Prior to each use, the pump should be cleaned and

inspected for deficiencies. Check for loose, missing or

damaged nuts, bolts or other fasteners. Also check for

fuel, oil, and coolant leaks. Use Table 5 as a general

maintenance guideline Engine Side (Refer to the Engine

Instruction Manual)

Certain maintenance operations or machineadjustments

require specialized knowledge and skill. Attempting

to perform maintenance operations or adjustments

without the proper knowledge, skills or training could

result in equipment damage or injury to personnel. If

in doubt, consult your dealer.

Accidental starts can cause severe injury

or death.

ALWAYS place the ON/OFF switch in the

OFF position.

Disconnect and ground spark plug leads

and disconnect negative battery cable

from battery before servicing.

Some maintenance operations may

require the engine to be run. Ensure

that the maintenance area is well

ventilated. Exhaust contains poisonous

carbon monoxide gas that can cause

unconsciousness and may result in

DEATH

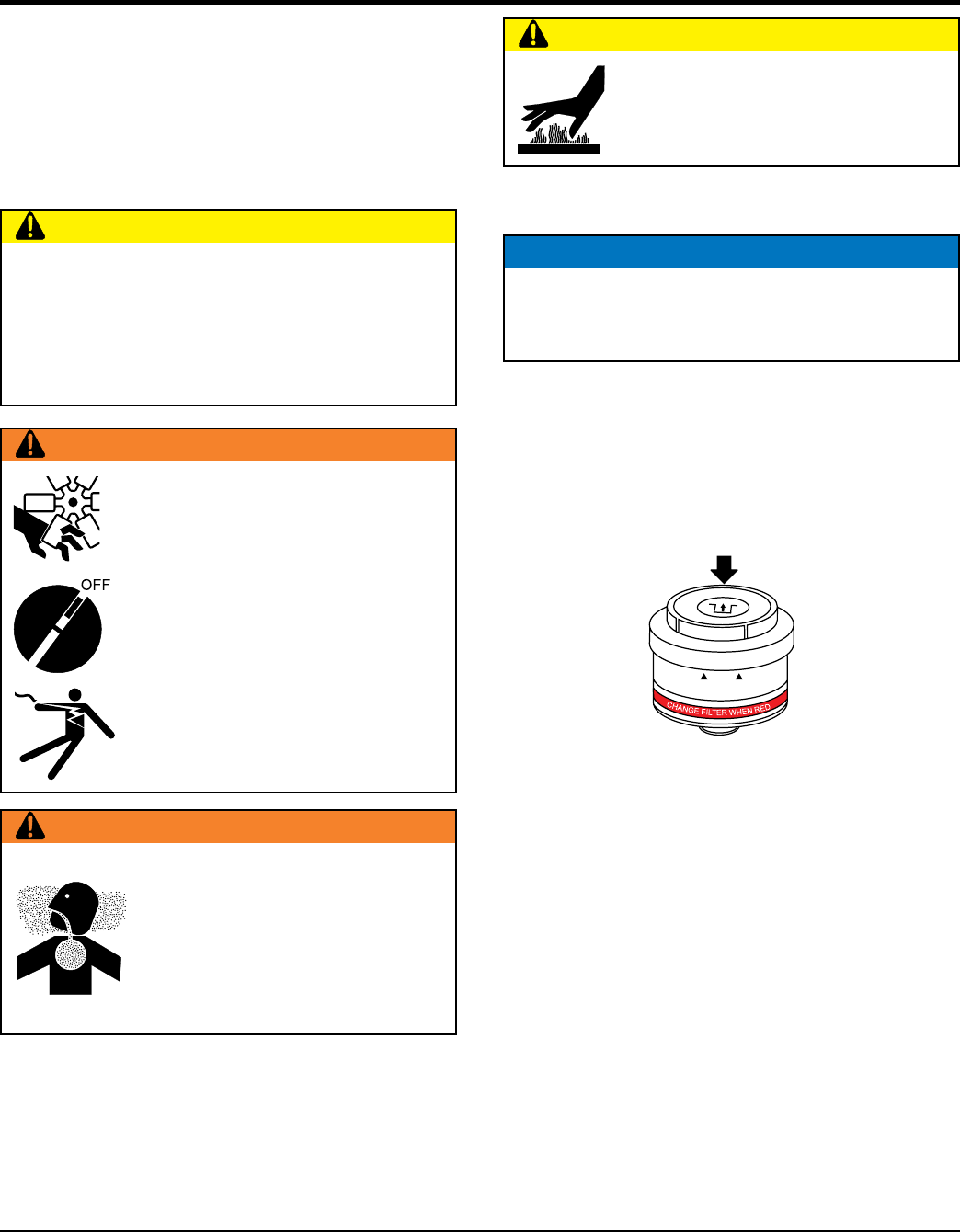

This indicator (Figure 41) is attached to the air cleaner.

When the air cleaner element is clogged, air intake

restriction becomes greater and the dust indicator signal

shows RED meaning the element needs changing or

service. After changing the air element, press the dust

indicator button to reset the indicator.

Figure 41. Air Cleaner Service Indicator

ALWAYS allow the engine to cool

before servicing. NEVER attempt any

maintenance work on a hot engine.

NOTICE

The air filter should not be changed until the indicator

reads “RED”. Dispose of old air filter. It may not be

cleaned or reused.

RESET

AIR FILTER INDICATOR

PUSH CENTER TO

RESET

5 KPA

MAINTENANCE