– 82 –

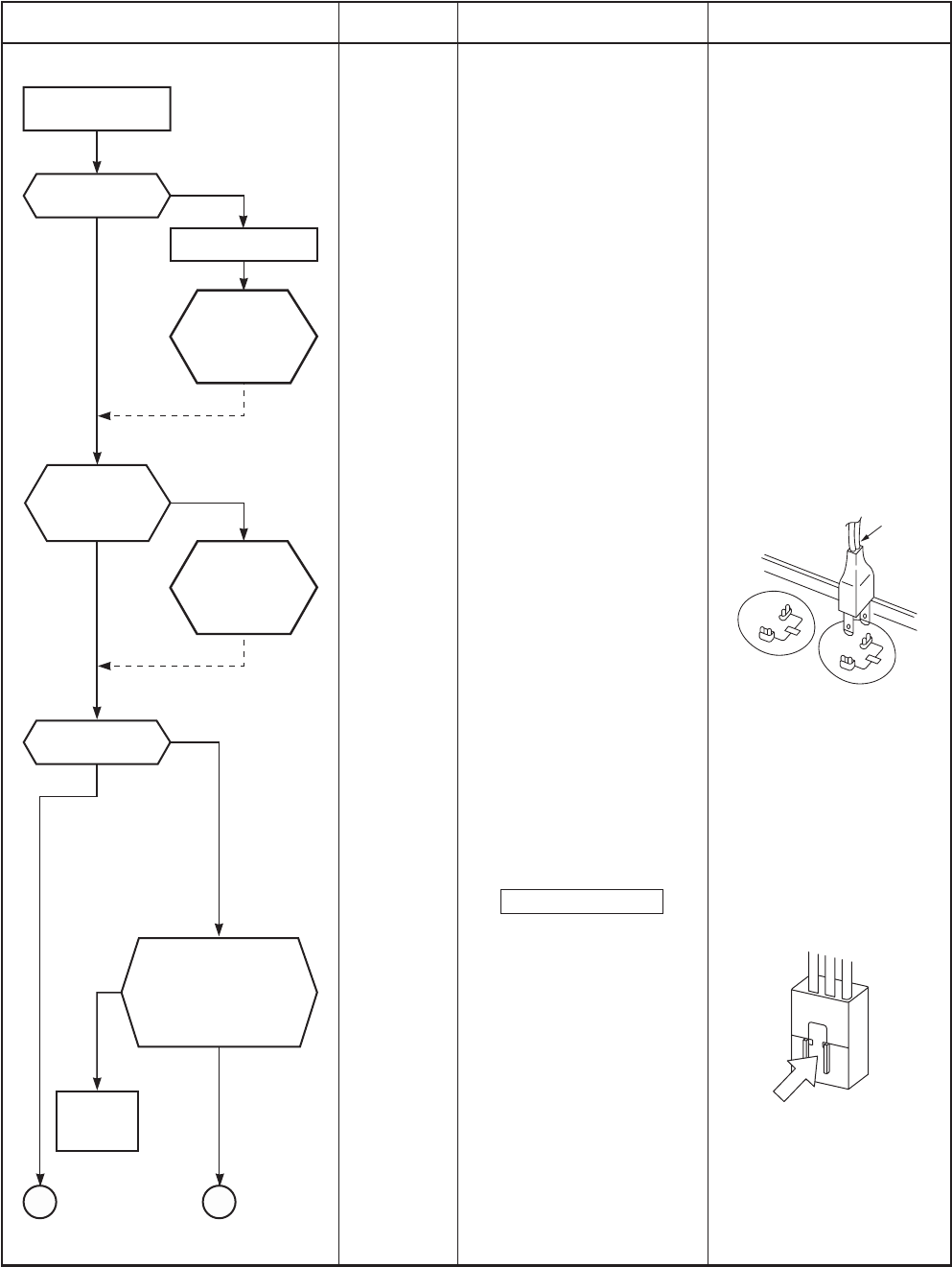

11-8. How to Diagnose Trouble in Outdoor Unit

11-8-1. Summarized Inner Diagnosis of Inverter Assembly

Table 11-8-1

Replace

outdoor

fan motor.

Remove connector

of compressor.

NG

NG

NG

NO

OK

OK

OK

YES

Check 25A fuse

(Part No.F01).

Does outdoor

fan rotate?

Replace fuse.

Check

electrolytic

capacitor, diode

block (DB01),

etc.

Check

electrolytic

capacitor, diode

(DB01),

etc.

Remove connector

CN300 of outdoor fan

motor, and using a

tester, check resistance

value between every

phases at motor side.

Check

terminal voltage

of electrolytic

capacitor.

BA

Discharging position

(Discharging period

10 seconds or more)

Plug of

soldering

iron

Diagnosis/Process flowchart Item

Preparation

Check

Check

Operation

Measure-

ment

Check

Stop

Check

Measure-

ment

Contents

Tu r n “OFF” the power supply

breaker, and remove 3P

connector which connects

inverter and compressor.

• Check whether 25A fuse

on the control board

assembly is blown or not.

(F01)

Turn on the power breaker,

and operate the air condi-

tioner in COOL mode by time

shortening.

Measure terminal voltage of

the electrolytic capacity.

500µF:400WV × 3

After operation, turn off the

power breaker after 2

minutes 20 seconds passed,

and discharge the electrolytic

capacitor by soldering iron.

Check voltage between

motor phases.

• Is not winding between

-

‚

-

, or

-

opened

or short-circuited?

• Is not frame grounded with

,

, or

?

Summary

If fuse was blown, be sure to

check the electrolytic

capacitor and diode block.

(DB01)

• Connect discharge

resistance (approx. 100Ω,

40W) or soldering iron

(plug) between +, –

terminals of the electrolytic

capacitor (500µF) of C14

(with printed CAUTION

HIGH VOLTAGE) on P.C.

board.

OK if 500µF →

DC280 to 380V

Remove CN300 while

pushing the part indicated

by an arrow because CN300

is a connector with lock.

→ Resistance between

phases should be

approx. 55 to 77Ω

→ Should be 10MΩ or

more.