Page 10

Compressors

Units are shipped with the compressor mountings

factory−adjusted and ready for operation.

CAUTION

Do not loosen compressor mounting bolts.

Gas Supply and Piping

Check the unit rating plate to confirm whether unit is

equipped for use with natural gas or LP/propane. If

conversion is required use the approved conversion kit.

NOTE − Units are shipped equipped for natural gas, but can

be converted to LP/propane with a conversion kit.

Conversion must be performed by an approved

licensed pipe fitter or technician.

All LP/propane gas equipment must conform to the safety

standards of the National Fire Protection Association.

Complete information regarding tank sizing for

vaporization, recommended regulator settings, and pipe

sizing is available from most regulator manufacturers and

LP/propane gas suppliers.

Proper sizing of gas piping depends on the cubic feet per

hour of gas flow required, specific gravity of the gas and

length of run. In the United States, the current National Fuel

Gas Code Z223.1 should be followed in all cases unless

superseded by local codes or gas company requirements.

Refer to tables 2 and 3. In Canada, refer to the current CSA

B.149 installation codes.

Table 2

Gas Heat Application Data

Unit

Heating Size

Input Rating

(Btu)

Output Rating

(Btu)

Gas Capacity*

(FT

3

/ HR)

68 67,500 54,000 63

83 82,500 66,000 77

90 90,000 72,000 84

110 110,000 88,000 102

138 137,500 110,000 128

*Based on 1075 Btu per cubic foot of natural gas.

Before connecting piping, check with gas company or

authorities having jurisdiction for local codes or

requirements. When installing gas supply piping, length

of run from gas meter must be considered in

determining pipe size for 0.5 inch w.c. maximum

pressure drop. Do not use supply pipe smaller than unit

gas connection. For natural gas unit, supply pressure at

the unit gas connection must be a minimum of 5 inches

w.c. and a maximum of 10.5 w.c. For LP/propane gas

units, supply pressure at the unit gas connection must

be a minimum of 11 inches w.c. and a maximum of 13.0

inches w.c.

Table 3

Gas Pipe Capacity−FT

3

/ HR

Length in Feet

Nominal Iron Pipe Size (inches)

1/2 in. 3/4 in. 1 in. 1−1/4 in.

10 132 278 520 1050

20 92 190 350 730

30 73 152 285 590

40 63 130 245 500

50 56 115 215 440

60 50 105 195 400

70 46 96 180 370

80 43 90 170 350

90 40 84 160 320

100 38 79 150 305

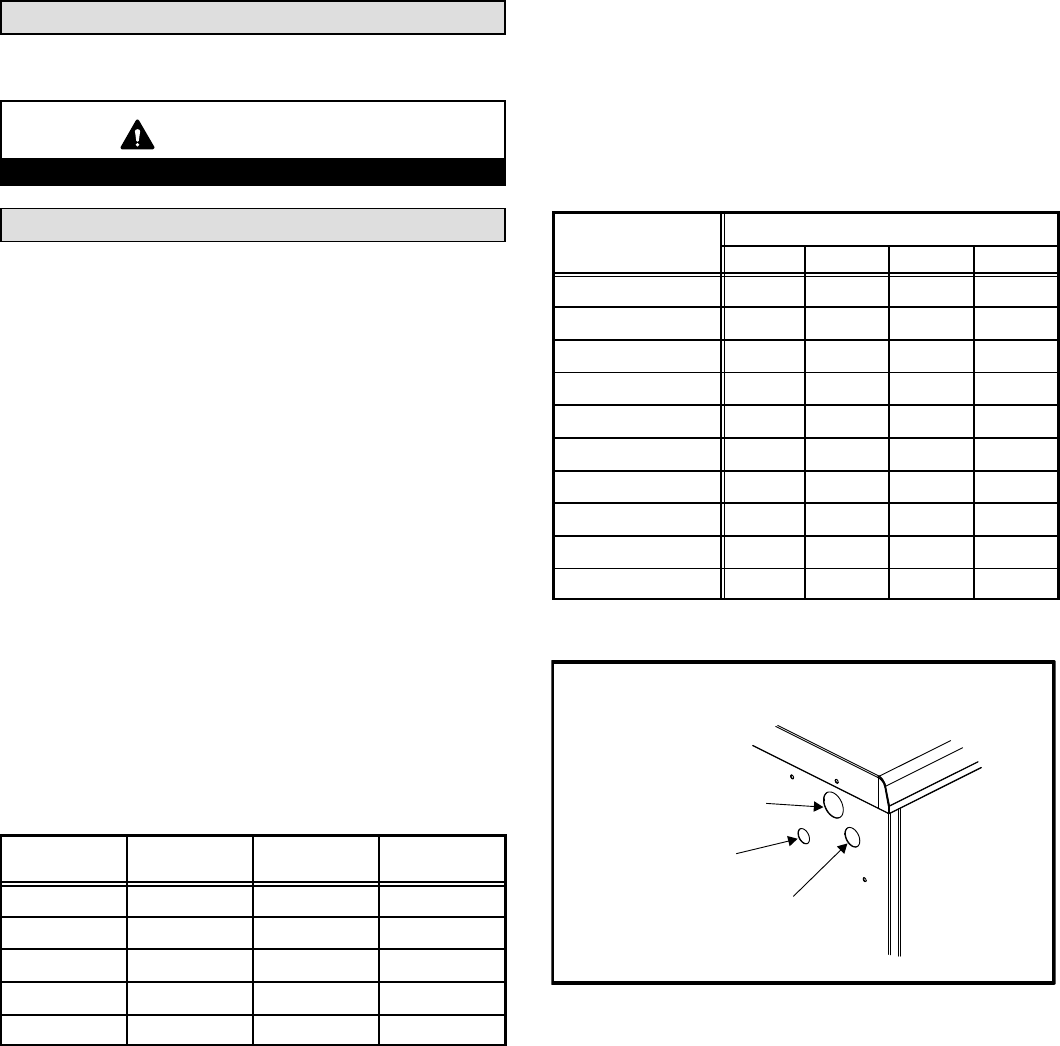

The gas supply piping should be routed through the

grommet on the side of the unit. Refer to figure 7.

Figure 7

Gas Piping and Electrical Conduit Access

Gas Line Entry

Thermostat

Entry

Line Voltage

Entry

When making piping connections, a drip leg should be

installed on vertical runs to serve as a trap for sediment or

condensate. A 1/8 inch N.P.T. tap accessible for test gauge

connection must be provided in field piping upstream from

gas supply connection to unit. Install a ground joint union

between gas control manifold and the manual main

shut−off valve. See figure 8.

Compounds used on threaded joints of gas piping shall be

resistant to the action of propane/LP gases.