11

RECOMMENDED BRUSH* SIZE FOR PRIMER

AND CEMENT APPLICATIONS

Nominal Pipe Size Brush Width

(IPS) (INS.)

2 1-1/2

3 1-1/2 - 2-1/2

*USE ONLY NATURAL BRISTLE

3. MAKING THE JOINT

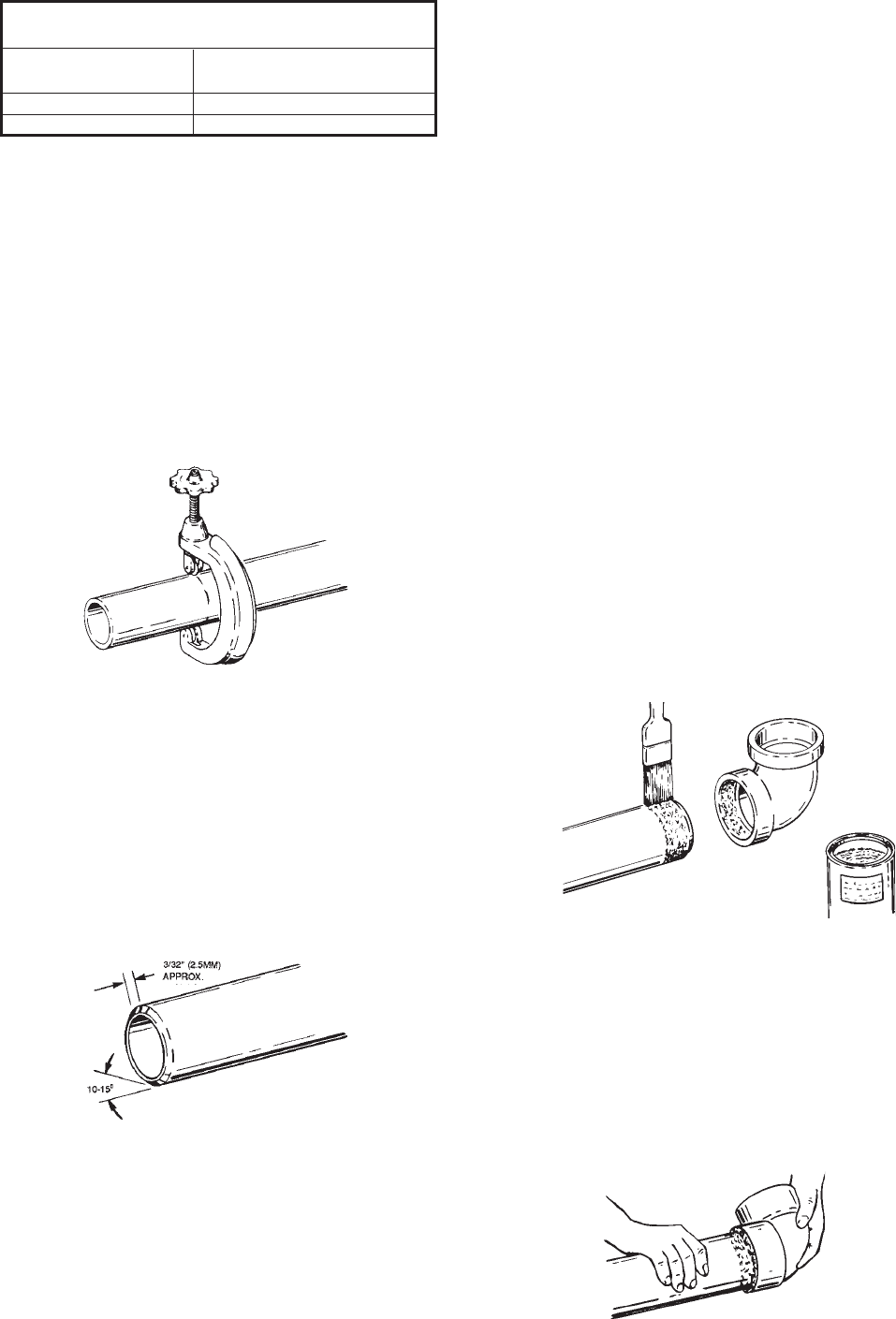

A. Cutting

Pipe must be squarely cut to allow for the proper interfacing

of the pipe end and the fitting socket bottom. This can be

accomplished with a miter box saw or wheel type cutter. Wheel

type cutters are not generally recommended for larger

diameters since they tend to flare the corner of the pipe end.

If this type of cutter is used, the flare on the end must be

completely removed.

NOTE: Power saws should be specifically designed to cut plastic

pipe.

STEP A

B. Deburring

Use a knife, plastic pipe deburring tool, or file to remove burrs

from the end of small diameter pipe. Be sure to remove all

burrs from around the inside as well as the outside of the

pipe. A slight chamfer (bevel) of about 10°-15° should be

added to the end to permit easier insertion of the pipe into the

end of the fitting. Failure to chamfer the edge of the pipe may

remove cement from the fitting socket, causing the joint to

leak.

STEP B

C. Test dry fit of the joint

Tapered fitting sockets are designed so that an interfaced fit

should occur when the pipe is inserted about 1/3 to 2/3 of the

way into the socket. Occasionally, when pipe fitting

dimensions are at the tolerance extremes, it will be possible

to fully insert dry pipe to the bottom of the fitting socket. When

this happens, a sufficient quantity of cement must be applied

to the joint to fill the gap between the pipe and fitting. The gap

must be filled to obtain a strong, leak-free joint.

D. Inspection, cleaning, priming

Visually inspect the inside of the pipe and fitting sockets and

remove all dirt, grease or moisture with a clean dry rag. If

wiping fails to clean the surfaces, a chemical cleaner must

be used. Check for possible damage such as splits or cracks

and replace if necessary.

Depth-of-entry

Marking the depth of entry is a way to check if the pipe has

reached the bottom of the fitting socket in Step F. Measure

the fitting depth and mark this distance on the pipe O.D. You

may want to add several inches to the distance and make a

second mark as the primer and cement will most likely destroy

your first one.

Apply primer to the surface of the pipe and fitting socket with

a natural bristle brush (see chart on page 11). This process

softens and prepares the PVC or CPVC for the solvent

cementing step. Move quickly and without hesitation to the

cementing procedure while the surfaces are still wet with

primer.

E. Application of solvent cement

• Apply the solvent cement evenly and quickly around the

outside of the pipe at a width a little greater than the depth

of the fitting socket.

• Apply a light coat of cement evenly around the inside of the

fitting socket. Avoid puddling.

• Apply a second coat of cement to the pipe end.

NOTE: Cans of cement and primer should be closed at all times

when not in use to prevent evaporation of chemicals and

hardening of cement. They are also very flammable and should

be kept away from heat or flame.

STEP E

F. Joint assembly

Working quickly, insert the pipe into the fitting socket bottom

and give the pipe or fitting a 1/4" turn to evenly distribute the

cement. Do not continue to rotate the pipe after it has hit the

bottom of the fitting socket. A good joint will have sufficient

cement to make a bead all the way around the outside of the

fitting hub. The fitting will have a tendency to slide back while

the cement is still wet so hold the joint together for about 15

seconds.

STEP F