Page 23

System Operation Monitor LED Troubleshooting Codes

Status LED Condition Status LED Troubleshooting InformationStatus LED Description

*Flash code number corresponds to a number of LED flashes, followed by a pause, and then repeated. Reset ALERT flash code

by removing 24VAC power from monitor; last code will display for 1 minute after monitor is powered on.

NOTE − Code 8 is not used.

Maintenance

The GCSX15 unit should be inspected annually by a

qualified service technician to ensure proper operation.

Filters

Not supplied. Inspect once a month. Replace disposable,

or clean permanent−type, as necessary. DO NOT replace

permanent type with disposable.

Motors

Indoor, outdoor fan and vent motors are permanently

lubricated and require no further lubrication. Motors

should be cleaned yearly to prevent the accumulation of

dust and dirt on the windings or motor exterior.

Coil

Dirt and debris should not be allowed to accumulate on the

coil surfaces or other parts in the air conditioning circuit.

Cleaning should be performed as often as necessary. Use

a brush, vacuum cleaner attachment, or other suitable

means. If water is used to clean the coil, be sure the power

to unit is shut off prior to cleaning.

NOTE − Care should be used when cleaning the coil so that

the coil fins are not damaged.

Do not permit the hot condenser air discharge to be

obstructed by overhanging structures or shrubs.

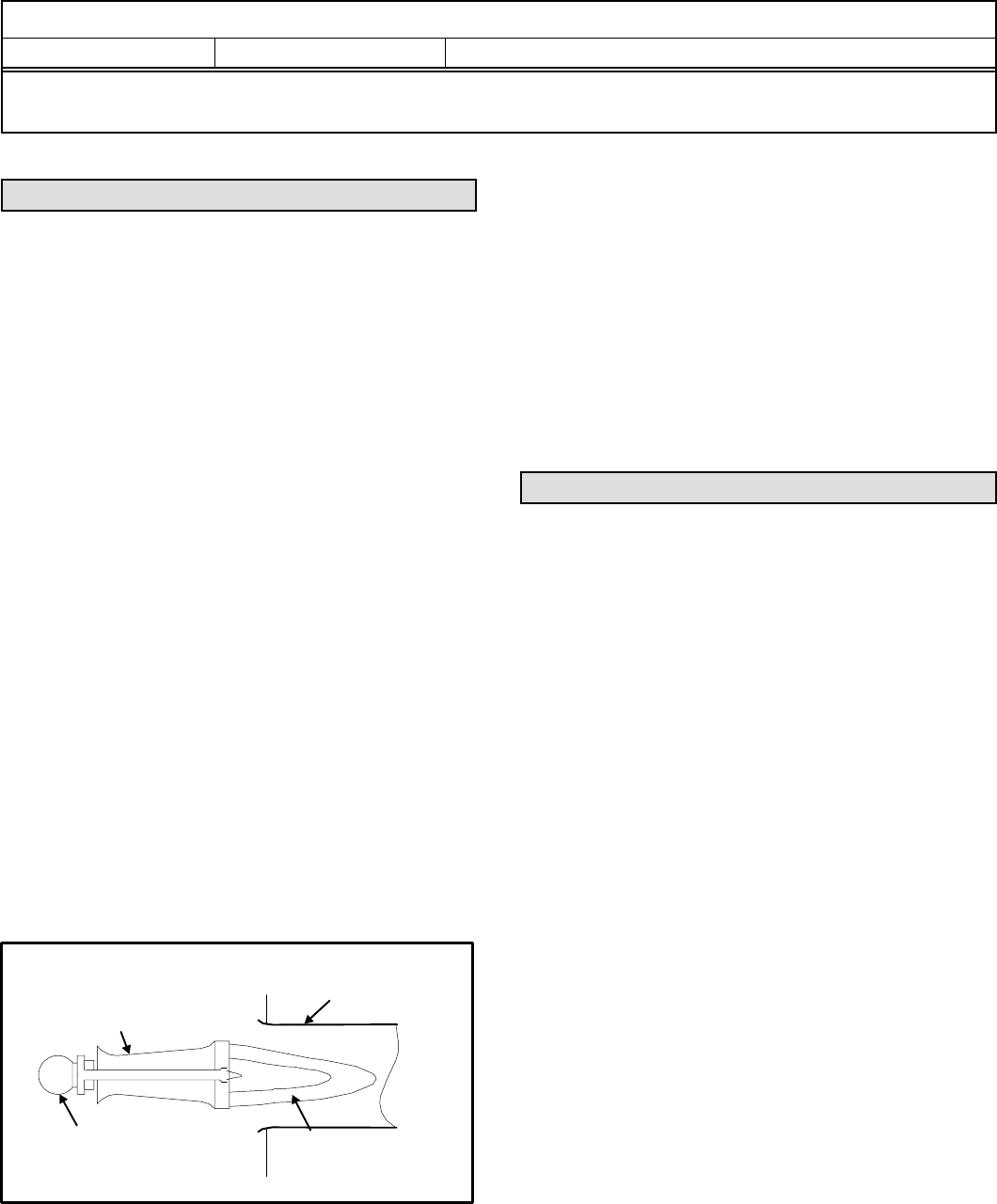

To Clean Burners

Light the burners and allow unit to operate for a few

minutes to establish normal burning conditions. Observe

the burner flames. Compare this observation to figure 16

to determine if flame is properly adjusted. Flame should

be predominantly blue in color and strong in appearance.

Verify that all burners are lit and that the flame does not

impinge on the sides of the heat exchanger.

Burner Flame

Figure 16

Burner

Heat

Exchanger

Burner Flame

(Blue Only)

Gas

Manifold

Distorted flame or yellow tipping of the natural gas flame

(or long yellow tips on LP/propane flame) may be caused

by one or more of the following: lint or dirt inside the

burner or burner ports; lint or dirt at the air inlet between

the burner and manifold pipe; or an obstruction over the

burner orifice.

Use a soft brush or vacuum to clean the affected areas.

Vent Outlet

Visually inspect vent outlet periodically to make sure that the

there is no buildup of soot and dirt . If necessary, clean to

maintain adequate opening to discharge flue products.

Planned Service

You should expect a service technician to check the

following items during an annual inspection. Power to the

unit must be shut off for the service technician’s safety.

S Fresh air grilles and louvers Must be open and

unobstructed to provide combustion air.

S Burners must be inspected for rust, dirt, or signs of

water.

S Exhaust pipe must be inspected for signs of water,

damaged Rust or disconnected joints.

S Unit appearance must be inspected for rust, dirt, signs

of water, burnt or damaged wires, or components. A

good coat of auto wax can extend the appearance.

S Blower access door must be properly in place.

S Return air duct must be properly attached and provide

an air seal to the unit.

S Operating performance Ċ Unit must be observed

during operation to monitor proper performance of the

unit and the vent system.

S Combustion gases Ċ Flue products must be analyzed

and compared to the unit specifications.

Problems detected during the inspection may make it

necessary to temporarily shut down the furnace until the

items can be repaired or replaced.

Pay attention to your unit. Situations can arise between

annual furnace inspections that may result in unsafe

operation. For instance, items innocently stored next to the

unit may obstruct the combustion air supply. This could

cause incomplete combustion and the production of

carbon monoxide gas.