IGNITION CONTROL MODULE

The interrupted proved ignition device conserves energy. When additional heat

is needed, the combustion air blower starts to purge all air from the combustion

chamber for about 15 seconds. On proof of air flow, the air proving switch closes

and the igniter is energized, eliminating the fuel costs of maintaining a constant

pilot. To assure safe operation, the gas valve cannot open until the pilot igniter is

verified. The 100% igniter safety is an electronic device which closes the main gas

valve within 8/10 of a second whenever the flame is interrupted. Main burner is

automatically lit when the device is powered and pre-purged. Unit performs its

own safety check and opens the main valve only after the igniter is proven to be

capable of ignition.

HIGH LIMIT (MANUAL RESET)

The boiler is equipped with a manual reset high limit temperature device. Push the

reset button and adjust the setting to 30° F or 40° F above desired operating

temperature.

FLOW SWITCH

Dual-purpose control shuts off boiler in case of pump failure or low water flow.

Mounted and wired in series with the main gas valve. Check with Manufacturer for

proper paddle size. Utilize correct paddle size for proper operation.

NOTICE: Flow switch will not operate if flow is less than 20 GPM.

OPERATING CONTROL

The heater may be equipped with different types of operating controls. Consult

data sheet supplied with installation instructions. See Section L for adjustment

safety precautions on domestic hot water applications.

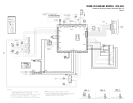

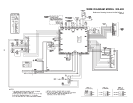

IGNITION MODULE

Fig. J-3

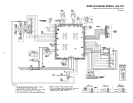

MANUAL RESET HIGH LIMIT

Fig. J-4

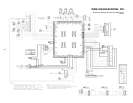

FLOW SWITCH

THERMOSTAT CONTROL

47

Drw. #8644

Drw. #8241

Drw. #8643

Fig #9322