6G7 ENGINE (E-W) -

Cylinder Head and Valves

11A-10-4

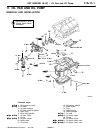

VALVE GUIDE

(1) Measure the clearance between the valve guide and the

valve stem. When the clearance exceeds the specified

limit, change the valve guide or the valve or both.

Standard value: Intake 0.02 - 0.04 mm

Exhaust 0.04 - 0.06 mm

Limit: Intake 0.10 mm

Exhaust 0.15 mm

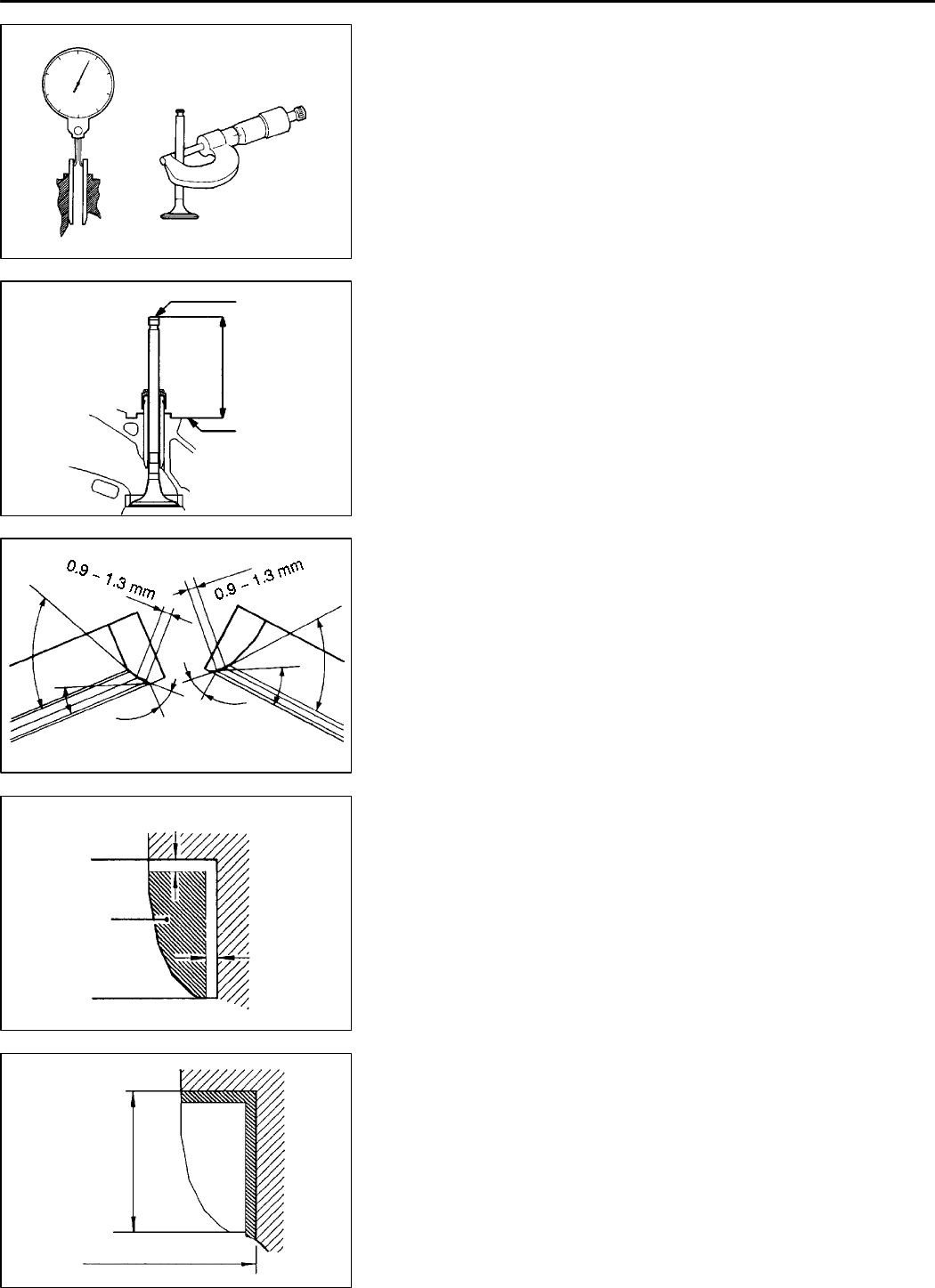

VALVE SEAT

(1) Assemble the valve, and with it pressed down on the

valve seat measure the part of the valve which protrudes

from the spring seat surface. The length measured should

be between the spring seat surface and the valve stem

end. If the measured value exceeds the limit, change the

valve.

Standard value: 49.3 mm

Limit: 49.8 mm

VALVE SEAT RECONDITIONING PROCEDURE

(1) Check the clearance between the valve guide and the

valve, and if necessary, change the valve guide before

correcting the valve seat.

(2) Correct so that the valve seat width and angle are as

specified in the figure at left.

(3) After making the corrections, apply lapping compound

and adjust the valve and valve seat.

VALVE SEAT REPLACEMENT PROCEDURE

(1) Cut off the inside of the valve seat to reduce its thickness

before pulling out the valve seat.

(2) Adjust the valve cylinder hole in the cylinder head to the

diameter of the oversize valve seat to be press fitted.

Intake valve seat hole diameter

0.30 O.S. 34.30 - 34.33 mm

0.60 O.S. 34.60 - 34.63 mm

Exhaust valve seat hole diameter

0.30 O.S. 31.80 - 31.83 mm

0.60 O.S. 32.10 - 32.13 mm

(3) When press fitting a valve seat, cool it using liquid nitrogen

so as not to gall the cylinder head inside diameter.

(4) Machine the valve seat.

(5) See “Valve seat reconditioning procedure.”

PWEE9615

E

Dec. 1996Mitsubishi Motors Corporation

1EN0279

Stem outside diameter

Guide inside diameter

DEN0212

Valve stem

end

Valve

protrusion

Spring seat

surface

7EN0273

65

_

15

_

44

_

44

_

65

_

25

_

1EN0274

Cut off

0.5 - 1 mm

0.5 - 1 mm

1EN0275

Height of

valve seat

Oversize hole diameter