– 69 –

9. CIRCUIT CONFIGURATION AND CONTROL SPECIFICATIONS

9-1. Indoor Control Circuit

9-1-1. Outline of Main Controls (This content is same 9-2-2. of Outdoor Content)

RAV-SM562AT-E, RAV-SM802AT-E, RAV-SM1102AT-E, RAV-SM1402AT-E

1. Pulse Motor Valve (P.M.V.) control

1) PMV is controlled with 50 to 500 pulses during operation, respectively.

2) In cooling operation, P.M.V. is controlled with the temperature difference between TS sensor and TC

sensor.

3) In heating operation, P.M.V. is controlled with the temperature difference between TS sensor and TE

sensor.

4) For the temperature difference in items 2) and 3), 1 to 5K is aimed as the target in both cooling and

heating operations.

5) When the cycle excessively rose in both cooling and heating operations, PMV is controlled by TD sensor.

The aimed value is usually 105°C for SM562 and 100°C for SM802, SM1102, SM1402 in both cooling

and heating operations.

REQUIREMENT

A sensor trouble may cause a liquid back-flow or abnormal overheat resulting in excessive shortening of

the compressor life. In a case of trouble on the compressor, be sure to check there is no error in the

resistance value an the refrigerating cycle of each sensor after repair and then start the operation.

a

b

c

d

e

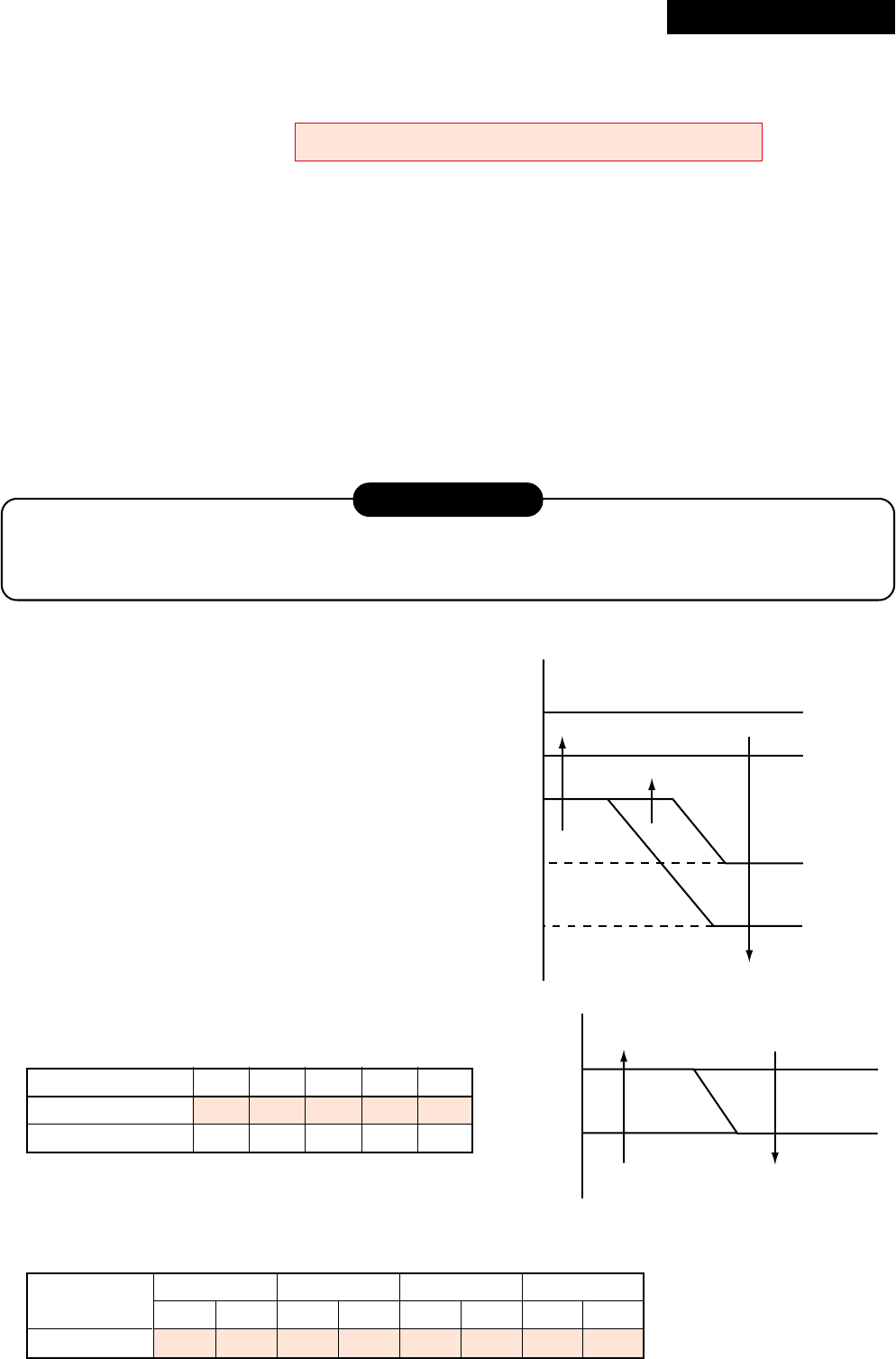

TD [˚C]

Error stop ("P03" display with 4 times of error counts)

As command is

Frequency down

Frequency holding

Frequency slow-up

(Up to command)

I1

1–0.5

[A]

Frequency down

Normal operation

Hold

Hold

3. Current release control

The output frequency and the output voltage are controlled by AC current value detected by T02 on the

outdoor P.C. board so that input current of the inverter does not exceed the specified value.

* For the cooling only models,

only COOL is objective.

2. Discharge temperature release control

1) This function controls the operation frequency, that

is, lowers the operation frequency when the dis-

charge temperature has not lower or the discharge

temperature has rapidly risen during P.M.V. control.

It subdivides the frequency control up to a unit of

0.6Hz to stabilize the cycle.

2) When the discharge temperature is detected in an

abnormal stop zone, the unit stops the compressor

and restarts after 2 minutes 30 seconds.

The error counter is cleared when it has continued

the operation for 10 minutes.

If the abnormal stop zone has been detected by 4

times without clearing of counter, an error “P03” is

displayed.

* The cause is considered as excessively little

amount of refrigerant, defective PMV, or clogging

of cycle.

[°C]

SM562

SM802, 1102, 1402

abcde

117 107 103 100 93

111 106 100 95 90

Objective

model

I1 value [A]

SM562

COOL HEAT

10.1 12.0

SM802

COOL HEAT

12.2 14.0

SM1102

COOL HEAT

18.9 19.7

SM1402

COOL HEAT

19.7 19.7

Revised : Nov. 2006