– 87 –

11-9-5. Checking Method for Each Part

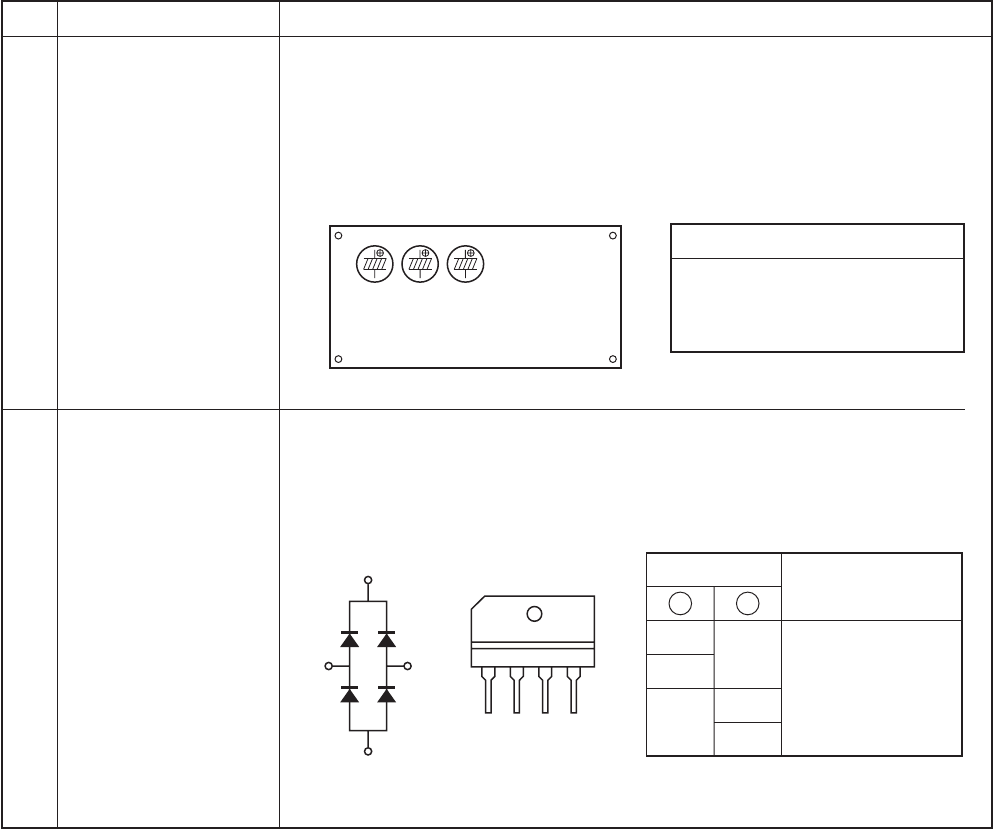

MCC-5009

Soldered

surface

Heat sink IGBT side

C12 C13 C14

Resistance value

in good product

∞

Tester rod

+ –

~

2

~

3

~

2

~

3

–

4

~~

~

+ –~

1

123

(DBO1)

4

4

23

+

1

+

–

No.

1

2

Part name

Electrolytic capacitor

(For boost, smoothing)

Diode block

Checking procedure

1. Turn OFF the power supply breaker.

2. Discharge all three capacitors completely.

3. Check that safety valve at the bottom of capacitor is not broken.

4. Check that vessel is not swollen or exploded.

5. Check that electrolytic liquid does not blow off.

6. Check that the normal charging characteristics are shown in continuity test by

the tester.

Case that product is good

Pointer swings once, and returns

slowly. When performing test

once again under another polarity,

the pointer should return.

C12, C13, C14 → 500µF/400V

1. Turn OFF the power supply breaker.

2. Completely discharge the four electrolytic capacitors.

3. Remove the diode block from the PCB (which is soldered in place).

4. Use a multimeter with a pointer to test the continuity, and check that the

diode block has the proper rectification characteristics.

10 to 20 Ω when the multimeter probe

is reversed