MUA-PRC001-EN22

Dimension and

Weights

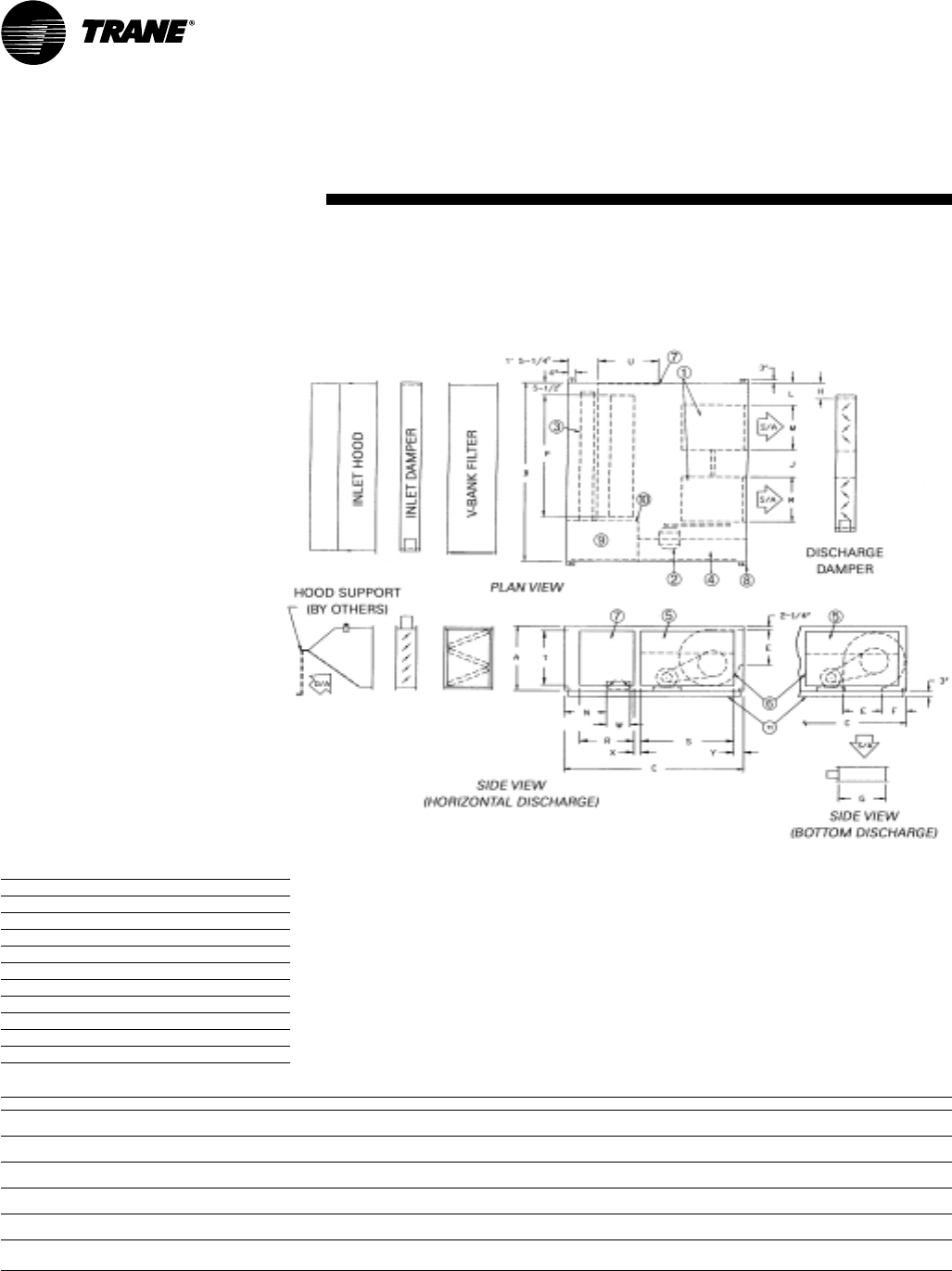

Inlet Hood Support (By Others)

• The purpose of hood support is to

support the weight of the unit

accessories which are attached to the

inlet of the basic unit.

• The hood support can be made from

two, 2” x 2” x ¼” angle iron.

• One angle iron support should be

located in, or close to, the outer corners

of the hood. The supports can be bolted

to the hood.

Horizontal Arrangement — Double Blower

Return Air Opening Downstream of Burner

Motorized Return Air Damper — Motorized 75/25 Damper

215 218 220 222 225 230

Table DW-4

Model A B C E F G H J L M N P R S T U W X Y

215 3' 0" 7' 10" 6' 5" 1' 4" 1' 0-

3/8

" 1' 7-

7/8

"7-

1/8

" 1' 10-½" 7-

7/8

" 1’6-

15/16

" 1' 7" 5' 5-¾" 1’9” 2’9” 2’5” 1’9” 1' 2-

¼

" 4-½" 5-¾"

(914) (2388) (1956) (406) (314) (505) (181) (572) (200) (481) (483) (1670) (533) (838) 737) (533) (362) (114) (146)

218 3' 0" 7' 10" 6' 5" 1' 7" 1' 0-

3/8

" 1' 7-

7/8

"7-

1/8

" 1' 4" 7-

7/8

" 1’10-

1/16

" 1' 7" 5' 5-¾" 1’9” 2’9” 2’5” 1’9” 1' 2-¼" 4-½" 5-¾"

(914) (2388) (1956) (483) (314) (505) (181) (406) (200) (560) (483) (1670) (533) (838) 737) (533) (362) (114) (146)

220 4' 0" 10' 10" 8' 0" 2' 0-

7/8

" 1' 1-

3/16

" 2' 4-¼" 11-½" 2' 5-½" 1' 0-

3/8

" 2’1-

1/16

" 1' 7" 7' 3-

3/8

" 2’9” 3’2” 3’3” 2’7” 1' 2-¼" 0' 8" 7-

1/8

"

(1219) (3302) (2438) (632) (335) (718) (292) (749) (314) (637) (483) (2219) (838) (965) (991) (787) (362) (203) (181)

222 4' 0" 10' 10" 8' 0" 2' 3-

3/8

" 1' 1-

3/16

" 2' 4-¼" 11-½" 2' 0-

5/8

" 1' 0-

3/8

" 2' 3-

9/16

" 1' 7" 7' 3-

3/8

" 2’9” 3’2” 3’3” 2’7” 1' 2-¼" 0' 8" 7-

1/8

"

(1219) (3302) (2438) (695) (335) (718) (292) (625) (314) (700) (483) (2219) (838) (965) (991) (787) (362) (203) (181)

225 5' 0" 12' 10" 8' 0" 2' 7-

3/8

" 1' 5-

9/16

" 3' 1-¾" 1' 2-½" 3' 1-

5/8

" 1' 3-

3/8

" 2' 7-½" 11-

13/16

" 9' 3-

3/8

" 2’1-¾” 3’2” 4’3” 1’8” 1' 8-¼" 1' 2" 6-¼"

(1524) (3912) (2438) (797) (446) (959) (368) (956) (391) (800) (300) (2829) (654) (965) (1295) (508) (514) (356) (159)

230 5' 0" 12' 10" 8' 0" 3' 0-

7/8

" 1' 5-

9/16

" 3' 1-¾" 1' 2-½" 2' 2-

5/8

" 1' 3-

3/8

" 3' 1" 11-

13/16

" 9' 3-

3/8

" 2’1-¾” 2’9” 4’3” 1’8” 1' 8-¼" 1' 2" 6-¼"

(1524) (3912) (2438) (937) (446) (959) (368) (676) (391) (940) (300) (2829) (654) (838) (1295) (508) (514) (356) (159)

Notes:

1. To permit blower shaft replacement, the side opposite the controls should have clearance equal to the unit width.

2. Minimum of 5’ for serviceability clearance.

3. Supply duct connection (by others) to be “pants-legged”from unit discharge.

Item Unit Components

1 Centrifugal Supply Fan

2 Fan Motor

3 Heat Source (Line Burner)

4 Control Cabinet

5 Hinged Control Cabinet Access Door

6 Motor and Drive Access Plate

7 Access Door

8 Removable Suspension Lifting Lug

9 Manifold Compartment

10 Observation Port

11 Unit Base

• The bottom of the angle iron support

should be fitted with a base. The base

can sit on the roof and does not have

to be fixed to the roof. An isolation pad

may be put between the base and the

roof.