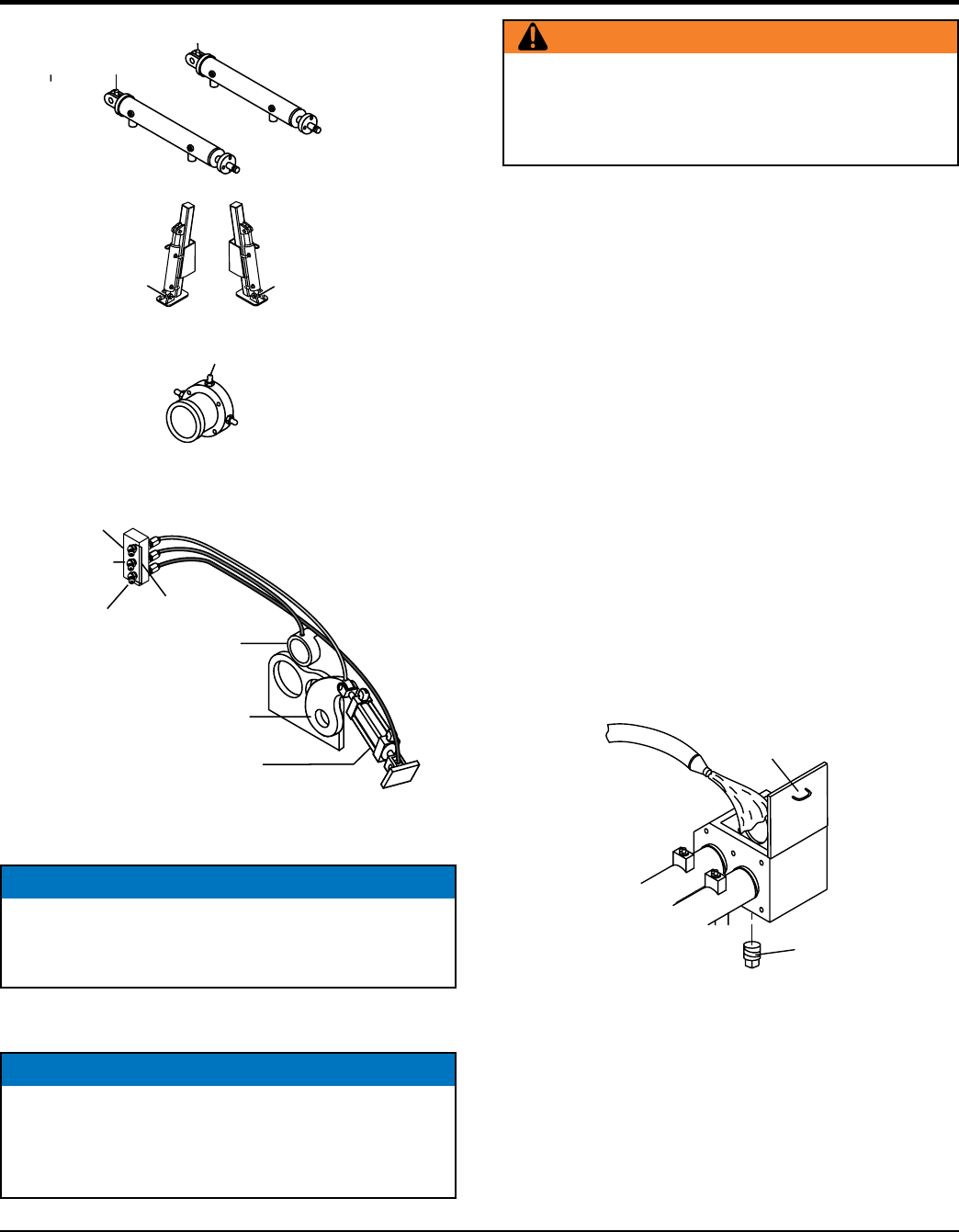

Figure 53. Lubrication Points

Cylinder Lubrication Box

OUTRIGGERS

LEFT

RIGHT

SWINGAXLE

BUSHING

SHUTTLE

CYLINDER

AXLE

CRANK

GREASE

POINTS

SHUTTLE

CYLINDER

TOP

SHUTTLE

CYLINDER

BOTTOM

SWINGAXLE

DISCHARGE

NIPPLE

GREASE

POINTS (3)

GREASE

POINT

GREASE

POINT

CYLINDER

“B”

CYLINDER

“A”

GREASE

POINT

GREASE

POINT

NOTICE

When lubricating the above components, use Lithium

Based EP, Texaco Multitak 20 or Lubriplate ED-2 type

grease.

NOTICE

When using the pump during freezing conditions,

completely drain the lubrication box and cover the hopper

after pumping. Frozen liquid will restrict the piston travel

and cause severe damage to the pump.

MAINTENANCE

1. The lubrication level should be checked everyday prior

to pumping and maintained at a height of 5 inches or

about ½ the concrete cylinder height. We recommend

using a 30-weight motor oil.

2. As the rubber piston cups naturally wear, fine cement

particles will accumulate in the box. Once the concrete

paste reaches a height of about ½ inch from the bottom

of the box, drain and clean the lubrication box.

Cleaning the Lubrication Box

1. Remove the top cover and the drain plug (Figure 54)

located at the bottom of the box and fully drain the

inside of the box.

2. Once the box is drained, start the engine and stroke

the cylinder (keep hands out of box) ten to fifteen times.

3. While stroking, spray water inside of the box to

thoroughly clean out all contamination (Figure 54).

4. When the box is clean replace drain plug, add new

lubrication and install the top cover.

Figure 54. Cleaning the Lubrication Box

ALWAYS follow lock out-tag out procedures before

checking lubrication level, Stop the engine and remove

the engine starter key. The possibility exists of severe

bodily harm when hands are placed inside.

DRAIN

PLUG

TOP

COVER

W

A

T

E

R