Page 24

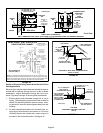

TYPICAL AIR INTAKE PIPE CONNECTIONS

DOWNFLOW NON−DIRECT VENT APPLICATIONS

(Right−Hand Exit in Downflow Applications Shown)

FIGURE 28

PLUG

(Must be

glued in

place)

6 in. Max.

PLUG

(Must be

glued in

place)

Downflow Additive Flloor Base

18 in.

Downflow

Evaporator

Coil

2"

2" SWEEP

ELL

2" SWEEP ELL

INTAKE DEBRIS

SCREEN

(Provided)

INTAKE

DEBRIS

SCREEN

(Provided)

NOTE − Debris screen and sweep ell may be rotated, so that

screen may be positioned to face forward, backward or to the side.

1 − Use field−provided materials and the factory−provided

air intake screen to route the intake piping as shown in

figures 27 and 28. Maintain a minimum clearance of 3"

(76mm) around the air intake opening. The air intake

opening (with the protective screen) should always be

directed either downward or straight out. Use 2" pipe

and fittings only and make sure that the air intake does

not extend more than 6" beyond the G61MP cabinet.

The air intake connector must not be located near

the floor. To avoid this complication in downflow

applications which do not include a downflow

evaporator coil, the intake air routing should be modi-

fied as shown in figure 28.

2 − Use a #7 sheet metal screw to secure the intake pipe to

the connector, if desired. A pilot indentation is provided in

the slip connector to assist in locating and starting the fas-

tener.

3 − Glue the provided 2" ABS plug into the unused ABS air

intake connector on the opposite side of the cabinet with

ABS or all purpose solvent cement.