7

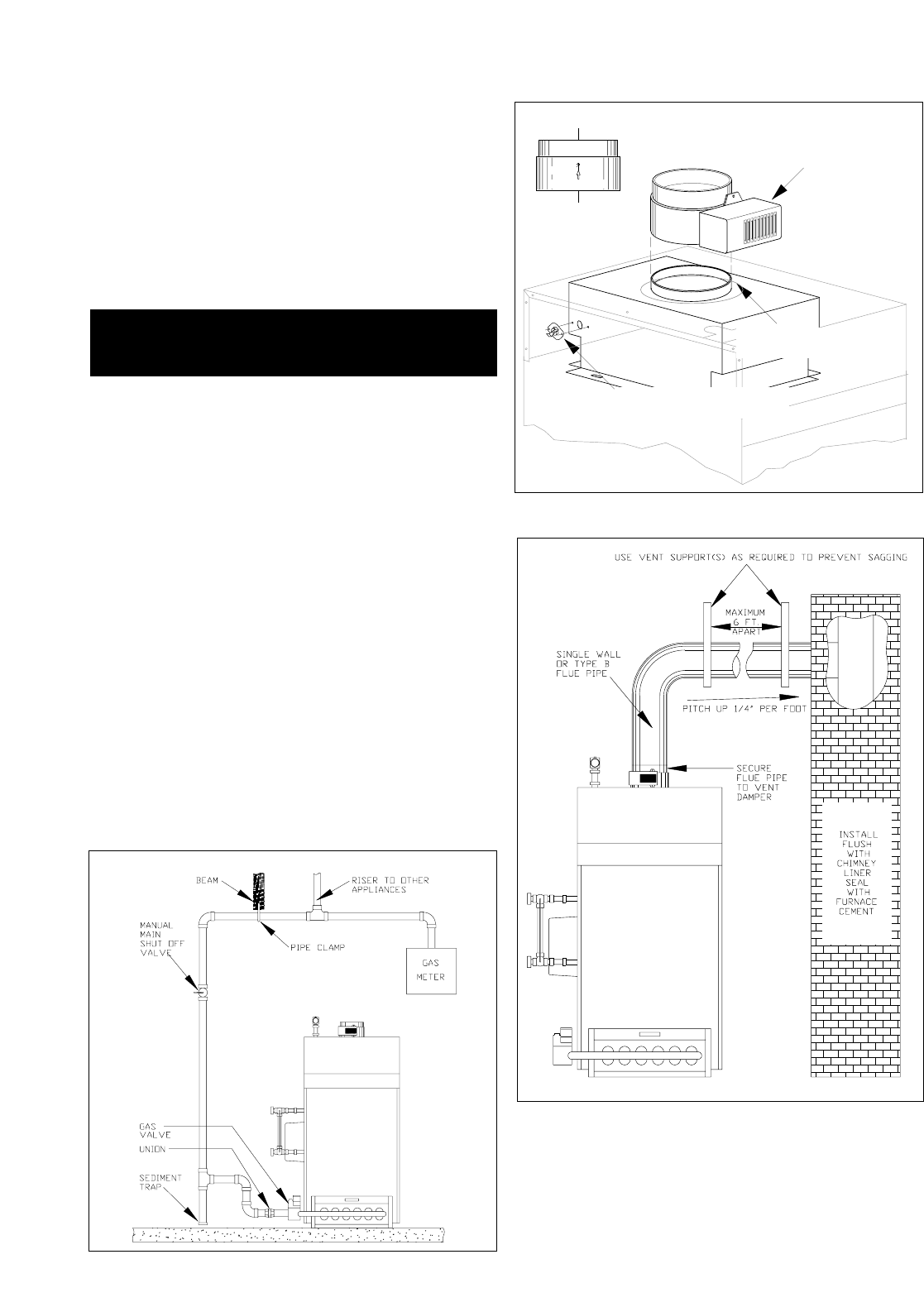

FIGURE 2.5: ATTACHING VENT DAMPER TO DRAFT

DIVERTER & FLUE PIPE

FLOW DIRECTION

ARROW POINTS UP

(REAR VIEW)

MAKE SURE MOTOR IS

LOCATED ON FRONT SIDE

CLOSED OPEN

FLOW DIRECTION

MOUNT VENT DAMPER

OVER DRAFT DIVERTER

INSTALL SWITCH IN

OPENING

ON DRAFT DIVERTER

ADDITIONAL CHIMNEY REQUIREMENTS

Chimney condition is of paramount importance for a safe and

efficient boiler installation. All installations must include a

chimney inspection by a qualified individual or agency. Chim-

ney construction materials must be compatible with the fuel

being used (See Figure 2.5A).

Particular attention should be paid on all oil-to-gas conver-

sions. Soot may have accumulated in chimney and/or

degraded chimney liner. Most utilities require complete chim-

ney cleaning. Others may require installation of new liner,

spill switches or other chimney upgrades. Check with local

utility for required safety precautions.

STEP 5: INSTALLING/TESTING GAS PIPING

Connect the gas piping from the meter to the boiler using a

pipe size which will result in a pressure drop of less than 0.3"

W.C. for natural gas or 0.5" W.C. for propane. See Figure 2.7

for the appropriate gas pipe sizing and example.

Good piping practices should be followed at all times. See

Figure 2.6 for a typical gas piping arrangement. All piping

must be supported by hangers, not by the boiler or its acces-

sories.

Install a full-sized sediment trap at the low point in gas line

upstream of gas valve. Install a non-restrictive lubricated plug

valve in the gas line close to the boiler. Install a ground joint

union at the gas valve inlet to allow for servicing. Check local

codes and utilities for any special requirements and proce-

dures.

Pipe joint compound (pipe dope) must be compatible with the

fuel (natural gas or propane) being used.

FIGURE 2.6: TYPICAL GAS PIPING

DANGER: A chimney which does not meet modern

safety standards will result in a fire or deadly carbon

monoxide poisoning of the building residents.

FIGURE 2.5A: VENTING