6G7 ENGINE (E-W) -

Piston and Connecting Rod

11A-12-3

INSPECTION

PISTON RING

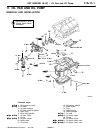

(1) Check the clearance between the piston ring and the ring

groove. If it exceeds the specified limit, change the ring

or the piston and piston ring.

Standard values: No. 1 0.03 - 0.07 mm

No. 2 0.02 - 0.06 mm

Limit: 0.1 mm

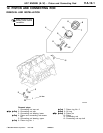

(2) Place the piston ring in the cylinder bore, push it in by

applying the piston head side, and make sure it is square.

Then measure the clearance at the ring ends with a

thickness gauge.

Change the piston ring if the clearance at the ring end

is excessive.

Standard values: No. 1 0.30 - 0.45 mm

No. 2 0.45 - 0.60 mm

Oil 0.20 - 0.60 mm

Limit: No. 1 0.8 mm

No. 2 0.8 mm

Oil 1.0 mm

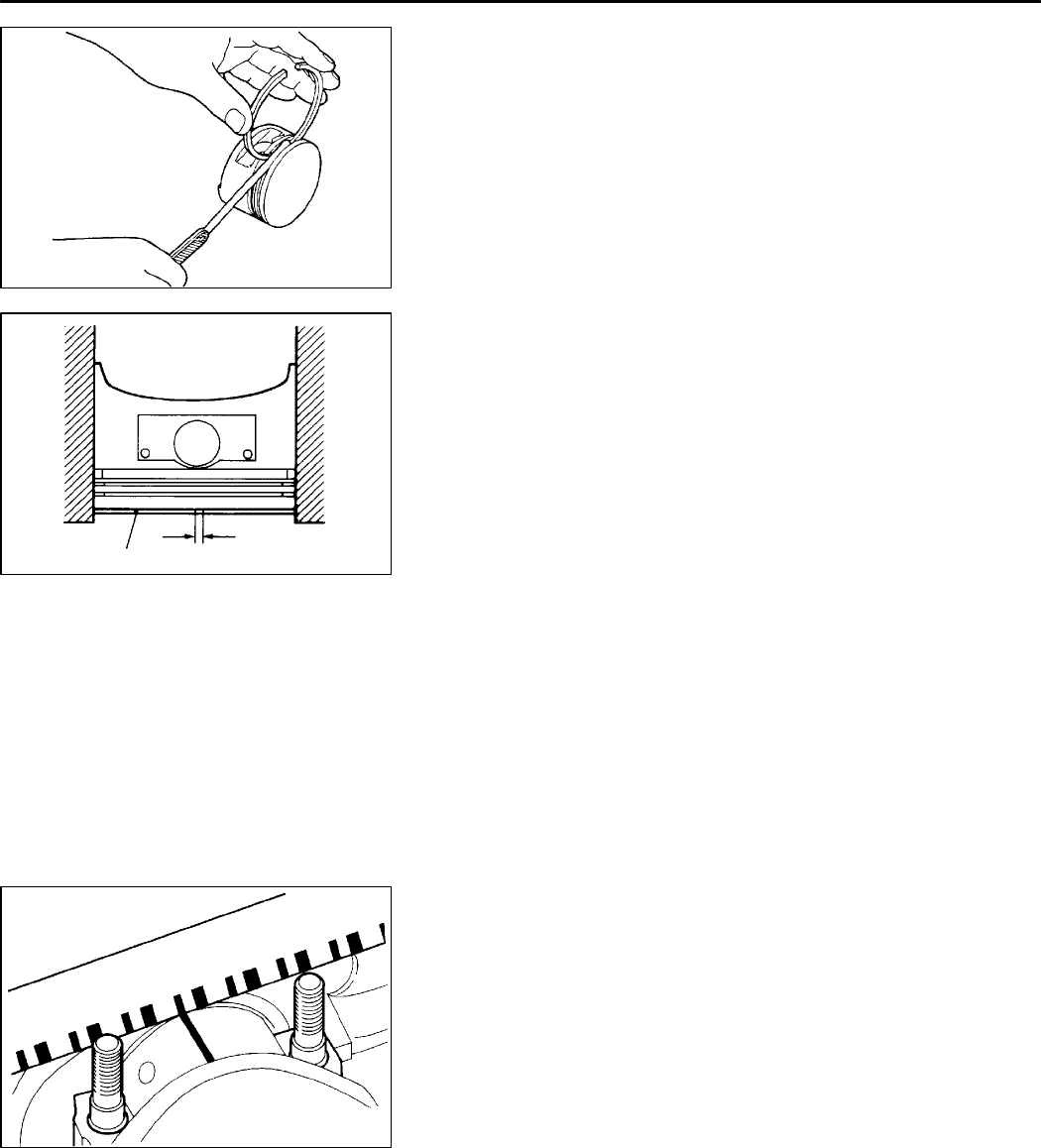

CRANKSHAFT PIN OIL CLEARANCE (PLASTIGAUGE

METHOD)

(1) Drain oil from the crankshaft pin and the connecting rod

bearing.

(2) Place a piece of Plastigauge the length of the bearing

width on the crankshaft pin straight along the pin centre.

(3) Gently place the connecting rod cap on top and tighten

the bolt to the specified torque.

(4) Detach the bolt and gently remove the connecting rod

cap.

(5) Measurethe widthofthecrushedPlastigauge (atthewidest

point) using the scale printed on the Plastigauge package.

Standard value: 0.02 - 0.05 mm

Limit: 0.1 mm

PWEE9615

E

Dec. 1996Mitsubishi Motors Corporation

7EN0475

7EN0476

Push inusing

the piston

Piston ring

End clearance

1EN0246