Waterford TARA T25 Direct Vent Freestanding Gas Stove

15

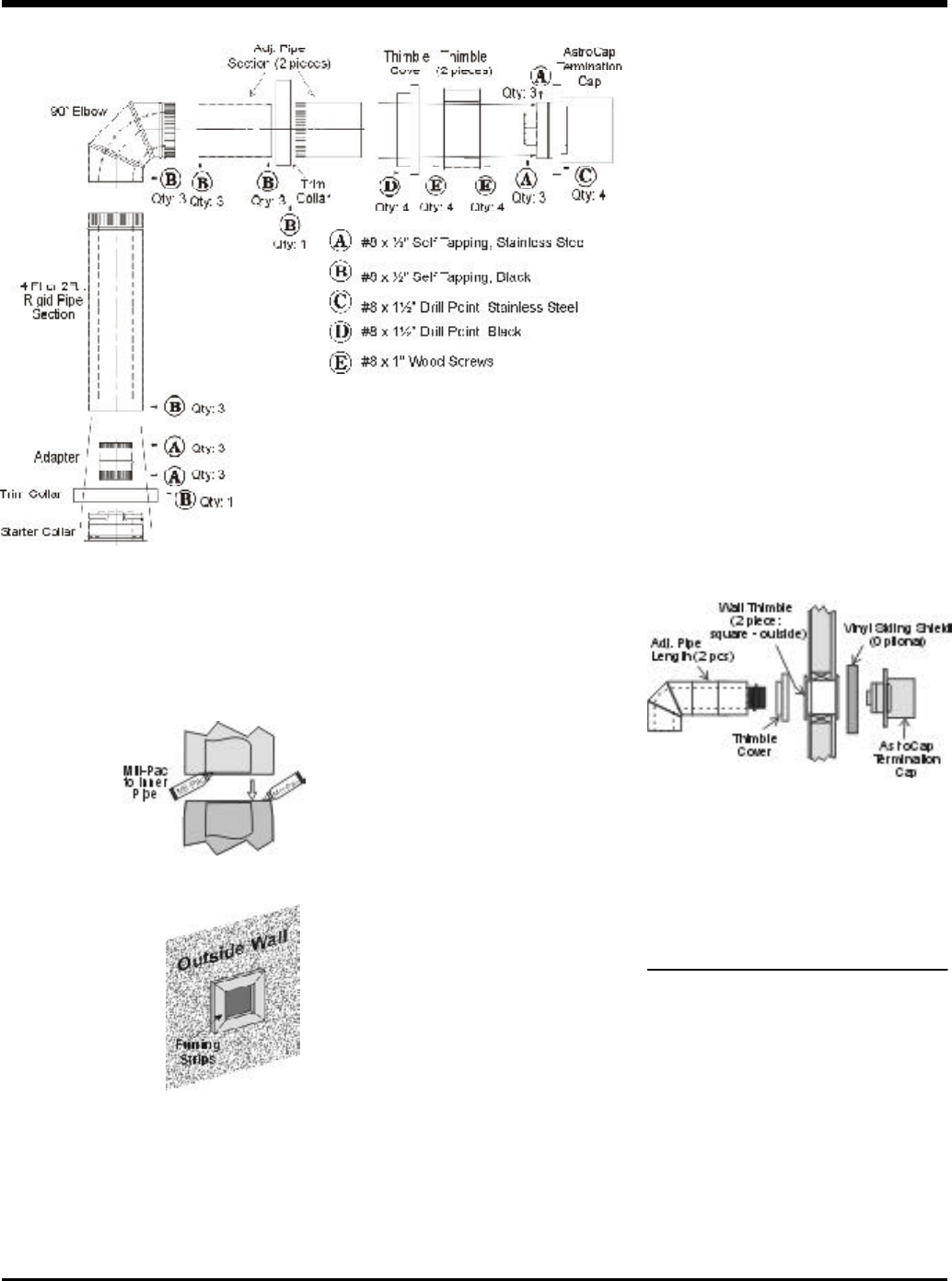

DURA-VENT

TERMINATION KIT

Planning Your Dura-Vent Installation

There are two basic types of Dura-Vent Direct

Vent System installations: horizontal termina-

tion and vertical termination. Confirm the max-

imum horizontal run and maximum vertical rise

from the diagram on page 18.

When planning your installation, it will be nec-

essary to select the proper length of vent pipe

for your particular requirements. For horizontal

installations, determine the minimum clearance

INSTALLATION

of 1-3/8"(35mm). Use Mill-Pac to seal and

secure with 3 of the #8 x 1/2" screws

(stainless steel).

4) Attach the adjustable pipe section to the

vent terminal using Mill-Pac and/or high

temperature silicone and attach with 3 of

the #8 x 1/2" screws (stainless steel).

Note: The pipe seam should be facing

down.

Note: To make the

installation

more aesthet-

ically pleasing,

we recom-

mend framing

out a square

that the cap can

be mounted

on.

Note: If installing termination on a siding

covered wall, a vinyl siding stand-

off or furring strips must be used

to ensure that the termination is

not recessed into the siding. For

vinyl siding standoff installation

refer to the Dura-Vent Termina-

tion instructions.

5) Slide the partially connected pipe and vent

terminal assembly through the wall thimbles

(from the exterior into the interior) and

secure the cap to the exterior wall with 4 of

the supplied screws (#8 x 1-1/2" drill point,

stainless steel). Note: pilot holes will need

to be drilled through the wall thimble on all

4 corners.

Note: The four screws provided for the

vent cap should be replaced with

appropriate fasteners for stucco,

brick, concrete, or other types of

sidings.

6) A bead of non-hardening mastic should be

run around both the termination and vinyl

siding standoff to prevent water from en-

tering and to make a tight seal between the

cap and the standoff.

7) Stretch the 4" dia. flex liner out fully and get

a trial fit of the liner onto the 4" dia. starter

collar.

8) Cut the 4" dia. flex liner to the desired size.

Hint: leave an extra 12" to 16" of length, this

will make the final assembly easier to work

with.

9) Secure the 4" dia. flex liner to the 4" adapter

with Mill-Pac and 3 of the #8 x 1/2" screws

(stainless steel).

10)Slide the decorative Thimble Cover over the

pipe sections and secure with 4 screws

(#8 x 1-1/2" drill point, black) to the wall.

11)Slide the 90

o

elbow (crimp end up), the 45

o

elbow and the 2 ft. or 4 ft. pipe section

(crimp end up) over the 4" dia. flex liner.

12)Slide the trim collar over the adjustable pipe

sections to cover the joint of the telescopic

section.

13)Install the spring spacers onto the pipe

sections.

14)Secure the 4" dia. flex liner with adapter

onto the stove collar. Put a bead of Mill-Pac

around the appliance adapter and secure

with 3 screws (#8 x 1/2, stainless steel).

15)Attach the 45

o

elbow onto the starter collar

by sealing with Mill-Pac and/or high tem-

perature silicone and securing with 3 of

the #8 x 1/2" (black) screws.

16)Attach the pipe section to the 45

o

elbow by

sealing with Mill-Pac and/or high tempera-

ture silicone and securing with 3 of the #8

x 1/2" screws (black). Pipe seams should

be facing the wall.

17)Attach the 90

o

elbow onto the pipe section

by sealing with Mill-Pac and/or high tem-

perature silicone and securing with 3 of

the #8 x 1/2" screws (black).

18)Slide the adjustable pipe section onto the

90

o

elbow. The flex may have to be com-

pressed back in order for the adjustable

pipe to properly mate to the elbow. Seal

with Mill-Pac and/or high temperature sil-

icone and secure with 3 of the #8 x 1/2"

screws (black). Pipe seams facing down.

18)Install the trim collar over the starter collar

and secure with a #8 x 1/2" screw (black).

If the pipe needs to be touched up, use only

Stove Brite High Temperature Metallic Black

Stove Paint.

NOTE: All inner joints must be sealed

with Mill-Pac. All outer joints may

be sealed with high temperature

silicone.

Hint: Apply the

sealant (Mill-

Pac and/or high

temperature sil-

icone) to the out-

er pipe before

connecting the

inner pipe.