882108-YIM-B-1012

Johnson Controls Unitary Products 17

7. A 1/8 inch N.P.T. plugged tapping, accessible for test

gage connection, must be installed immediately

upstream of the gas supply connection to the furnace.

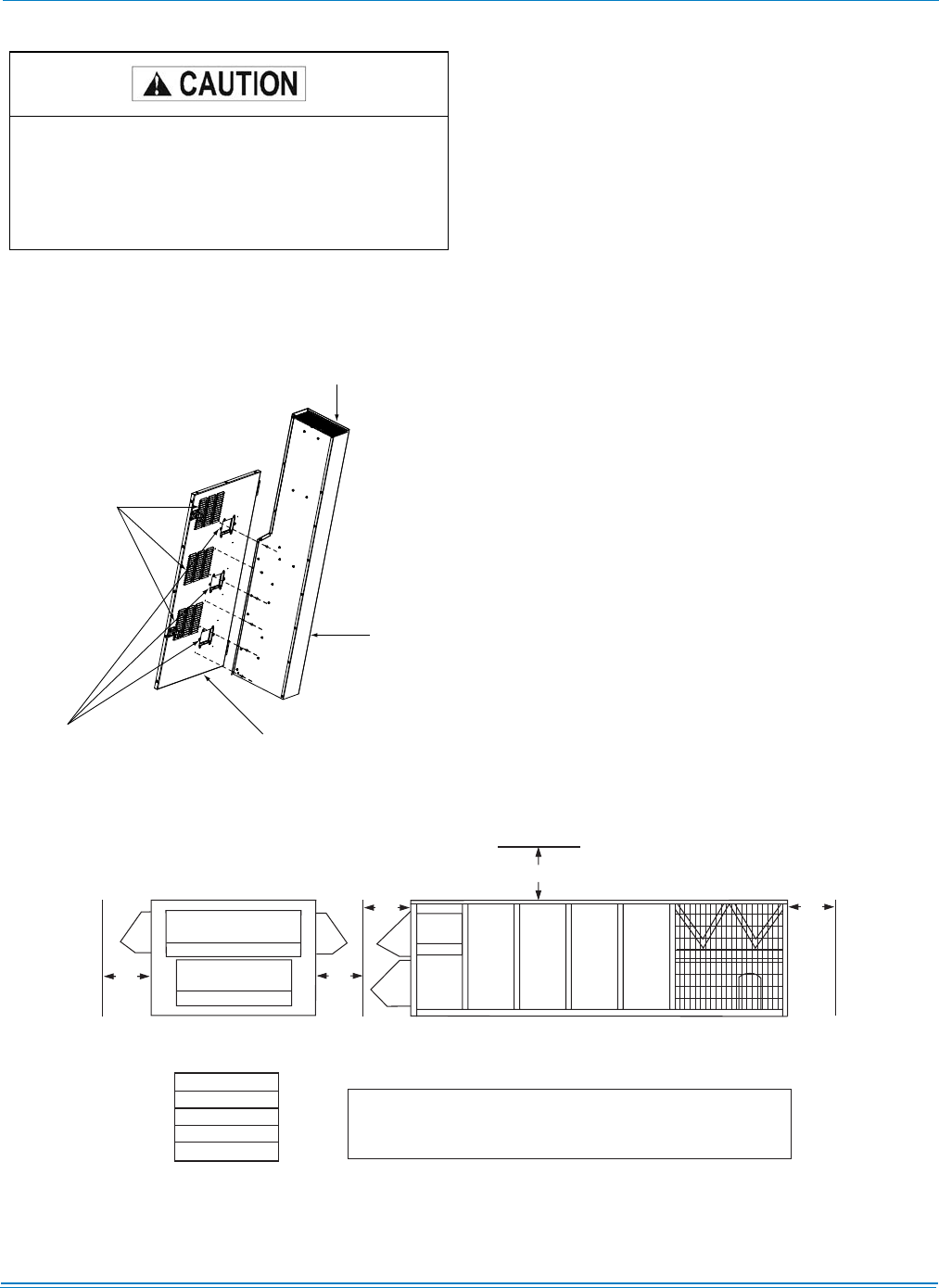

VENT AND COMBUSTION AIR

NOTE: All the hoods and hardware are shipped within the

evaporator section. Each hood must be properly

attached to the furnace doors to assure proper

operation and compliance with CSA/ETL safety cer-

tification. (Refer to Figure 7.)

The products of combustion are discharged horizontally

through hooded openings in the gas heat access doors.

(Figure 7)

1. Remove the shipping covers that are attached to the

heat section door covering the flue outlets.

2. Locate the flue which is shipped in the evaporator sec-

tion.

3. Place the flue over the flue outlet and attach with screws

provided.

4. Refer to the Gas Furnace Operation Instruction in the

Start-up Section of this manual for further instructions.

Disconnect gas piping from unit when leak testing

at pressures greater than 0.5 psig. Pressures

greater than 0.5 psig will cause gas valve damage

resulting in a hazardous condition. If gas valve is

subjected to pressure greater than 0.5 psig, it must

be replaced.

FIGURE 7 - VENT AND COMBUSTION AIR

HOODS

COMBUSTION

AIR INLET

REMOVE SHIPPING

LABELS PRIOR TO

VENT INSTALLATION

HEAT SECTION DOOR

VENT FLUE

ASSEMBLY

EXHAUST VENT OUTLET

FIGURE 8 - CLEARANCES

60"

60"

60"

10'

60"

60"

60"

60"

60"

10'

* Front is the side with access to the Electrical/Gas Controls

LEFT

RIGHT

END

END

REAR

LEFT

RIGHT

REAR

FRONT

TOP

NOTE: DO NOT use the unit roof to support any type of

structure bracing.

FRONT