MAYCO ST-45HRM CE PUMP — OPERATION & PARTS MANUAL — REV. #0 (02/23/04) — PAGE 41

3.0 BRAKING SYSTEM

3.1 WHEEL JACKING

On level ground, with the hand brake lever in the off position and

overrun coupling draw tube shaft fully extended forwards, secure

one wheel with wheel chocks. Position your jacking device behind

the opposite wheel, as near to a main longitudinal chassis

member as possible. Lift the wheel clear of the ground and secure

with suitable axle stands.

3.2 BRAKING SYSTEM ADJUSTMENT

Where the transmission rod and brake cables are already

connected, take the tension out of the system by winding back

the nuts on the rod behind the compensator.

It is now possible to begin the setup procedure:

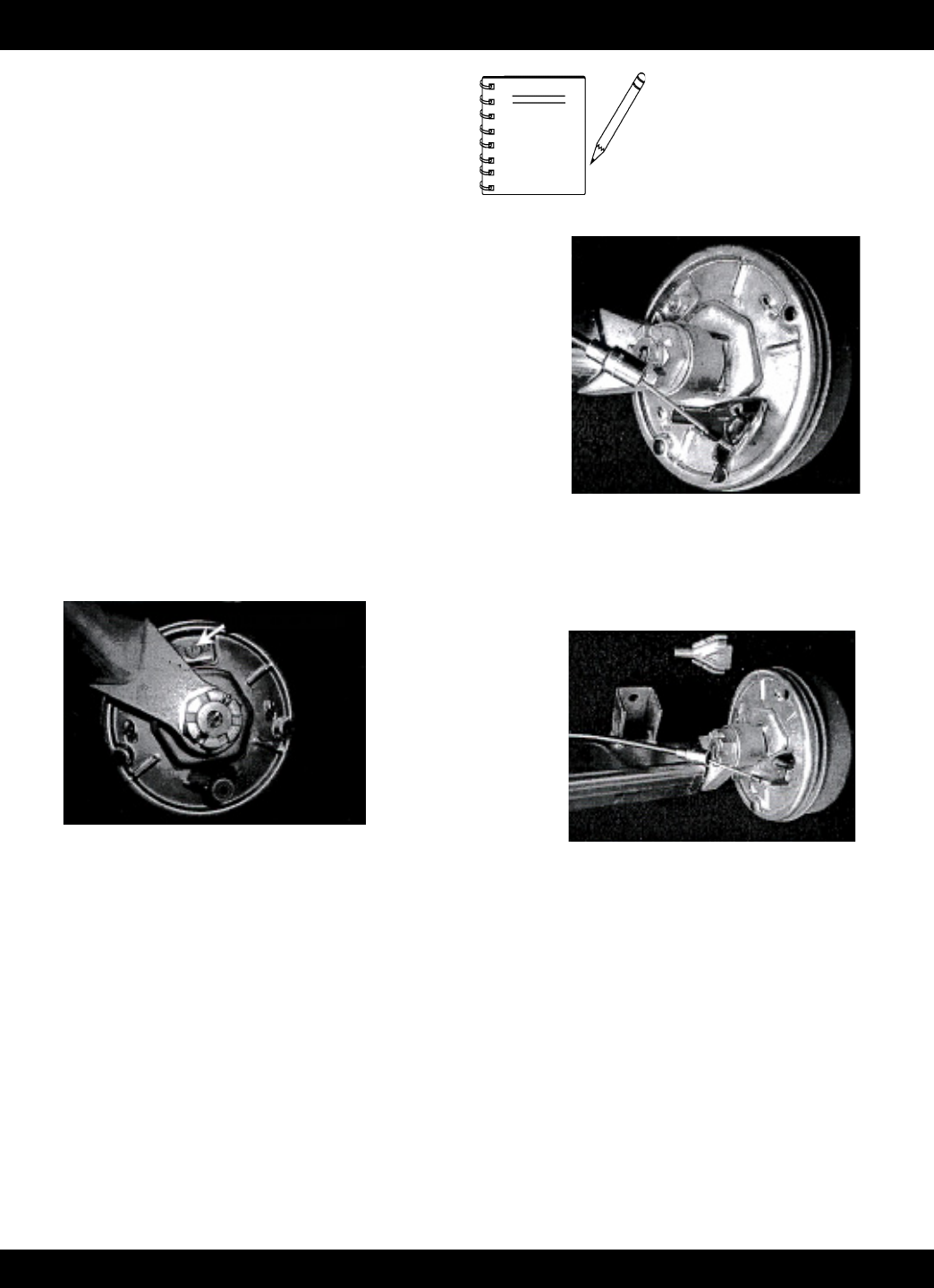

3.3 WHEEL BRAKES

These can be adjusted by means of a 17mm, 19mm, or 24mm

AF Spanner (dependant on brake type) on the adjuster bolt head

at the rear of the brake back plate. Reference Figures 40A, B

and C.

Adjuster Bolt

Rotate each wheel only in the forward direction of travel, whilst

tightening the bolt until the wheel locks. Then, gradually back off

the adjuster nut until the wheel can rotate forwards with just a

slight resistance/audible brushing of the brake drum on the brake

linings (this is best adjusted with the wheel and tyre fitted to the

brake drum).

Figure 40A. Adjuster Bolt

Figure 40B. Connecting Sheated Cable

Figure 40C. Connecting Sheated Cable

NOTE

If not already connected, connect the

Bowden (sheathed) cables to the

brakes.

ST-45HRM CE CONCRETE PUMP— BRAKING SYSTEM