Manual 2100-422M

Page 30 of 42

LOUVERS AND GRILLES

In calculating free area for ventilation and combustion

air requirements, consideration shall be given to the

blocking effect of louvers, grilles, or screens protecting

openings. Screens used shall not be smaller than 1/4

inch (6.3 mm) mesh and shall be readily accessible for

cleaning. If the free area through a design of louver or

grille is known, it shall be used in calculating the size

opening required to provide the free area specified. If

the design and free area is not known, it may be

assumed that wood louvers will have 30-35 percent free

area and metal louvers and grilles will have 60-75

percent free area.

VENTING OPTIONS

This furnace is designed to be vented conventionally

into a vertical chimney or horizontally through a side

wall with an optional Field Controls side wall power

venting system.

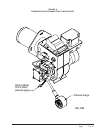

Note that the FH, FC and FLF series furnaces have

been designed to allow for bringing the vent system

through the cabinet side for increased venting

flexibility. To take advantage of this feature, simply

remove the desired knockout from either side or top of

unit and rotate flue box accordingly by removing four

(4) screws under cleanout plate as shown in Figure 4.

Make sure smoke pipe gasket is in place before

reinstalling flue box screws.

VERTICAL VENTING

If the unit is to be vertically vented make sure the flue

pipe from the furnace to the chimney is the same size

diameter as the flue outlet of the furnace which is 6".

The flue pipe must have no reductions in diameter, be

made of a corrosion-resistant material having an

upward pitch of 1/4" for every foot of horizontal run,

and be made of material capable of handling

temperatures up to 1800° F.

A barometric damper is supplied with the furnace and

must be installed in the flue pipe observing the

instructions packaged with the damper control. The

barometric damper opening must be located in the same

atmospheric pressure zone as the combustion air inlet to

the furnace. The furnace must not be vented into the

same chimney with any solid fuel burning appliance

such as a wood burner or pellet burner. Masonry

chimneys must be lined with a listed system or other

approved material that will resist corrosion, softening

or cracking from flue gas temperatures up to 1800° F.

See Standard for Installation of Oil Burning Equipment

NFPA31 latest edition and Standard for Chimneys

NFPA211 latest edition for additional information.

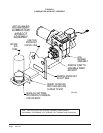

HORIZONTAL VENTING

This furnace is designed to be horizontally vented

through a side wall with an optional side wall power

vent. The recommended side wall venter is the Field

Controls model number SWG-4HDS for 085 and 110

models, and SWG-5S for 140 models only. This venter

can be purchased through your local distributor.

Follow all installation instructions packaged with the

venter system.

THERMOSTAT

These furnaces are designed to be controlled with any

24V heating or heating/cooling thermostat. The

heat/cool thermostats must be designed for independent

heat/cool transformer circuits to assure that the 24V

transformer built into the oil primary control does not

conflict with the main furnace 24V transformer. The

heat anticipator should be set at 0.20A. This is a

nominal setting. The thermostat circuit should be

checked to verify setting.