12

Example: A GB200-4L boiler takes 5 minutes, 27 seconds to

use 10 cubic feet of natural gas. The local utility indicated the

heating value of the natural gas being supplied is 1000

Btu/cu ft. Therefore:

5 minutes, 27 seconds = 327 seconds.

36,000

x 1000 = 110,000 Btu/hr

327

Therefore, the boiler input is correct.

NOTE: Before calculating the input of the heating equip-

ment, obtain the heating value of the gas from the local

utility.

7. If input needs to be corrected, adjust combination gas

valve pressure regulator. (Regulator is factory set at 3-

1/2" W.C. for natural gas and 10" W.C. for propane.) Turn

adjusting screw clockwise to increase gas flow (increase

input). Turn adjusting screw counterclockwise to

decrease gas flow (decrease input). In no case should

final manifold pressure setting vary more than + .3" from

factory-set pressures. If rated input cannot be obtained

with adjustment, gas supply pressure or orifice size may

be cause. Consult local utility and Smith.

8. Gas burner orifices supplied with boiler have been care-

fully designed to provide correct gas input rate for most

gas conditions typically found in the U.S. Occasionally,

however, local gas characteristics may not allow unit to

be properly adjusted for input. If this is the case, local

utility or Smith may recommend orifices be changed.

When changing orifices follow the procedures detailed in

Section 4 of this manual.

9. Start and stop burners several times by raising and low-

ering the thermostat setting.

10. After boiler has been firing long enough to raise boiler

pressure above minimum setting of the primary pressure-

tol limit, check limit by turning its setting from maximum

to minimum setting. This should turn boiler off. Return

limit to desired setting.

11. Check boiler safety shutoff controls.

For boilers with intermittent pilot, with boiler firing, discon-

nect wire connected to the "PV" terminal on the Honey-

well S8600 control. The gas valve should close.

For boilers with constant pilot, with boiler firing, turn the

gas control knob on the gas valve to “PILOT”. The burn-

ers should go out. Extinguish the pilot and wait 3 min-

utes. Turn the gas valve control knob to “ON”. There

should be NO gas flow to the main burners with the pilot

out! If gas flow is detected, immediately turn the gas

valve control knob to “OFF” and have the problem cor-

rected.

12. On initial start-up and prior to each heating season, boil-

er must be cleaned with a commercially available steam

boiler cleaner (see "Steam Boiler Cleaning Instructions"

in Section 4 of this manual).

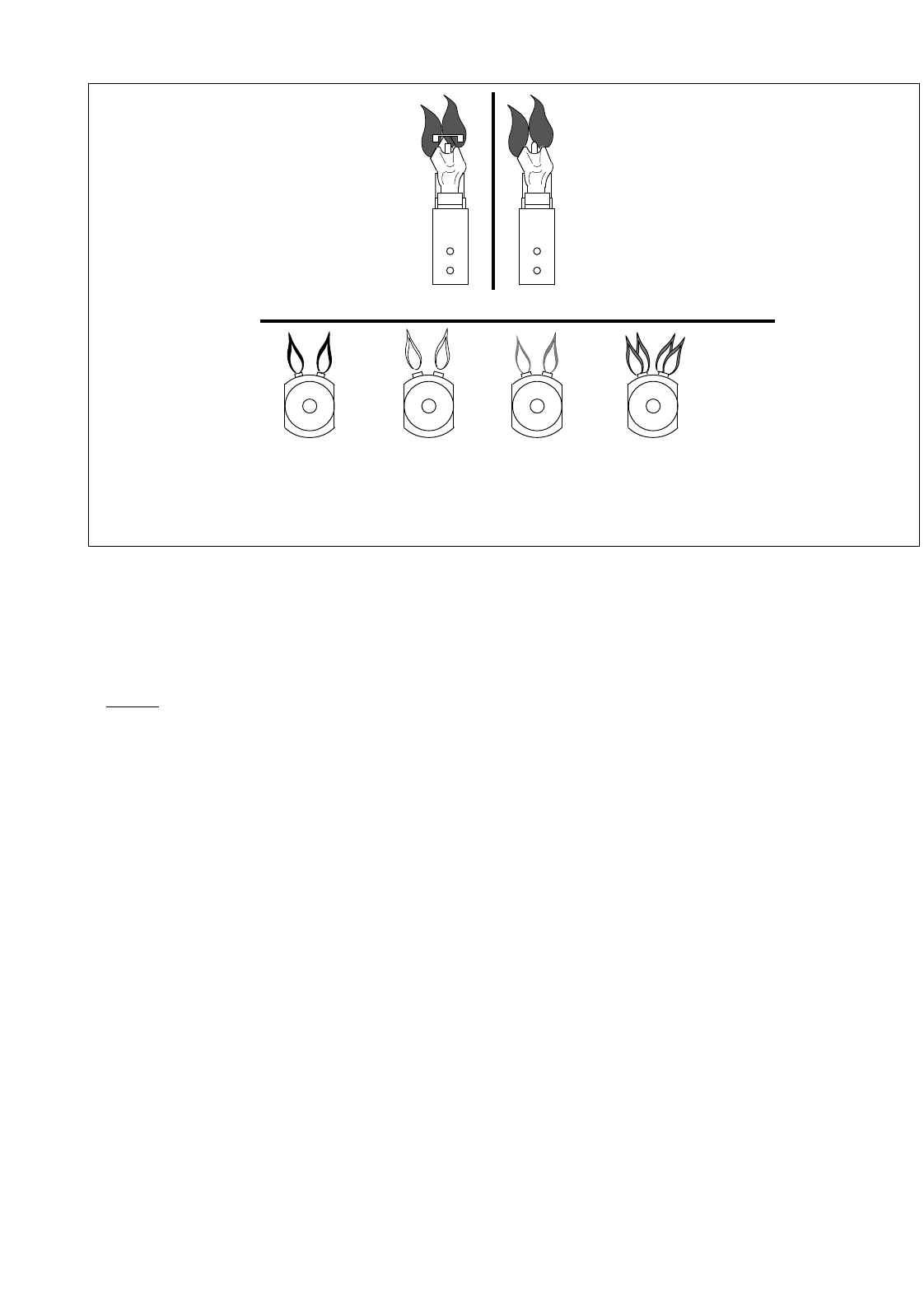

FIGURE 3.2: BURNER FLAME COMPARISON/PILOT FLAME

YELLOW

FLAME

(TOO LITTLE AIR)

YELLOW

TIPPING

(MARGINAL)

LIFTING

(TOO MUCH AIR)

NORMAL

(HARD FLAME)

NORMAL PILOT FLAME

MAIN BURNER FLAMES

Q314A/Q309A

CONSTANT PILOT

MODELS

Q3451B

INTERMITTENT

IGNITION PILOT

MODELS