14

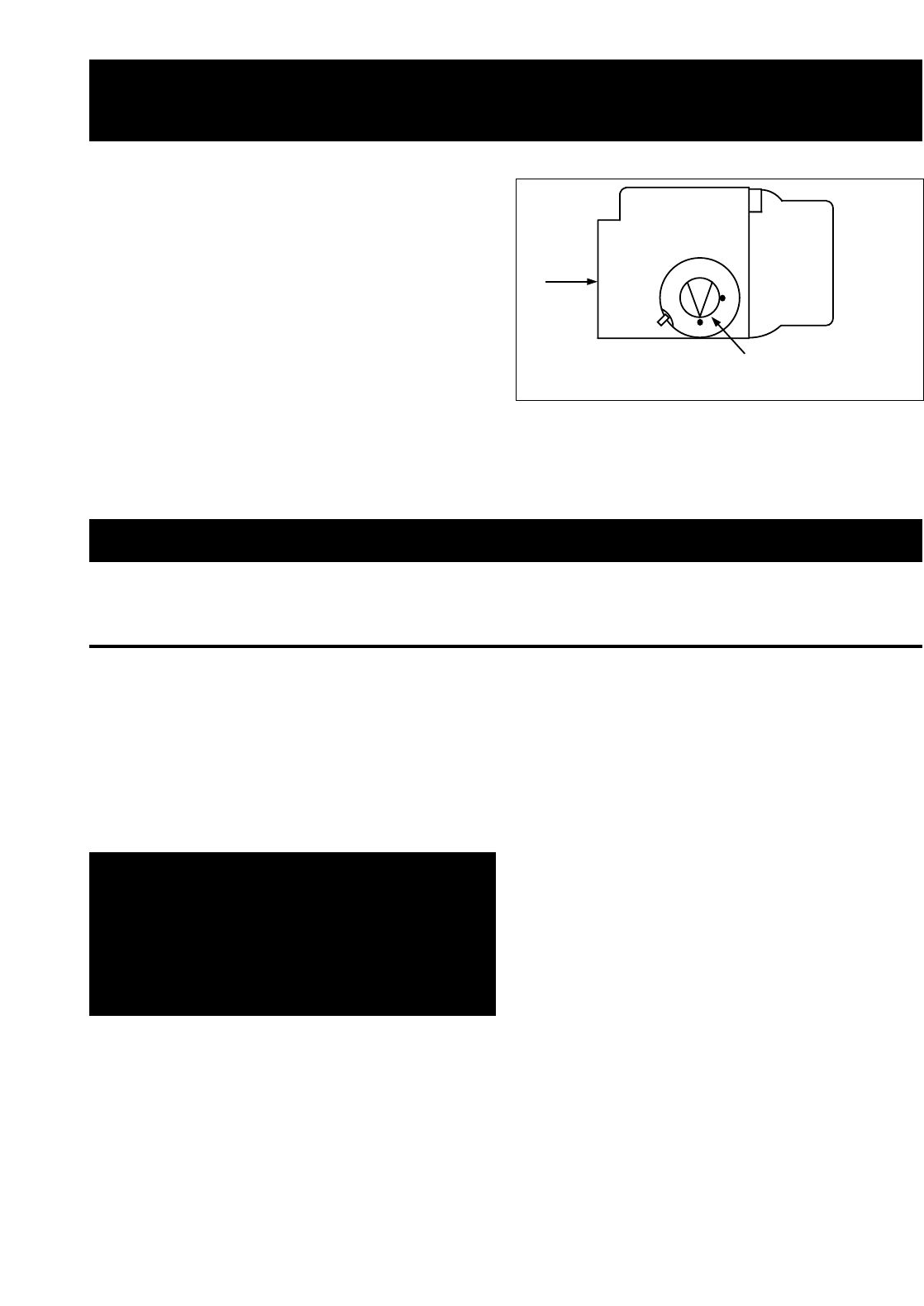

TO TURN OFF APPLIANCE

INLET

GAS CONTROL KNOB

SHOWN IN "OFF" POSITION

GAS

ON

OFF

INTERMITTENT PILOT - HONEYWELL VR8204

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance if service is to

be performed.

OPERATING INSTRUCTIONS

Intermittent Pilot - Honeywell VR8204

Natural or Propane Gas

1. STOP! Read the safety information on page 13..

2. Set the thermostat to lowest setting.

3. Turn off all electric power to the appliance.

4. This appliance is equipped with an ignition device which

automatically lights the pilot. Do not try to light the pilot

by hand.

5. Remove control access panel (if applicable).

6. Rotate gas control knob clockwise to “OFF”.

7. Wait five (5) minutes to clear out any gas. Then smell for

gas, including near the floor. If you then smell gas STOP!

Follow “A” on page 13. If you don’t smell gas, go to next

step.

8. Turn gas control knob counterclockwise to “ON”.

9. Replace control access panel (if applicable).

10. Turn on all electric power to the appliance.

11. Set thermostat to desired setting.

12. If the appliance will not operate, follow the instructions

"To Turn Off Appliance and call your service technician or

gas supplier.

3. Turn gas control knob counterclockwise to “OFF” Do not

force.

SECTION 4: MAINTENANCE

This boiler has been designed to provide years of trouble

free performance in normal installations. Examination by the

homeowner at the beginning of each heating season, and in

mid-heating season, should assure continued good perfor-

mance. In addition, the boiler should be examined by a quali-

fied service professional at least once every year.

NOTE: Do not draw water from heating system for clean-

ing. Minerals in the water can build up on the heat trans-

fer surfaces and cause overheating and subsequent fail-

ure of the cast iron sections.

NOTE: To reduce the risk of fouling, the low water cut-off

should be blown down at least once a week during heat-

ing season.

BEFORE EACH HEATING SEASON

1. Remove and inspect draft diverter and smoke pipe (con-

necting draft diverter to chimney or vent) for obstructions,

soot accumulation, rust or corrosion. Clean and replace as

necessary. Check tightness of joints; seal all joints where

necessary.

2. Check boiler flue passageways in the boiler sections for

any blockage or soot accumulation. Remove jacket top and

draft diverter. Using a flashlight, examine all flue passage-

ways.

a. If passageways are free of soot and obstructions, replace

draft diverter and seal with furnace cement.

b. If passageways need cleaning, remove flueway baffles

and burners as described in paragraph 3 below. Insert

long-handle bristle flue brush down between section

tubes and upward through sections from combustion

chamber in both diagonal directions to remove carbon

from finned surfaces. Vacuum debris. Replace the draft

diverter and seal with furnace cement.

c. Reinstall jacket top panel.

3. Check and clean burner assembly. Remove burner access

panel. Lift burners up and to rear until burners are disen-

gaged from orifices. Brush top of burners with soft bristle

brush and blow out with air or vacuum.

DANGER:To avoid fire and explosion hazards: Do not

store anything against the boiler or allow dirt or

debris to accumulate in the area immediately sur-

rounding the boiler. Keep boiler area clear and free

from combustible materials, gasoline and other

flammable vapors and liquids. Lint, paper or rags

must not be allowed to accumulate near the burners.

Do not place clothing on boiler casing to dry.