Manual 2100-422M

Page 25 of 42

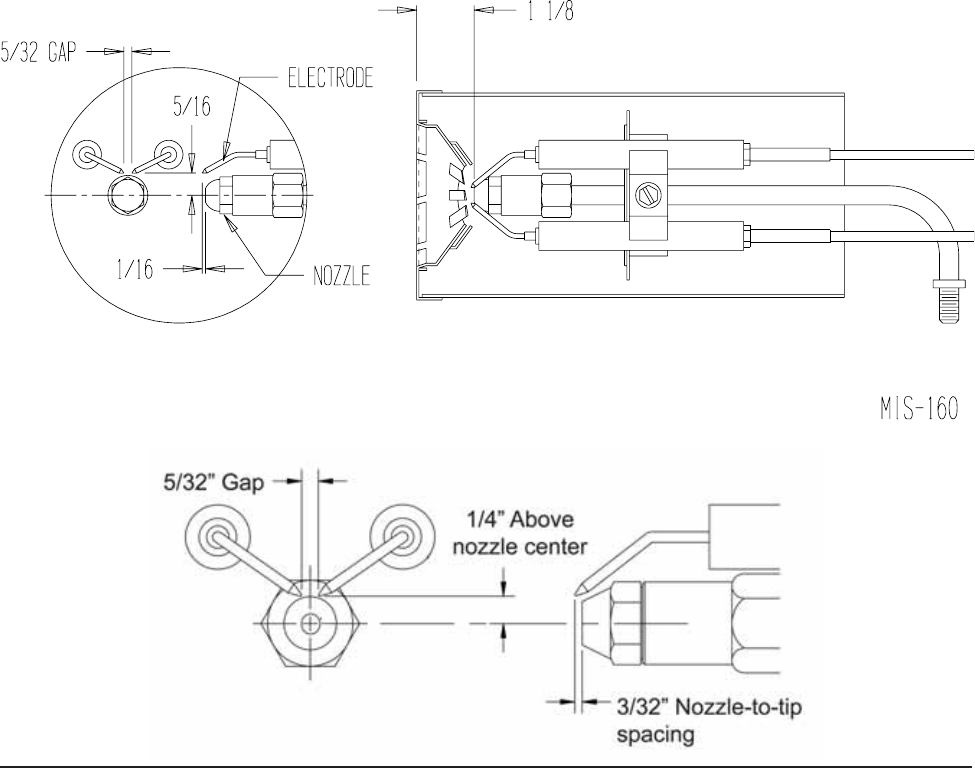

SPACING OF ELECTRODES

The electrodes should be spaced 5/32" apart. They

should extend 1/16" beyond the end and 5/16" above the

center of the nozzle tip as shown in Figures 10A & 10B.

GUN ASSEMBLY ADJUSTMENT

The gun assembly can be adjusted in the slot inside of

fan housing by loosening screw holding slot cover in

position. Nozzle tip should ordinarily be located 1-1/8"

behind the front face of the cone.

REMOVING GUN ASSEMBLY

Disconnect the oil line at the fan housing and remove

lock nuts on copper tube fitting. Loosen igniter hold

down clamps, then swing igniter up and backward. Gun

assembly can now be removed through this opening.

COMBUSTION AIR REQUIREMENTS

This furnace must be installed in a location where a

sufficient supply of combustion air is available for the

complete combustion of the fuel oil. Keep in mind that a

certain amount of excess air is required as well to ensure

complete combustion of the fuel oil.

When structures are constructed too tightly to supply

sufficient combustion air, air from outside the structure

is required to be brought in directly to the furnace. This

furnace has been conveniently designed to accept a

combustion air boot which is attached directly to the

outdoors by means of a 4" pipe. This pipe can be rigid or

flexible, but it is recommended that a metallic material

be used. Refer to Figure 11. The air boot used for this

design is a Field Controls model number CAS-2B-90E

that can be purchased through your local distributor.

Follow all installation procedures as specified in the

instructions packaged with the air boot kit.

NOTE - This accessory is not currently available for

Bard Models: FH110D48F, FH110D60F,

FLF110D48F and FLF110D60F with NX burners.

FIGURE 10A

ELECTRODE ADJUSTMENTS — AFG BURNERS

FIGURE 10B

ELECTRODE ADJUSTMENTS — NX BURNERS