882108-YIM-B-1012

64 Johnson Controls Unitary Products

GAS FURNACE OPERATING

INSTRUCTIONS

TO LIGHT THE MAIN BURNERS

1. Turn off electric power to unit.

2. Turn space temperature sensor to lowest setting.

3. Turn gas valve knobs to on position (Refer to Figure 25).

4. Turn on electric power to unit.

5. On Constant Volume units, set space setpoint to warmer

or cooler as desired. (If sensor set point temperature is

above room temperature, the main burners will ignite). If

a second stage of heat is called for, the main burners for

second stage heat will ignite for the second stage heat.

For VAV units set morning warm-up thermostat far above

the return air temperature and cycle the time clock OFF,

then ON.

TO SHUT DOWN

1. Turn off electric power to unit.

2. Depress knob of gas valve while turning to off position or

move switch to off position. (Refer to Figure 25).

POST-START CHECKLIST (GAS)

After the entire control circuit has been energized and the

heating section is operating, make the following checks:

1. Check for gas leaks in the unit piping as well as the sup-

ply piping.

2. Check for correct manifold gas pressures. See Checking

Gas Input.

3. Check the supply gas pressure. It must be within the lim-

its shown on rating nameplate. Supply pressure should

be checked with all gas appliances in the building at full

fire. At no time should the standby gas pressure exceed

13 inches, nor the operating pressure drop below 6

inches. If gas pressure is outside these limits, contact the

local gas utility for corrective action.

MANIFOLD GAS PRESSURE ADJUSTMENT

Small adjustments to the gas flow may be made by turning

the pressure regulator adjusting screw on the automatic gas

valve. Refer to Figure 25.

Adjust as follows:

1. Remove the cap on the regulator. It's located next to the

push-on electrical terminals.

2. To decrease the gas pressure, turn the adjusting screw

counterclockwise.

3. To increase the gas pressure, turn the adjusting screw

clockwise.

NOTE: The factory manifold pressure for each furnace

module is 3.50 IWG.

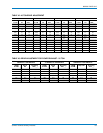

TABLE 44: DRIVE ADJUSTMENT FOR POWER EXHAUST - 30 & 40 TON

7.5 HP Motor & 852 RPM Drive 10 HP Motor & 976 RPM Drive 15 HP Motor & 1069 RPM Drive

% RPM

& CFM

REQ’D

PD (in)

Browning

2B5V_ _

% RPM

& CFM

REQ’D

PD (in)

Browning

2B5V_ _

% RPM

& CFM

REQ’D

PD (in)

Browning

2B5V_ _

96.4 5.3 52 93.7 5.9 58 94.2 6.5 64

100.0 (Std.) 5.5 54 96.8 6.1 60 97.1 6.7 66

103.6 5.7 56 100.0 (Std.) 6.3 62 100.0 (Std.) 6.9 68

107.3 5.9 58 103.2 6.5 64 102.9 7.1 70

110.9 6.1 60 106.3 6.7 66 108.7 7.5 74

114.5 6.3 62 109.5 6.9 68 117.4 8.1 80

Each furnace module is equipped with an auto-

matic re-ignition system. DO NOT attempt to man-

ually light the burners.