1 In accordance with current CAN/CGA-B149 Installation Codes.

2 In accordance with current ANSI Z223.1/ NFPA 54 National Fuel Gas Code.

+ A vent shall not terminate directly above a sidewalk or paved driveway that is located between two single family dwellings and serves both dwellings.

* If clearances are not specified then follow local installation codes and the requirement of the gas supplier.

H = Clearance to each side of center line

extended meter/regulator assembly.

above

3 feet (91 cm) within a height 15 feet (4.57

m) above the meter/regulator assembly.

*

I = Clearance to service regulator vent

outlet.

3 feet (91 cm)

*

J = Clearance to nonmechanical air supply

inlet to the combustion air inlet to any

building or other appliance.

6 inches (15 cm) for appliances < 10,000

Btuh (3 kW), 12 inches (30 cm) for appli-

ances > 10,000 Btuh (3kW) and

< 100,000 Btuh (30kW), 36 inches (91 cm)

for appliances > 100,000 Btuh (30kW).

4 feet (1.2 m) below or to side of opening;

1 foot (300 mm) above opening.

K = Clearance to mechanical air supply

inlet.

6 feet (1.83 m) 3 feet (91 cm) above if within 10 feet

(3 m) horizontally.

L = Clearance above paved side walk or

paved driveway located on public

property.

7 feet (2.13 m) 7 feet (2.13 m)

M = Clearance under veranda, porch, deck

or balcony.

Not Allowed Not Allowed

Canadian Installations

1

US Installations

2

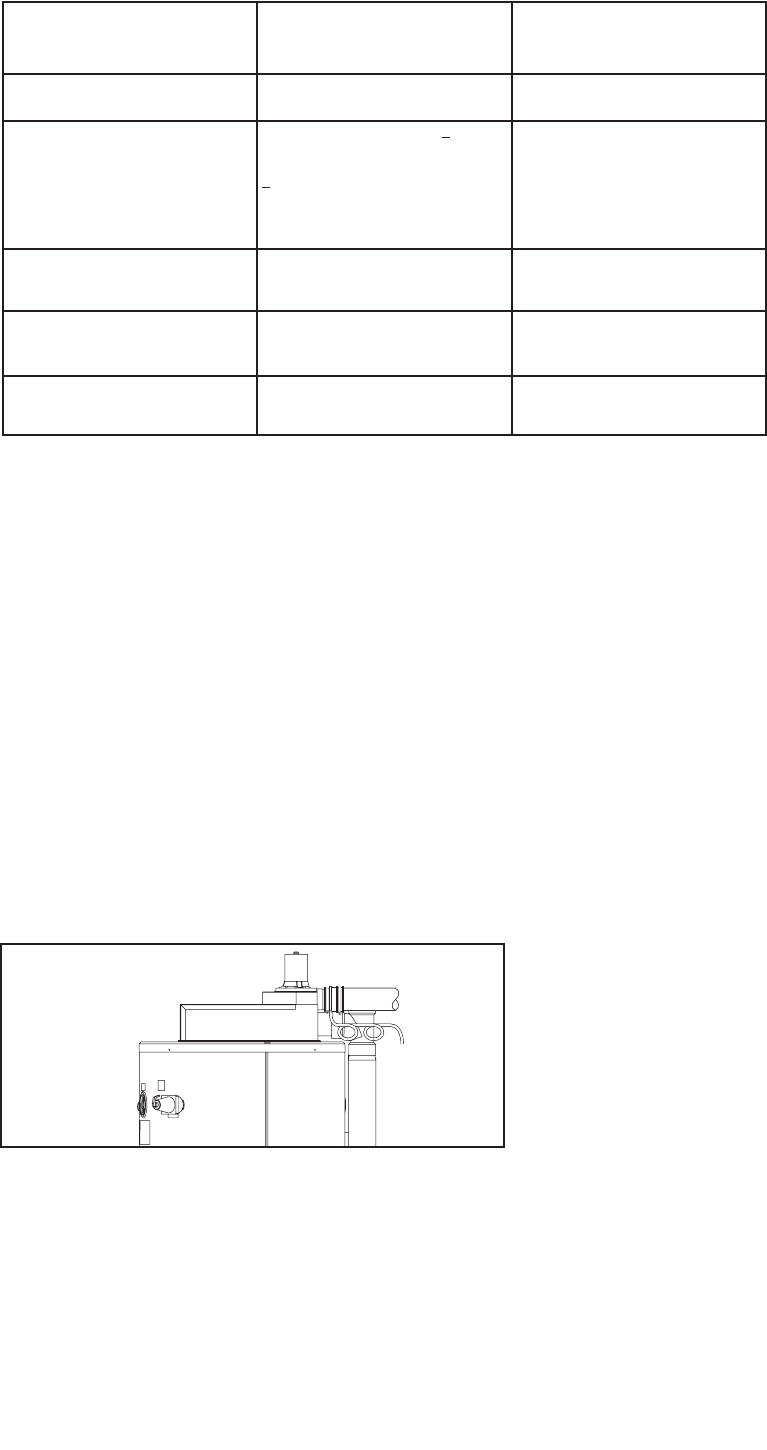

DRAINING THE CONDENSATE – In certain conditions,

installations in unconditioned space or having long horizontal or vertical

runs may accumulate condensate. In order to prevent condensate from

draining back into the blower, we recommend that it be drained. This

unit is provided with a special fitting on the blower that allows for the

draining of condensate formed in the vent. The drain hose should have

two (2) loops formed, to act as traps. Before operation of the water

heater, both loops should have water placed in them. Support the traps

so that they remain horizontal. Condensate is known to be acidic; refer

to local, state or federal codes for proper handling methods.

JOINING PIPES AND FITTINGS – All pipe, fittings, solvent

cement, primers and procedures must conform to Ameri-

can National Standards Institute and American Society for

Testing and Materials (ANSI/ASTM) standards.

CEMENTING JOINTS – All joints in the vent piping must

be properly sealed and we recommend using the following mate-

rial:

PVC materials should use ASTM D-2564 grade cement.

CPVC materials should use ASTM F-493 grade cement.

ABS materials should use ASTM D-2235 grade cement.

Cleaner-Primer and Medium Body Solvent Cement

1. Cut pipe end square, remove jagged edges and burrs. Cham

-

fer end of pipe, then clean fitting socket and pipe joint area

of all dirt, grease or moisture.

2. After checking pipe and socket for proper fit, wipe

socket and pipe with cleaner-primer. Apply a liberal coat of

primer to inside surface of socket and outside of pipe. Do not

allow primer to dry before applying cement.

3. Apply a thin coat of cement evenly in the socket. Quickly

apply a heavy coat of cement to the pipe end and in-

sert pipe into fitting with a slight twisting motion until it

bottoms out.

NOTICE: Cement must be fluid; if not, recoat.

4. Hold the pipe fitting for 30 seconds to prevent the tapered

socket from pushing the pipe out of the fitting.

5. Wipe all excess cement from the joint with a rag. Allow 15

minutes before handling. Cure time will vary according to fit,

temperature and humidity.

NOTICE: Stir the solvent cement frequently while using. Use

a natural bristle brush or the dauber supplied with the can.

The proper brush size is one inch.

Figure 10 - Draining the Condensate

12