44

HI-DELTA Model 302-402

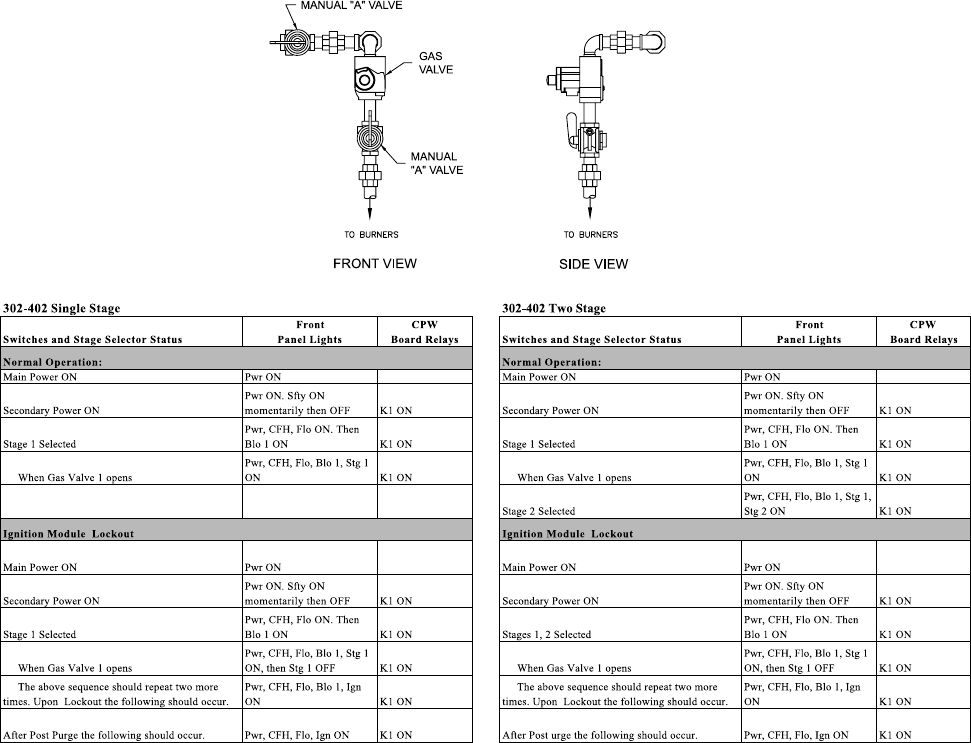

The black (hot) wire leads you directly to the Main Power Switch. This switch is located at the bottom right-front corner of

the control compartment. When the main power switch is placed in the “ON” position, both the 120 v and 24 v terminal blocks

on the Main Circuit Board will be powered and the power light will turn on. When the Auto On- Off switch is turned ON, the

following 24 v safety components are immediately energized: Low Water Cut-off, Blocked Vent Switch, Manual Reset Limit

Control, Low Gas Pressure Switch (optional) and the High Gas Pressure Switch (optional). At this point if all the preceding

safety switches are closed, then Relay K. 1 (n.c.) will be energized and the safety light will turn off. The boiler is now ready

for a call for heat.

When STAGE 1 calls for heat, the CALL FOR HEAT LIGHT will turn on. The Economaster Board will be energized and the

pump will turn on. If the pump generates enough flow to activate the flow switch, the flow light would turn on, then power will

be applied to the thermostat terminal of the Ignition Module and the Blower will activate. The Air Pressure Switch would then

close and the pressure switch terminal on the Ignition Module will be energized, the blower light will turn on. The Unit will

now undergo a 15 second pre-purge. After the pre-purge cycle, Hot Surface Igniter will heat up. The heat-up period takes

about 30 seconds after which a trial for ignition is initiated. During the trial for ignition, which lasts for four seconds, power

is applied to Firing Valve No. 1. If within four seconds, the Remote Sensor establishes flame rectification, Firing Valve No. 1

stays open and the Stage 1 light will turn on. Also, the Valve terminal from the Ignition Module will power Relay K2.

When Stage 2 calls for heat, power will be applied to Firing Valve No. 2 (Solenoid Gas Valve located on the lower manifold),

and the Stage 2 light will turn on.

Boiler Sequence of Operations