Page 10 RWB 6104 BAFG R02

The burner may be equipped with a single-stage

fuel unit for these installations. Connect the fuel

supply to the burner with a single supply line if you

want a one-pipe system (making sure the bypass

plug is NOT installed in the fuel unit.) Manual bleed-

ing of the fuel unit is required on initial start-up. If

connecting a two-pipe fuel supply, install the fuel

unit bypass plug.

Servicing nozzle line assembly

Turn off power to burner before proceeding.

Disconnect oil connector tube from nozzle line.

Loosen the two screws securing igniter retain-

ing clips and rotate both clips to release igniter

baseplate. Then tilt igniter back on its hinge.

Remove splined nut.

“F” head air tube. - Remove nozzle line assem-

bly from burner, being careful not to damage the

electrodes or insulators while handling. To ease

removal of long assemblies (over 9 inches), ro-

tate assembly 180° from installed position after

pulling partially out of tube.

“L1”, “L2”, and “V1” head air tubes. - S l i d e

nozzle line assembly forward (further into air

tube) so the head clears the venturi opening.

Then rotate the nozzle line assembly 90° so the

nozzle line end points up. Pull the nozzle line

assembly toward you and remove assembly

from burner.

To replace the nozzle assembly, reverse the

above steps.

Mount burner on appliance

Mounting options

Bolt the burner to the appliance using the fac-

tory-mounted fl ange or an adjustable fl ange.

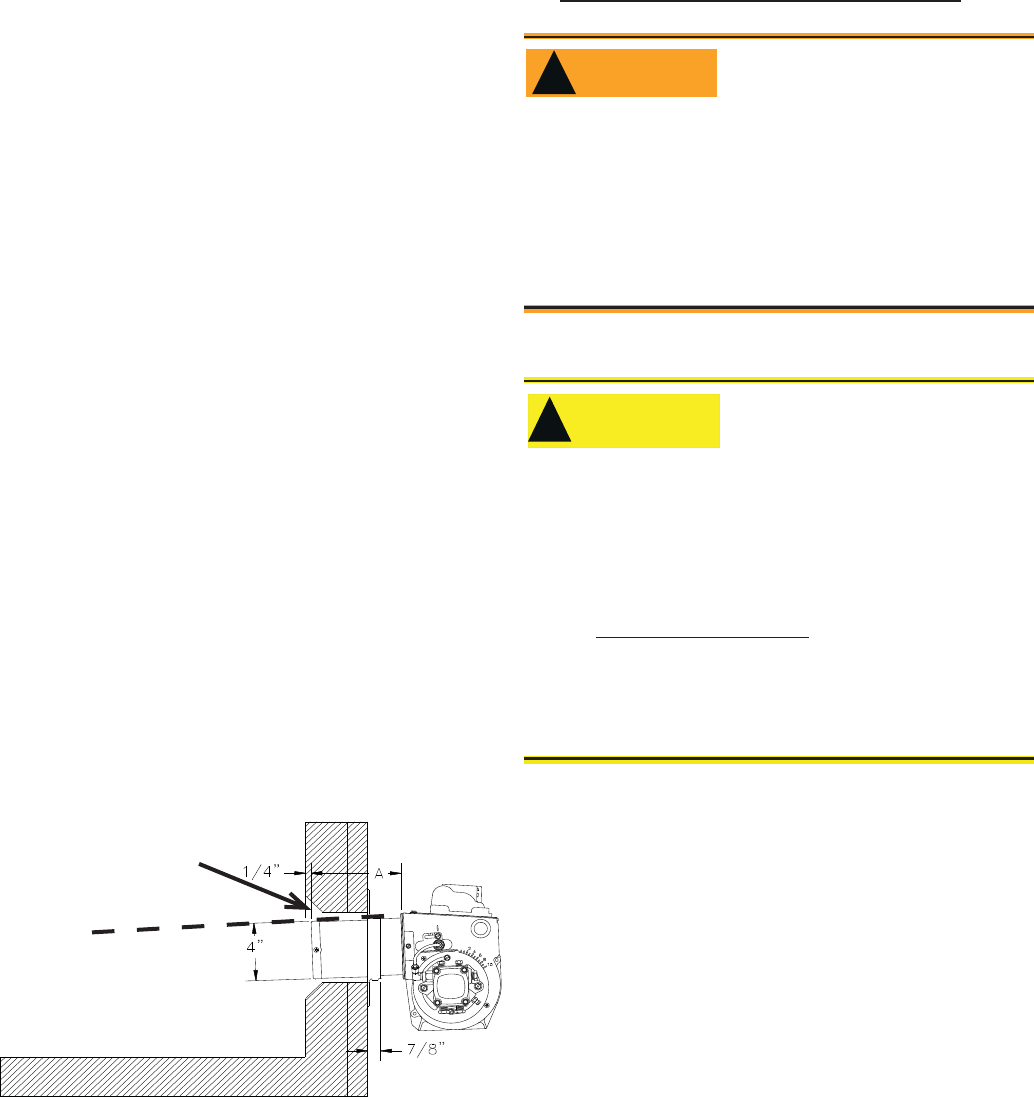

Mounting dimensions

When using the Beckett universal adjustable

fl ange, mount the air tube at a 2° downward

pitch unless otherwise specifi ed by the appli-

ance manufacturer.

Verify that the air tube installed on the burner

provides the correct insertion depth. See Fig-

ure 6.

The end of the air tube should normally be ¼”

back from the inside wall of the combustion

chamber. Never allow the leading edge of the

head assembly to extend into the chamber, un-

1.

2.

3.

4.

5.

6.

7.

1.

1.

2.

3.

The burner is shipped without the by-pass plug

installed.

Install the by-pass plug in two-pipe oil supply sys-

tems ONLY.

y

y

Failure to comply could cause Immediate pump

seal failure, pressurized oil leakage and the po-

tential for a fi re and injury hazard.

WARNING

!

Do Not Install By-pass Plug

with 1-Pipe System

less otherwise specifi ed by the heating appli-

ance manufacturer. Carefully measure the in-

sertion depth when using an adjustable fl ange.

Verify the insertion depth when using a welded

fl ange.

Connect fuel lines

Carefully follow the fuel unit manufacturer’s litera-

ture and the latest edition of NFPA 31 for oil supply

system specifi cations.

Fuel supply level with or above burner –

SK8745

Figure 6. – Mounting Burner in Appliance

Tilt down 2

o

If space between burner

air tube and opening

exceeds 1/2 inch, pack

burner opening with ce-

ramic fiber refractory.

The oil supply inlet pressure to the burner cannot

exceed 3 psig.

Insure that a pressure limiting device is installed

in accordance with the latest edition of NFPA 31.

Gravity Feed Systems: Always install an anit-

siphon valve in the oil supply line or a solenoid

valve (RWB Part # 2182602U) in the pump/noz-

zle discharge tubing to provide backup oil fl ow

cut-off protection.

y

y

y

Damage to the fi lter or pump seals could cause

oil leakage and a fi re hazard.

Oil Supply Pressure

Control Required

!

!

CAUTION