SECTION 3: START-UP & OPERATION

SEQUENCE OF OPERATION

For sequence of operation of the particular boiler being

installed, refer to Figures 2.8, 2.9, 2.10 and 2.11 in Section 2

of this manual.

Spill and rollout switches are mounted on all GB200 boilers.

The spill switch detects the escape of combustion products

through the draft diverter relief opening and interrupts the

power to the gas valve preventing unsafe boiler operation.

Escape of flue products could be caused by a blocked or col-

lapsed chimney or inadequate chimney draft. This is a manu-

al reset-type device and can be reactivated by depressing

the spill switch reset button mounted on the left of the boiler’s

draft diverter (see Figure 2.1 for switch location).

The rollout switch prevents flame rollout from the boiler com-

bustion chamber, caused by blocked boiler flue passage-

ways, by interrupting power to the gas valve to prevent

unsafe boiler operation. This is a manual reset-type device

and can be reactivated by depressing the rollout switch reset

button mounted on the lower front jacket panel (see Figure

2.1 for switch location). Flue passages must be inspected by

a qualified installer if this problem occurs, prior to switch

replacement.

PRIOR TO START-UP

Fill system with water until the water level indicator (sight

glass) is approximately 2/3 full. This water level is 23" from

the surface on which the boiler sits.

SYSTEM START-UP & ADJUSTMENTS

Safe lighting and other performance criteria were met with

the gas manifold and control assembly provided on the boiler

when the boiler underwent tests specified in ANSI Z21.13-

LATEST EDITION

1. Check combination gas valve on boiler and make sure it

is in the OFF position.

2. For vent damper-equipped models, with the thermostat

set to call for heat, observe that vent damper position

indicator rotates to the open position (see Figure 2.5).

Damper must be in the open position when appliance

main burner is operating.

a. After damper opens, spark should appear at the pilot

ignition electrodes.

b. Set thermostat to no longer call for heat. Spark should

stop. Observe that damper position indicator rotates to

the closed position.

c. Set thermostat to call for heat.

3. Light the boiler. For Model GB200 boilers with intermit-

tent pilot, see lighting instruction on Page 14.

4. Observe pilot and main burner flame (see Figure 3.2).

All burner ports should be ignited and burn with a steady

blue flame.

CAUTION: Never leave the job with yellow burning

flames. This condition indicated poor combustion and

will quickly carbonize the boiler, reducing efficiency and

boiler life. It may also be an indication of improper vent-

ing or combustion air supply. If unable to adjust flame

properly, consult your local utility.

5. Boilers are shipped from the factory with the primary air

shutters on the main burner wide open. It is recommend-

ed these air shutters be left in the wide open position

unless there is lifting of the flame above the burner ports.

If there is lifting, the air shutters should be gradually

closed until the lifting is eliminated. It may also be neces-

sary to adjust the primary air shutters if the input rate is

reduced by a change in the orifices.

6. After burner has been in operation for about 10 minutes,

check gas input rate to boiler as follows:

a. Make sure all appliances served by the meter are

turned off during timing of gas input rate to the boiler.

b. Measure the time in seconds that it takes for the boiler

to use 10 cubic feet of gas. Divide 36,000 by the number

of seconds (this is the number of cubic feet of gas used

per hour). Multiply this figure by the heating value of the

gas to obtain Btu input per hour.

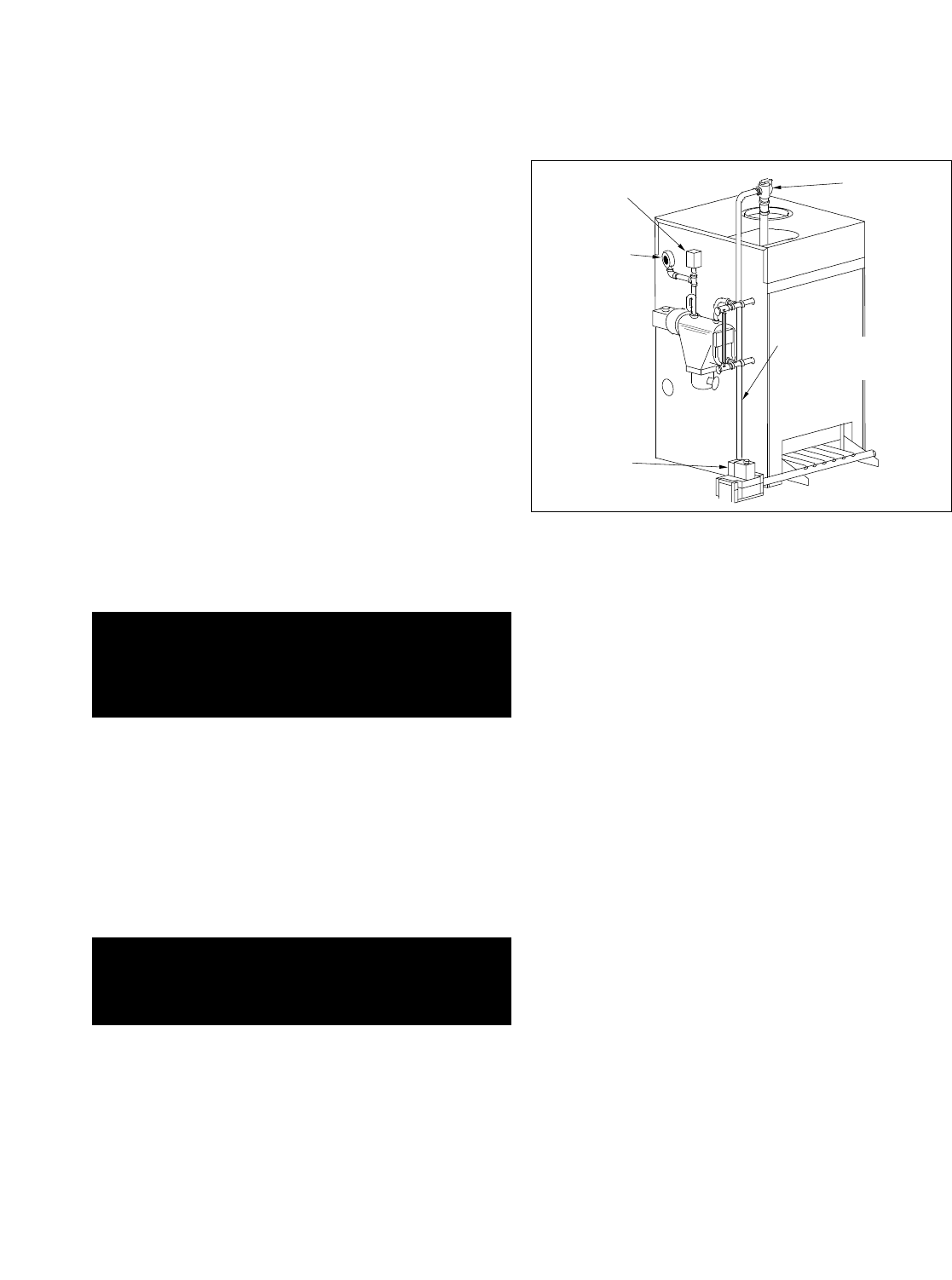

FIGURE 3.1: STEAM CONTROL ARRANGEMENT

WARNING: If boiler cannot be restored to normal

operation after re-setting of spill switch, or if flame

rollout switch has tripped, do not attempt to put the

boiler in operation. Immediately contact a qualified

service professional.

WARNING: Keep boiler area clear and free from com-

bustible materials, gasoline and other flammable

vapors and liquids. Otherwise fire or explosion may

result.

PRESSURE

RELIEF VALVE

OPTIONAL

FLOAT

LOW WATER

CUT OFF

PRESSURE

CONTROL

PRESSURE

GAUGE

GAS VALVE

PRESSURE RELIEF

VALVE DISCHARGE

PIPING

11