Sensor Installation Guidelines

We suggest you mount the sensor at a location in your process or system where

it reads an average temperature. Put the sensor as near as possible to the mate-

rial or space you want to control. Air flow past this sensor should be moderate.

The sensor should be thermally insulated from the sensor mounting.

See Chapter 4 for more information on DIP switch location and orientation.

Input Wiring

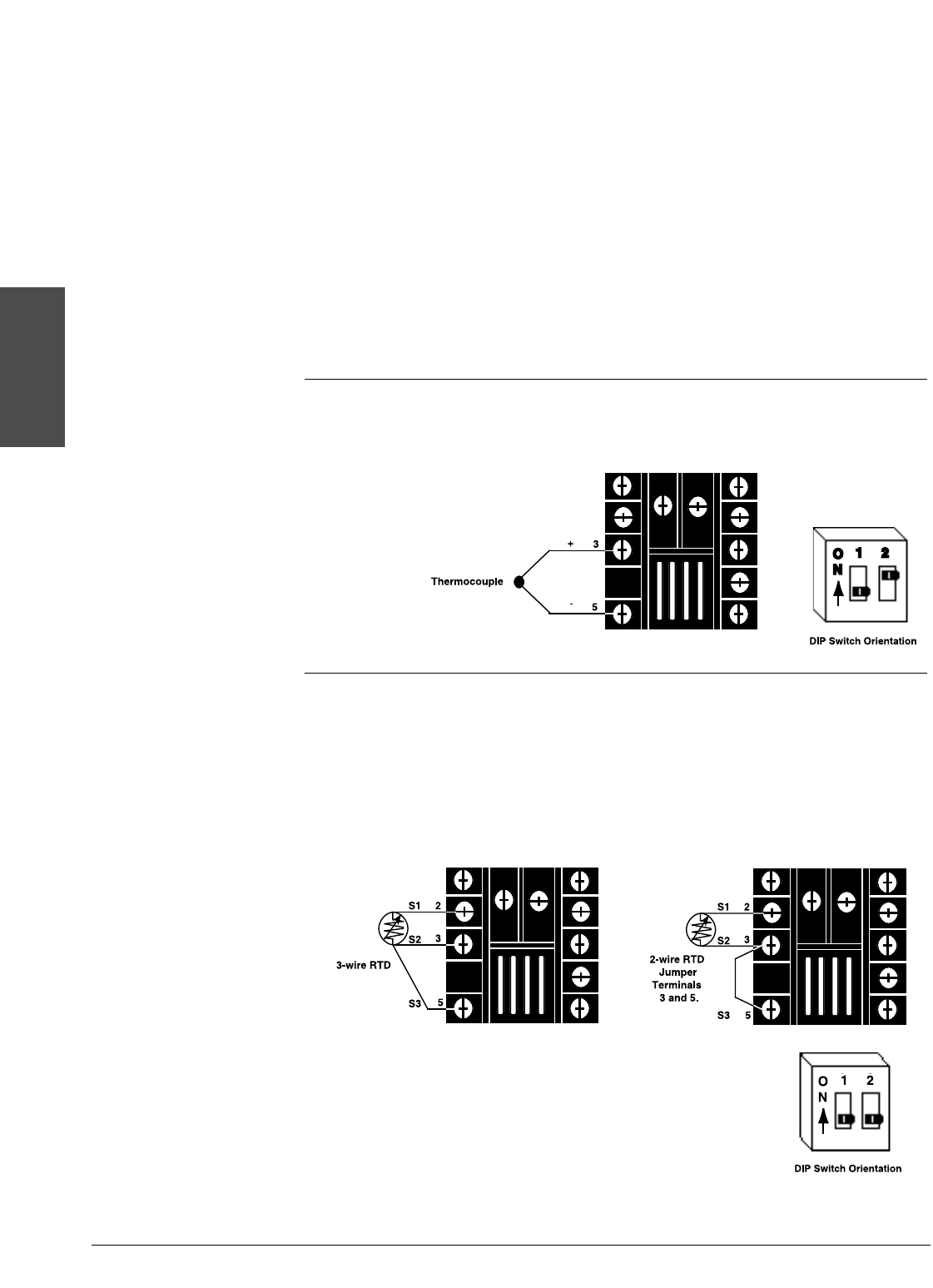

Figure 2.4a – Thermocouple

Extension wire for thermocouples must be of the same alloy as the thermo-

couple itself to limit errors.

Figure 2.4b – RTD (2- or 3-Wire) 100Ω Platinum

There could be a + 2°F input error for every 1Ω of lead length resistance

when using a 2-wire RTD. That resistance, when added to the RTD element

resistance, will result in erroneous input to the instrument. To overcome

this problem, use a 3-wire RTD sensor, which compensates for lead length

resistance. When extension wire is used for a 3-wire RTD, all wires must

have the same electrical resistance (i.e. same gauge, same length, multi-

stranded or solid, same metal).

Install and Wire

2.4 ■ Install and Wire Watlow Series 93

∫ç

WARNING: To avoid elec-

tric shock and damage to

property and equipment,

use National Electric

Code (NEC) safety prac-

tices when wiring and

connecting this unit to a

power source and to

electrical sensors or

peripheral devices.

Failure to do so could

result in injury or death.

NOTE:

When an external device

with a non-isolated cir-

cuit common is connect-

ed to the 4-20mA or dc

output, you must use an

isolated or ungrounded

thermocouple.