882108-YIM-B-1012

84 Johnson Controls Unitary Products

On an annual basis, check the motor for accumulations of

dust, etc. That may block the cooling slots in the motor shell.

Check for loose, damaged or misaligned drive components.

Check that all mounting bolts are tight. Replace defective

parts as required.

If desired, every three years remove both pipe plugs at each

end shell and clean out any hardened grease or foreign mat-

ter. Replace one plug on each end with a clean grease fitting.

Using a low pressure grease gun, pump grease (Chevron

SRI-2 or equivalent) into the bearing cavity until new grease

shows at the open port. Do not over-lubricate. Run the motor

for ten minutes until excess grease is purged from the cavity.

Replace the plugs.

FAN DRIVES

Units are supplied with fan shaft bearings that do not require

maintenance but may be relubricated per Table 59.

Lubricate with a premium quality NLGI 2 grade multi-purpose

roller bearing grease having corrosion inhibitors, anti-oxidant

additives and mechanical stability for high speed operation.

The grease should also have a minimum base oil viscosity of

500 SUS at 100°F. Do not use a heavy, long fibered grease.

The presents of dirt, moisture or chemical fumes around the

bearings requires more frequent lubrication.

Fill bearings with lubricant prior to extended shutdown or stor-

age. Rotate the shaft monthly during idle periods.

Avoid excessive grease purging from seals during lubrication,

this reduces the life of the bearing.

OUTDOOR COIL

Dirt should not be allowed to accumulate on the outdoor coil

surface or other parts in the air circuit. Cleaning should be as

often as necessary to keep coil clean. Use a brush, vacuum

cleaner attachment, or other suitable means. If water is used

to clean coil, be sure power to the unit is shut off prior to

cleaning.

NOTE: Exercise care when cleaning the coil so that the coil

fins are not damaged.

Do not permit the hot condenser air discharge to be

obstructed by overhanging structures or shrubs.

GAS BURNER

Periodically (at least annually at the beginning of each heat-

ing season) make a visual check of the main burner flame.

TO CLEAN BURNERS

Remove them from the furnace as explained in BURNER

INSTRUCTIONS. Clean burners with hot water applied along

top of the burner.

COMBUSTION AIR DISCHARGE

Visually inspect discharge outlet periodically to make sure

that the buildup of soot and dirt is not excessive. If necessary,

clean to maintain adequate combustion air discharge.

CLEANING FLUE PASSAGES AND HEATING ELEMENTS

With proper combustion adjustment, the heating element of a

gas fired furnace will seldom need cleaning. If the element

should become sooted, it can be cleaned as follows:

1. Remove the burner assembly as outlined in BURNER

INSTRUCTIONS.

2. Remove the screws holding the top of the flue collector

box. Carefully remove the top of the flue collector box.

The draft wheel, housing, and draft motor can remain

assembled to the flue box top, if cleaning of these com-

ponents is not required.

3. This will provide access to flue baffles, then remove the

flue baffles from the tube interiors. To remove, the flue

baffles, remove the stainless steel screws from the vest

panel. Refer to Figure 48.

4. Using a wire brush on a flexible wand, brush out the

inside of each heat exchanger from the burner inlet and

flue outlet ends.

5. Brush out the inside of the flue collector box, and the flue

baffles.

6. Run the wire brush down the vent hoods from the flue

collector end.

7. If soot build-up is particularly bad, remove the vent motor

and clean the wheels and housings. Run the wire brush

down the flue extension at the outlet of the vent hous-

ings.

8. After brushing is complete, blow all brushed areas with

air or nitrogen. Vacuum as needed.

9. Replace parts in the order they were moved in steps 1 to

4.

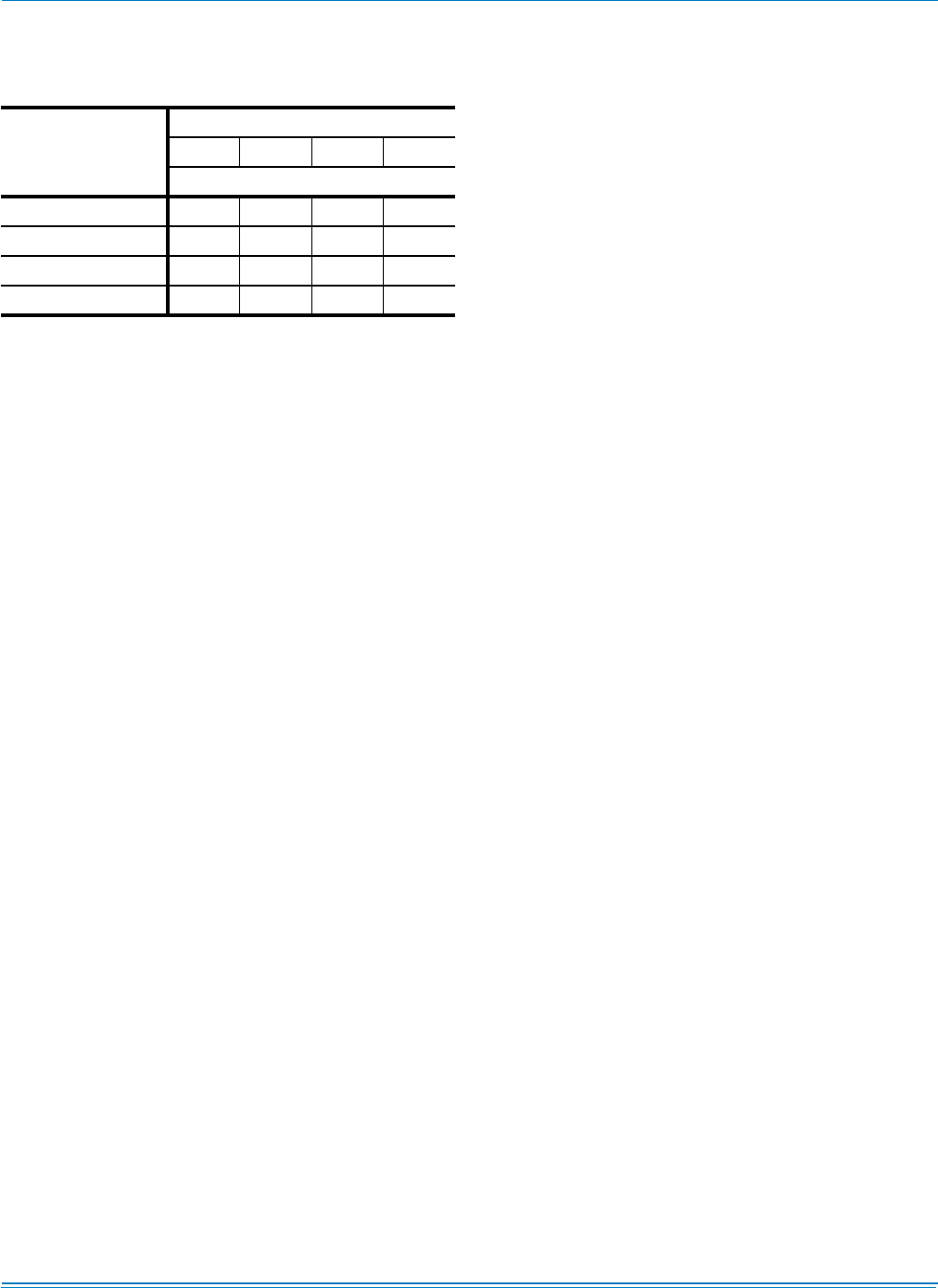

TABLE 59: INDOOR BLOWER BEARING

LUBRICATION SCHEDULE

Shaft Size (Inches)

Operating Speed (RPM)

500 1000 1500 2000

Relubrication Cycle (Months)

1-1/16 - 1-7/16 6666

1-1/2 - 1-3/4 6664

1-7/8 - 2-3/16 6644

2 -1/4 - 3 6442