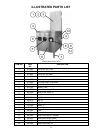

2

INSTALLATION INSTRUCTIONS

*GAS SERVICE CONNECTIONS:

The boiler is factory adjusted for a gas input of 100, 200 & 300K BTU/HR at the pressure indicated.

Please read the rating plate behind the Lift-Off Front Panel. If this plate is marked for a different gas than

that supplied, notify your dealer immediately. Install an external gas supply shut off valve in a visible and

accessible location. If the unit is placed at the minimum side clearances rather than the optimum side

clearances, the only acceptable location for the gas supply shut off valve is under the unit in the space

provided by the legs.

Use new iron or steel pipe complying with the latest ANSI Standard for Wrought-Steel and Wrought-Iron

Pipe, B36, properly threaded, reamed and free from chips, oil and dirt. If pipe dope is used, apply a mod-

erate amount leaving two end threads bare. Pipe dope must be resistant to LP gas. Connect the gas line

into the bottom (inlet) side of the shutoff valve. The supply pressure must be at least 1” (25mm) water

column higher than the manifold or regulator pressure for proper functioning of the regulator. If it is not

check the supply pipe for blockage or excessive pressure drop and make necessary corrections.

Perform a gas leak test of all newly-made joints, as well as those leading to the main gas control valve.

Use a soap solution, DO NOT USE FLAME.

Natural gas units are equipped with a pressure regulator factory adjusted to give 4” (102mm) water col-

umn manifold pressure.

Propane gas units are equipped with a pressure regulator, factory adjusted, to give 10” (254mm) water

column manifold pressure.

ONLY A LICENSED GAS FITTER SHOULD MAKE GAS LINE CONNECTIONS.

*ELECTRIC SERVICE CONNECTION:

Connect boiler controls to 110/120 volt AC, 60Hz, single phase branch circuit rated 15 amps capacity, using the

three prong plug provided.

* Gas and Electrical connections should be made by licensed tradesmen only.

a)

b)

c)

d)

e)

f)