• Installation • Start-Up • Maintenance • Parts

19Part No. 550-141-935/0602

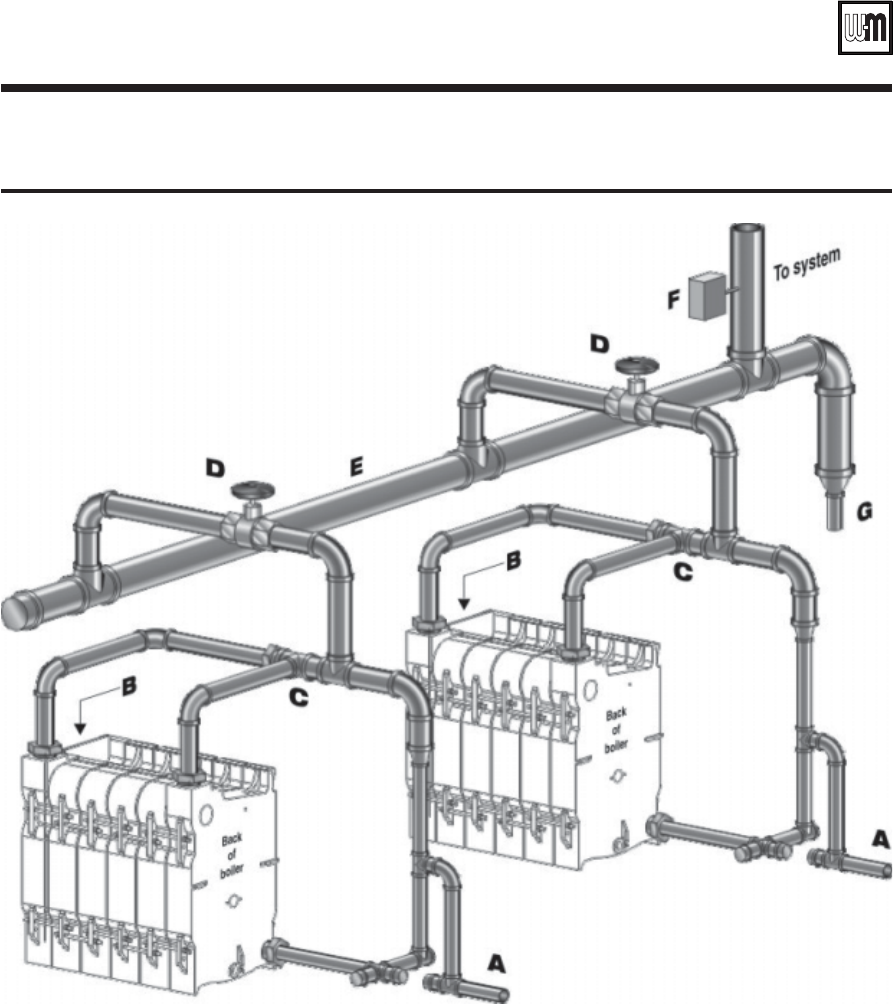

Figure 19 Multiple Steam Boiler Piping Gravity Condensate Return

Connect steam boiler piping (continued)8

A Pipe as shown for gravity return systems, connecting

point A to the wet gravity return.

For pumped-return systems, install boiler water level

control on each boiler with body mark at level indicated

in Figure 30 on page 30. Provide at point A either:

• Separate feed pumps and check valves for each

boiler, or . . .

• Single feed pump, with separate solenoid valve for

each boiler.

B For pumped-return systems, install a combination float

and thermostatic trap on each boiler to prevent flooding

of one boiler while other boiler is firing. Install trap in

skim tapping (see page 29). Connect traps to

condensate receiver.

Gravity-return systems are self-levelling if the wet

returns are piped to the common system wet return.

C Install boiler piping as shown in this manual (pages 16

through 19).

D Install stop valves per ASME code requirements.

For pump-return systems, if using automatic steam

valves, use only slow-opening automatic valves. Use a

Weil-McLain Boiler Control System (such as a BCP

panel) to open each steam valve automatically before

firing burner.

E Construct common supply drop header with pipe size

at least same size as largest boiler header size.

F Use:

• A Weil-McLain Boiler Control System (such as a BCP

panel) with header-mounted pressure control(s) to

sequence boilers, or . . .

• A steam pressure controller.

G Install drip line in common supply drop header.

Gravity-return: Pipe drip line to wet return.

Pumped-return: Use combination float and thermostatic

trap and drain to condensate receiver.