Regency

®

P121-2/P121LC-2/P121RC-2/P131-2 Zero Clearance Direct Vent Gas Fireplace 21

INSTALLATION

HORIZONTAL

TERMINATIONS

Install the vent system according to the

manufacturer's instructions included with

the components.

1) Set the unit in its desired location. Check

to determine if wall studs or roof rafters

are in the way when the venting system is

attached. If this is the case, you may want

to adjust the location of the unit. Rough in

the gas.

2) Direct Vent pipe and fi ttings are designed

with special twist-lock connections to

connect the venting system to the appliance

fl ue outlet. A twist-lock appliance adaptor

is an available option that must be used in

conjunction with the Simpson Dura-Vent

Direct Vent GS system.

3) Put a bead of silicone inside the outer

section of the adapter and a bead of Mill

Pac on the inner collar. Slip the adapter

over the existing inner and outer fl ue collar

and fasten to the outer collar only with the

3 supplied screws (drilling pilot holes will

make this easier). Level the fi replace and

fasten it to the framing using nails or screws

through the nailing strips.

4) Assemble the desired combination of pipe

and elbows to the appliance adaptor and

twist-lock for a solid connection.

Note:

a) Twist-lock procedure: Four indentations,

located on the female ends of pipes and

fi ttings, are designed to slide straight

onto the male ends of adjacent pipes

and fi ttings, by orienting the four pipe

indentations so they match and slide

in to the four entry slots on the male

Diagram 1

Diagram 2

Note:

a) The horizontal run of vent must be level,

or have a 1/4 inch rise for every 1 foot

of run towards the termination. Never

allow the vent to run downward. This

could cause high temperatures and

may present the possibility of a fi re.

b) The location of the horizontal vent

termination on an exterior wall must

meet all local and national building

codes, and must not be blocked or

obstructed. For External Vent Terminal

Locations, see diagram in the "Exterior

Vent Termination Locations" section.

6) The arrow on the vent cap should

be pointing up. Insure that the 1-1/2"

clearances to combustible materials are

maintained (Diagram 3 in the "Venting

Arrangement - Horizontal Terminations"

section) Install the termination cap.

The four wood screws provided should

be replaced with appropriate fasteners for

stucco, brick, concrete, or other types of

sidings.

Note: If installing termination on a siding

covered wall, a vinyl siding standoff

or furring strips must be used to

ensure that the termination is not

recessed into the siding.

Note: Apply sealant "Mill-Pac" to inner

pipe and high temperature silicone

sealant to outer pipe on every twist-

lock joint.

b) Horizontal runs of vent must be

supported every three feet. Wall straps

are available for this purpose.

5) Mark the wall for a 10" x 10" square hole.

The center of the square hole should line

up with the centerline of the horizontal pipe.

Cut and frame the 10 inch square hole in

the exterior wall where the vent will be

terminated. If the wall being penetrated is

constructed of non-combustible material, i.e.

masonry block or concrete, a 7"(178mm)

dia. (7-1/2"(191mm) dia. for fl ex) hole is

acceptable.

Note: With Dura-Vent, the minimum height

is achieved by installing a 45

o

elbow directly

to the rigid pipe adaptor.

Diagram 12

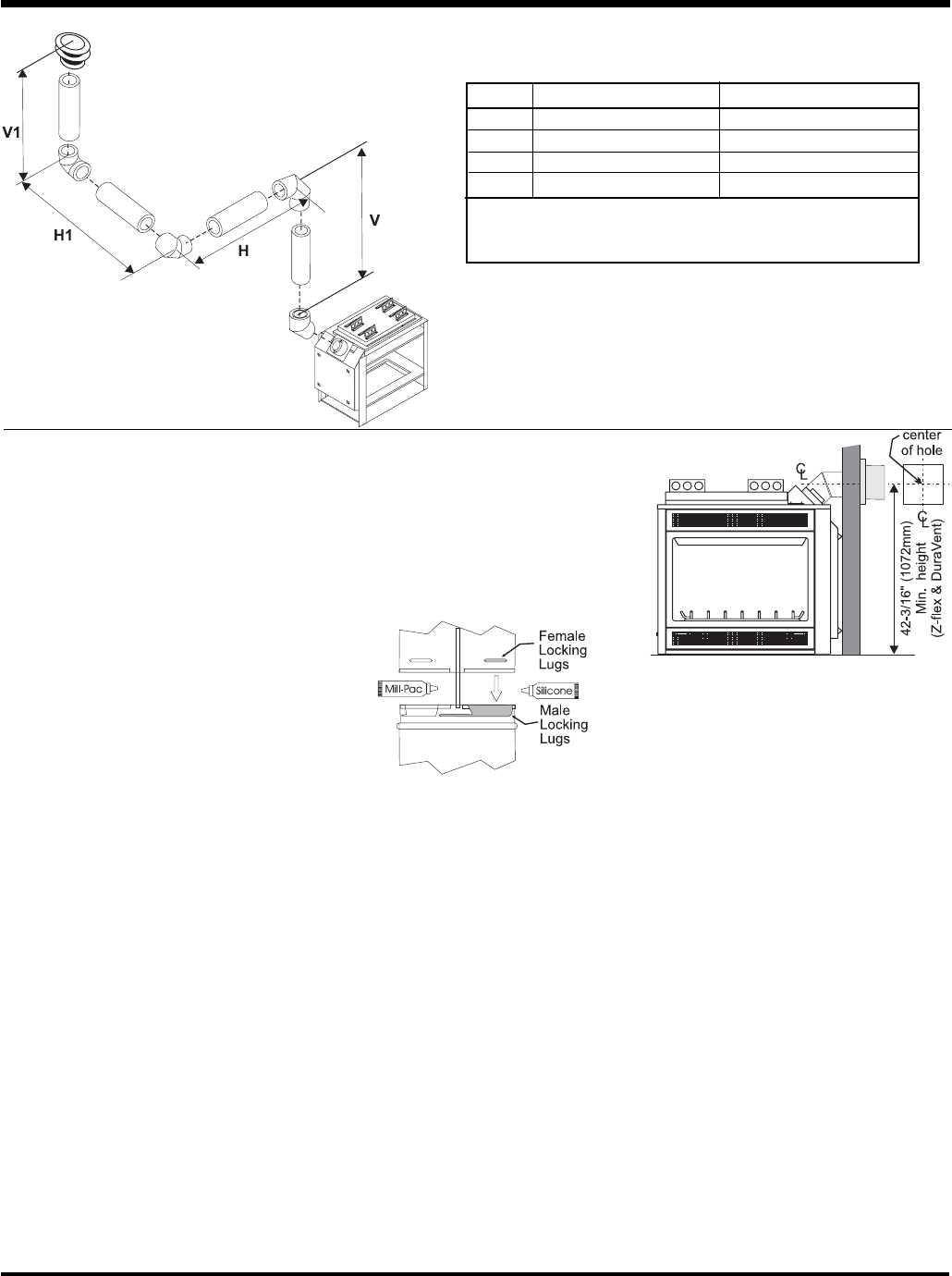

Vertical Venting with Three (3) 90

o

Elbows

ends, Diagram 1. Push the pipe sections

completely together, then twist-lock

one section clockwise approximately

one-quarter turn, until the two sections

are fully locked. The female locking lugs

will not be visible from the outside, on

the Black Pipe or fi ttings. They may be

located by examining the inside of the

female ends.

Option V + V1 H + H1

A) 2' (610mm) Minimum 3' (914mm) Maximum

B) 3' (914mm) Minimum 6' (1.86m) Maximum

C) 4' (1.22m) Minimum 9' (2.7m) Maximum

D) 5' (1.5m) Minimum 12' (3.6m) Maximum

With the above options, maximum total pipe length if 37 feet with minimum

of 5 feet total vertical and maximum 12 feet total horizontal.

Please note minimum 1 foot between 90

o

elbows is required.