12

G. Cleanup and joint movement

Remove all excess cement from around the pipe and fitting

with a dry cotton rag. This must be done while the cement is

still soft.

The joint should not be disturbed immediately after the

cementing procedure, and sufficient time should be allowed

for proper curing of the joint. Exact drying time is difficult to

predict because it depends on variables such as temperature,

humidity and cement integrity. For more specific information,

you should contact your solvent cement manufacturer.

STEP G

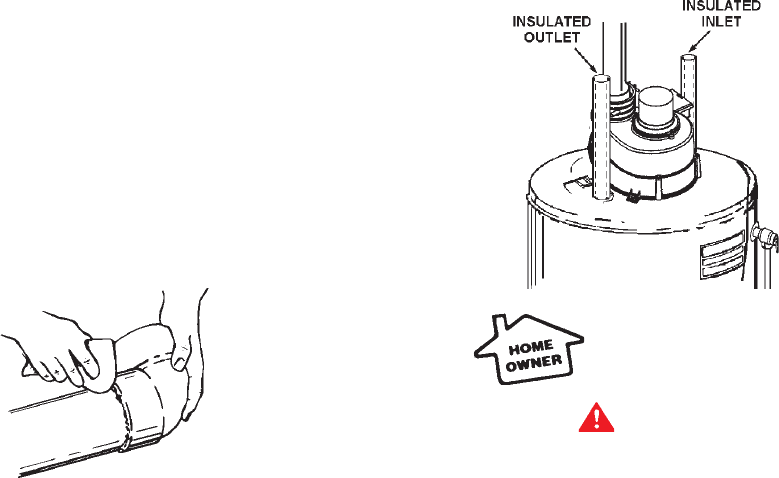

T & P VALVE and PIPE INSULATION

Remove insulation for T & P Valve and pipe connections from

carton.

Fit pipe insulation over the in-coming cold water line and the hot

water line. Make sure that the insulation is against the top cover

of the heater.

Fit T & P valve insulation over valve. Make sure that the insulation

does not interfere with the lever of the T & P valve.

Secure all insulation using tape.

OPERATION

WARNING

NEVER OPERATE THE HEATER WITHOUT FIRST BEING

CERTAIN IT IS FILLED WITH WATER AND A TEMPERATURE

AND PRESSURE RELIEF VALVE IS INSTALLED IN THE RELIEF

VALVE OPENING OF THE HEATER. DO NOT ATTEMPT TO

OPERATE HEATER WITH COLD WATER INLET VALVE CLOSED.

TO OPERATE THE WATER HEATER

FILLING

1. Close the heater drain valve by turning handle clockwise

Fig. 1 (T)

2. Open a nearby hot water faucet to permit the air in the system

to escape.

3. Fully open the cold water inlet pipe valve (allowing the heater

and piping to be filled. Fig. 1(M)

4. Close the hot water faucet as water starts to flow from the

faucet.

5. The heater is ready to be operated.