15

AFII Burner Manual

Perform Regular Maintenenance

The following guidelines are provided for routine

maintenance.

Replace the oil supply line fi lter. The line fi lter

cartridge must be replaced to avoid contamination

of the fuel unit and nozzle.

Inspect the oil supply system. All fi ttings should be

leak-tight. The supply lines should be free of water,

sludge and other restrictions.

Remove and clean the pump strainer if applicable.

Replace the nozzle with an exact replacement as

specifi ed by the appliance manufacturer.

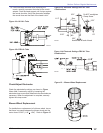

Clean and inspect the electrodes for damage,

replacing any that are cracked or chipped.

Check electrode tip settings. Replace electrodes if

tips are rounded.

Inspect the igniter cables and connections.

Clean the cad cell grid surface, if necessary.

Inspect all gaskets. Replace any that are damaged

or would fail to seal adequately.

Inspect the combustion head and air tube. Remove

any carbon or foreign matter. Replace all damaged

units with exact parts.

Clean the blower wheel, air inlet, air guide, burner

housing and nozzle line assembly of any lint or

foreign material.

If motor is not permanently lubricated, oil motor with

a few drops of SAE 20 nondetergent oil at each oil

hole. DO NOT over oil motor. Excessive oiling can

cause motor failure.

Check motor current. The amp draw should not

exceed the nameplate rating.

Check all wiring for secure connections or insulation

breaks.

Check the pump pressure and cutoff function.

Check primary control safety lockout timing.

Check ignition system for proper operation.

Inspect the vent system and chimney for soot

accumulation or other restriction.

Clean all fl ue passages and fl ue pipe. Replace

corroded or damaged pipes.

Clean the appliance thoroughly according to the

manufacturer’s recommendations.

Check the burner performance. Refer to the section

“Set combustion with test instruments”.

It is good practice to make a record of the service

performed and the combustion test results.

□

□

□

□

□

□

□

□

□

□

□

□

□

□

□

□

□

□

□

□

□

□

Natural Draft Applications; typically over-fi re draft

is -0.01” or -0.02” w.c.

Direct Venting; typically may not require draft

adjustment.

High Effi ciency/Positive Pressure Appliances;

also vary from traditional appliances (see

manufacturer’s recommendations).

Follow these four steps to properly adjust the burner:

Step 1: Adjust the air dial until a trace of smoke is

achieved.

Step 2: At the trace of smoke level, measure the

CO

2

(or O

2

) . This is the vital reference

point for further adjustments. Example:

13.5% CO

2

(2.6% O

2

)

Step 3: Increase the air to reduce the CO

2

by

1.5 to 2 percentage points. (O

2

will be

increased by approximately 2.0 to 2.7

percentage points.) Example: Reduce

CO

2

from 13.5% to 11.5% (2.6% to 5.3%

O

2

).

Step 4: Recheck smoke level. It should be Zero.

This procedure provides a margin of

reserve air to accommodate variable

conditions.

If the draft level has changed, recheck

the smoke and CO

2

levels and readjust

the burner if necessary

Once combustion is set, tighten all fasteners on air

dial, rear access door, and escutcheon plate.

Start and stop the burner several times to ensure

satisfactory operation. Test the primary control

and all other appliance safety controls to verify

that they function according to the manufacturer’s

specifi cations.

○

○

○

3.

○

○

4.

5.

Annual Professional

Service Required

Tampering with or making incorrect

adjustments could lead to equipment

malfunction and result in asphyxiation,

explosion or fi re.

DO NOT TAMPER WITH THE UNIT OR

CONTROLS - CALL YOUR SERVICE PERSONNEL.

To ensure continued reliable operation, a qualifi ed

service technician must service this burner annually.

More frequent service intervals may be required in

dusty or adverse environments.

Operation and adjustment of the burner requires

technical training and skillful use of combustion test

instruments and other test equipment.

y

y

y

Section: Perform Regular Maintenance