20

BMC and BMC-6X Installation and Operation Manual

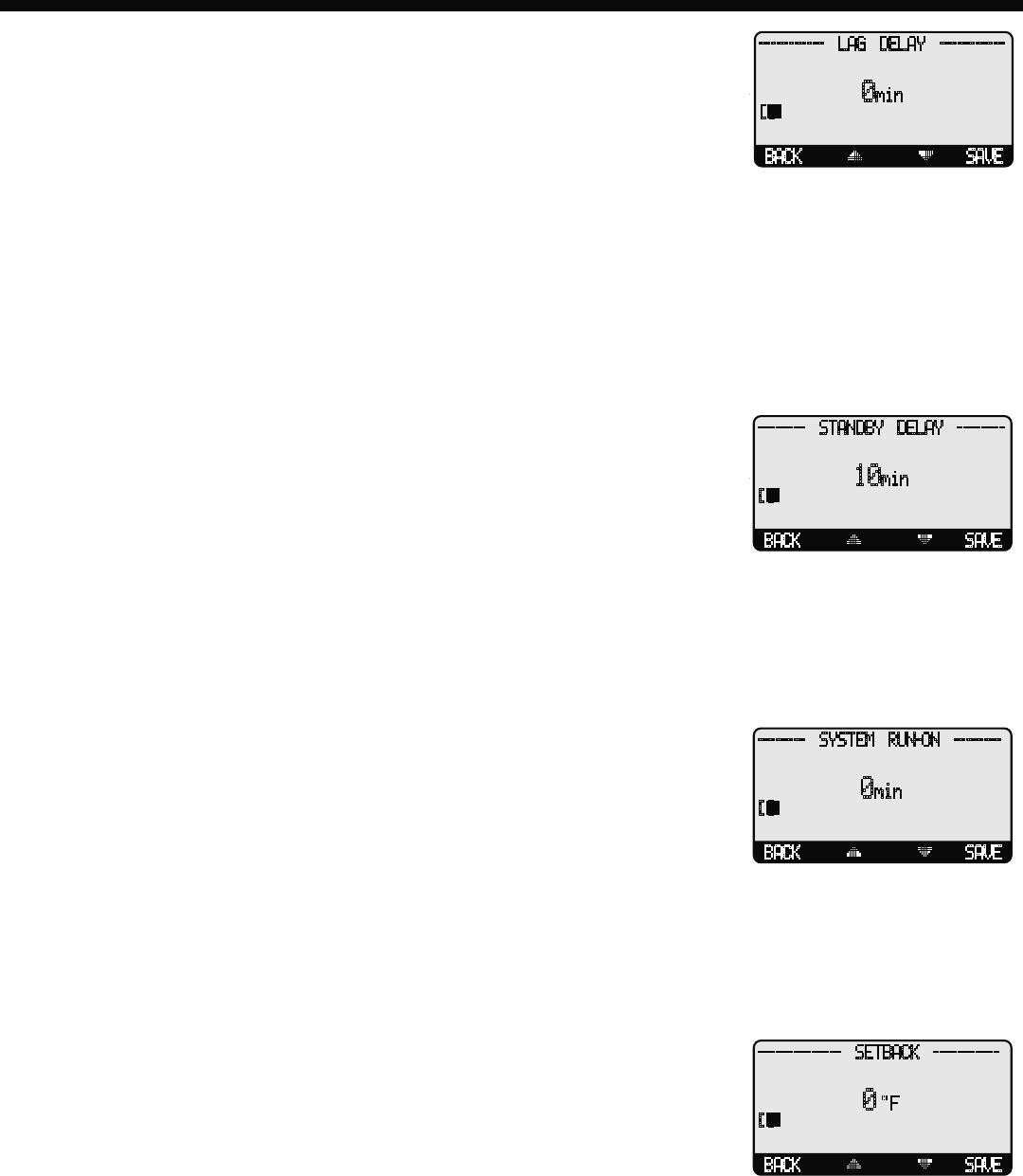

LAG DELAY

Adjustable from 0min to 60min Default: 0min

Button: MENU/<System Settings>/Lag Delay

• The Lag Delay requires the previous stage to remain at 100% modulation for the full

period of the Lag Delay before another Stage can be activated. For example, if the Lag

Delay was set to 10 minutes, the Lead Stage would need to remain at 100% modulation

for a full ten minutes (never backing down to even 99%) before a lag stage could be

activated. The Message Display Line will display Lag Delay and the remaining time.

BACK SAVE

----------- LAG DELAY -----------

0

min

[]

• Set the Lag Delay to 0 min when two or more Stages will generally be needed to hold the load.

• The Lag Delay is useful in installations where one unit should usually have enough output to hold the load unless it fails or load

conditions become extreme.

• The Lag Delay overrides the value of the Modulation Start % selected for each stage. Regardless of that setting, the previous

stage must reach 100% and stay there before the lag stage can be activated.

• The full Lag Delay must always elapse regardless of what happens to system temperature. Therefore, set the Lag Delay to 0 min

if you want smooth set point control using multiple units.

STANDBY DELAY

Adjustable from 1min to 60min Default: 10min

Button: MENU/<System Settings>/<More Settings>/Standby Time

• The Standby Delay only applies to boilers in Standby Mode. See Mode on page 25.

• A boiler can be set to be a Standby boiler using the Stage Menu.

• A Standby boiler can only be activated after all the boilers in Auto Mode have run at

100% modulation for the full Standby Time.

• Standby boilers are used for backup or extreme load conditions only. A Standby boiler

can never be a Lead Stage

BACK SAVE

-------- STANDBY DELAY --------

10

min

[]

• The full Standby Delay must always elapse regardless of what happens to system temperature. Therefore, shorter Standby

Times will result in smoother set point operation in extreme conditions. Longer Standby Times may prevent a Standby boiler

from firing if the other boilers can eventually meet the load, or if the load decreases.

SYSTEM RUN-ON

Adjustable from 0min to 360min Default: 0min

Button: MENU/<System Settings>/<More Settings>/System run-On

• The SYS relay will energize whenever the Outdoor temperature (OD) is below the

Outdoor Cutoff and the Shutdown is Open or the Tstat is closed. When the Outdoor

temperature increases 2°F above the Outdoor Cutoff after the last burner relay has de-

energized, the SYS relay will stay on for a period set by the System Run-On.

BACK SAVE

-------- SYSTEM RUN-ON --------

0

min

[]

• A common use for the System Run-On is to control a system pump in a heating system. The extra time helps transfer the heat

from the boilers to the heating system.

• The System Run-On time should be set based on the size and type of the boilers and pumps. In general, a boiler with low

water content and high horsepower will need a longer System Run-On than a boiler with the same horsepower and more water

content. (Refer to boiler manufacturer recommendation)

SETBACK

Adjustable from 0F°/0C° to 75F°/42C° Default: 0F°/0C°

Button: MENU/<System Settings>/<More Settings>/Setback

• The Setback feature can be used to provide the BMC with a lower temperature Set Point

when less load is required.

• The lower Set Point will appear on the main display indicating this condition.

• For example, if the calculated temperature is 180°F and the Setback is 20°F, then when

in Setback, the BMC will hold a Set Point of 160°F.

• A typical use for Setback is to provide less system temperature to a building during the

night or on the weekends when building is not occupied, but heat is still required.

• The amount of Setback selected is subtracted from the Set Point when a Setback Input

Signal is received or the Night Time schedule setting started.

BACK SAVE

-------------- SETBACK -----------

0

F

[]