8

7-3. Connecting the Sensors

•

For channel 1, select one of the following four types: Pt100 detection, 4 to 20 mADC, 1 to 5 VDC, or 0 to 10 VDC analog

input.

• For channel 2, select one of the following three types: 4 to 20 mADC, 1 to 5 VDC, or 0 to 10 VDC analog input.

• The wire length depends on the specifications of the sensor. However, since the use of long wires makes the device

susceptible to noise, using wires shorter than 12 m (39.4 ft) is recommended. Use a shielded line for the sensor line

and connect to the FG terminal on this unit or the FG terminal on the control panel.

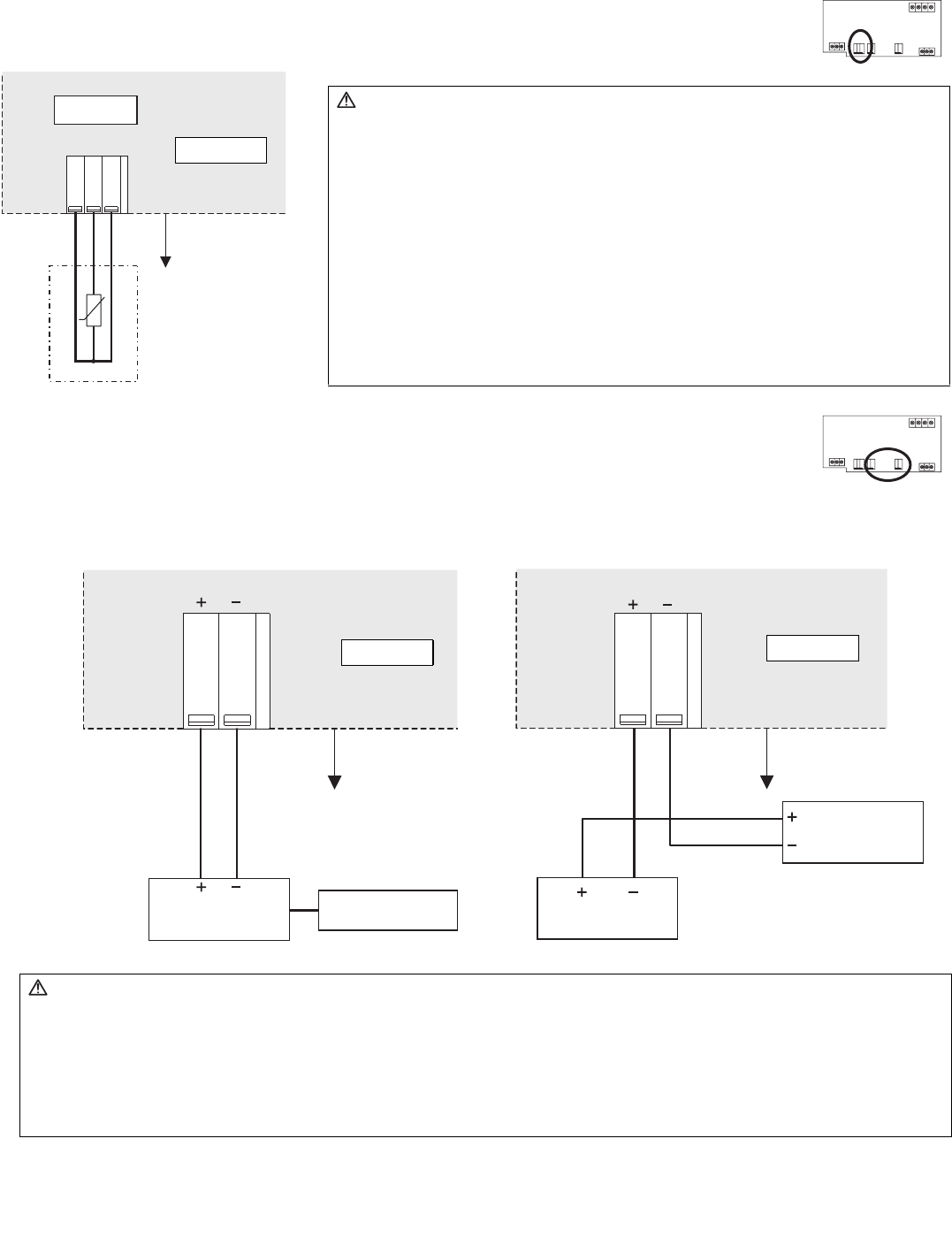

(1) Channel 1 Pt100 Input

To use these, various settings need to be configured. Refer to "8. Initial Settings".

(2) Channel 1 (Channel 2) Analog Input

To use these, various settings need to be configured.

Refer to "8. Initial Settings".

B /

BBA

A / B

CN10

t°

Caution:

• Use a 3-wire system for Pt100.

• A/B polarity is important for Pt100.

Be sure to match the polarity when using Pt100.

• Do not install the sensor input line parallel to or near the M-NET transmission

line or power line.

Also avoid loop wiring.

Furthermore, confirm the precautions for the sensor.

• Strip 12±1 mm (

15

/32 ±

1

/32 in) of the wire coating and insert firmly into the

terminal.

• Make sure that the copper wiring is not short-circuiting the plates (cover, lower

case) or neighboring wires.

• Perform wiring so that the terminal block is not strained.

If strained, use a wire guide or junction terminal to alleviate the stress on the

terminal block.

Pt100 (3-wire system)

Field

Connections

Device side

(4 to 20 mADC, 1 to 5 VDC, 0 to 10 VDC)

CN05

(CN08)

CN05

(CN08)

(a) When 1 to 5 VDC, 0 to 10 VDC, or 4 to 20 mADC

(type for which power is supplied to the sensor)

is connected

Field

Connections

Power supply

Sensor

Sensor

Power supply

(b) When 4 to 20 mADC (type for which power is

supplied to the signal line) is connected

Device side

Field

Connections

Device side

Caution:

• Select a power supply that is suitable for the sensor to be used.

• Do not install the sensor input line parallel to or near the M-NET transmission line or power line. Also avoid loop wiring.

Furthermore, confirm the precautions for the sensor.

• Strip 12±1 mm (

15

/32 ±

1

/32 in) of the wire coating and insert firmly into the terminal.

• Make sure that the copper wiring is not short-circuiting the plates (cover, lower case) or neighboring wires.

• Perform wiring so that the terminal block is not strained.

If strained, use a wire guide or junction terminal to alleviate the stress on the terminal block.