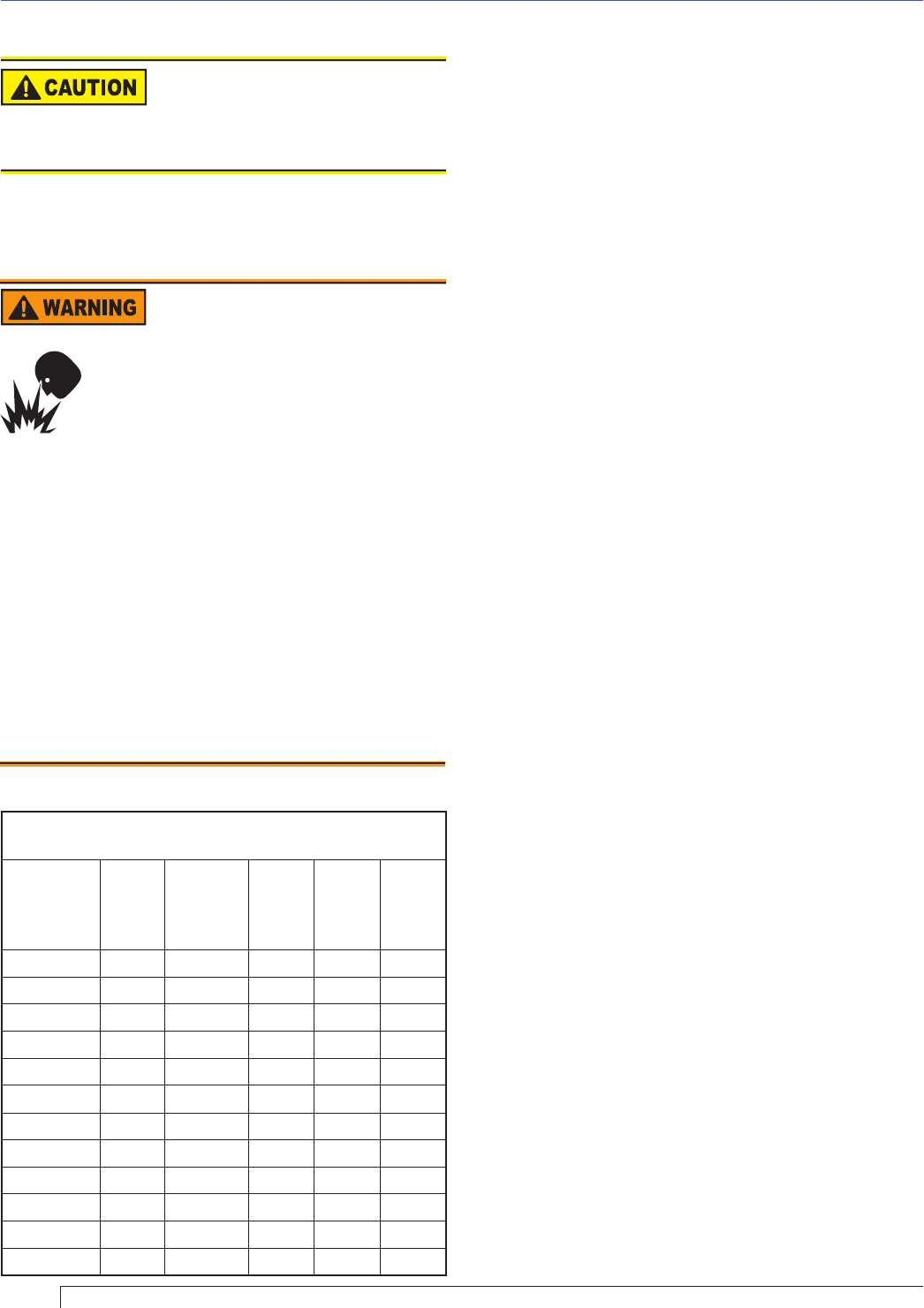

Table 4 - Nozzle Flow Rate by Size

Nozzle fl ow rate U. S. gallons per hour of No. 2 fuel oil

when pump pressure (psig) is:

Nozzle

size (rated

at 100

psig)

125

psi

140 psi

(factory

std.)

150

psi

175

psi

200

psi

0.40 0.45 0.47 0.49 0.53 0.56

0.50 0.56 0.59 0.61 0.66 0.71

0.60 0.67 0.71 0.74 0.79 0.85

0.65 0.73 0.77 0.80 0.86 0.92

0.75 0.84 0.89 0.92 0.99 1.06

0.85 0.95 1.01 1.04 1.13 1.20

0.90 1.01 1.07 1.10 1.19 1.27

1.00 1.12 1.18 1.23 1.32 1.41

1.10 1.23 1.30 1.35 1.46 1.56

1.20 1.34 1.42 1.47 1.59 1.70

1.25 1.39 1.48 1.53 - -

1.35 1.51 - - - -

Shutting the Burner Off

Always keep the fuel oil

supply valve shut off if the

burner(s) is shut down for an extended

period of time.

Turn off all electric power to the burner. Note: There

could be more than one disconnect switch.

Removing Nozzle Line for Service

Correct Nozzle and Flow

Rate Required

Incorrect nozzles and fl ow rates could

result in impaired combustion, under-

fi ring, over-fi ring, sooting, puff-back of

hot gases, smoke and potential fi re or

asphyxiation hazards.

Use only nozzles having the brand, fl ow rate (gph), spray

angle and pattern specifi ed by the appliance manufacturer.

Follow the appliance manufacturer’s specifi cations for

the required pump outlet pressure for the nozzle, since

this affects the fl ow rate.

Nozzle manufacturers calibrate nozzle fl ow rates at

100 psig.

When pump pressures are higher than 100 psig, the

actual nozzle fl ow rate will be greater than the gph

stamped on the nozzle body. (Example: A 1.00 gph

nozzle at 140 psig = 1.18 gph)

Securely tighten the nozzle (90 torque inch pounds). For

typical nozzle fl ow rates at various pressures refer to Table 5.

y

y

Turn off power to burner before proceeding.

Disconnect copper oil connector tube from nozzle

line.

Loosen the screw that fastens the rear access door.

Remove splined nut.

Remove the nozzle line assembly from the burner,

being careful not to damage the electrodes or

insulators while handling. Stop halfway to remove

igniter/transformer wires.

To replace the nozzle assembly, reverse the

above steps. “HLX” head air tubes – Be sure stop

screw is fastened securely. Seat stop screw on

back of choke ring to set the position of the head.

“FBX” head air tubes – Use T gauge to set the “Z”

dimension to 1-

1/8” +/- 1/32”

Nozzle Installation

Perform the following steps when replacing a nozzle.

Remove the nozzle line assembly to gain access to

the nozzle.

Use a 3/4” open-end wrench to hold the nozzle

adapter. DO NOT attempt to remove or replace

the nozzle without securing the adapter, as nozzle

alignment could be seriously affected.

Do not squeeze the electrodes when handling the

nozzle line assembly. Excessive force could change

the electrode tip settings or damage the ceramic

electrode insulators.

Use a 5/8” open-end wrench to carefully remove the

existing nozzle.

Inspect the nozzle adapter before installing the

new nozzle. If it is grooved or scratched on the

sealing surface, replace the nozzle line assembly.

If the surface is damaged, oil could leak at the

nozzle to adapter joint, causing serious combustion

problems.

Protect the nozzle orifi ce and strainer when

installing. If the orifi ce gets dirt in it or is scratched,

the nozzle will not function properly.

To install a new nozzle, place a 3/4” open-end

wrench on the nozzle adapter. Insert the nozzle

into the adapter and secure fi nger tight. Finish

tightening with a 3/8” open-end wrench. Use care

to avoid bending the burner head support legs or

electrodes.

Do not over-torque the nozzle when installing. This

will cause deep grooves in the nozzle adapter,

preventing a seal when a new nozzle is installed.

Carefully check and realign the electrode tips after

replacing a nozzle, ensuring the electrode settings

comply with Figure 11a or 11b.

1.

2.

3.

4.

5.

6.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Section: Perform Regular Maintenance